KGN-carried collagen/chitosan/sodium hyaluronate composite scaffold

A sodium hyaluronate and composite scaffold technology, applied in the field of biomedicine, can solve the problems of adverse reactions, inability to delay or stop the OA process, high price, etc., achieve good biocompatibility, improve the mechanical properties of collagen, and the preparation process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Accurately weigh 200 mg of PLGA and dissolve in 4 mL of dichloromethane, and shake to form an oil phase (O);

[0034] (2) Accurately weigh 10 mg KGN and place it in 1 mL of a mixture of ultrapure water and methanol, and dissolve it completely at 37°C to form an inner water phase (W1); the volume ratio of ultrapure water to methanol is 1 :1;

[0035] (3) Slowly inject the inner water phase (W1) in step (2) into the oil phase (O) in step (1) and continue to stir and emulsify for 10 min, so that it can be evenly dispersed to form a colostrum emulsion (W1 / O);

[0036] (4) Drop the colostrum emulsion (W1 / O) described in step (3) into 50 mL of 1wt% PVA solution containing 5 mL of 0.1wt% Tween-20 at 60 drops / min to form the external water phase (W2), Continuous stirring to form double milk (W1 / O / W2);

[0037] (5) Fully centrifuge the double emulsion (W1 / O / W2) described in step (4), discard the supernatant, wash and centrifuge with ultrapure water repeatedly for 3 times, ...

Embodiment 2

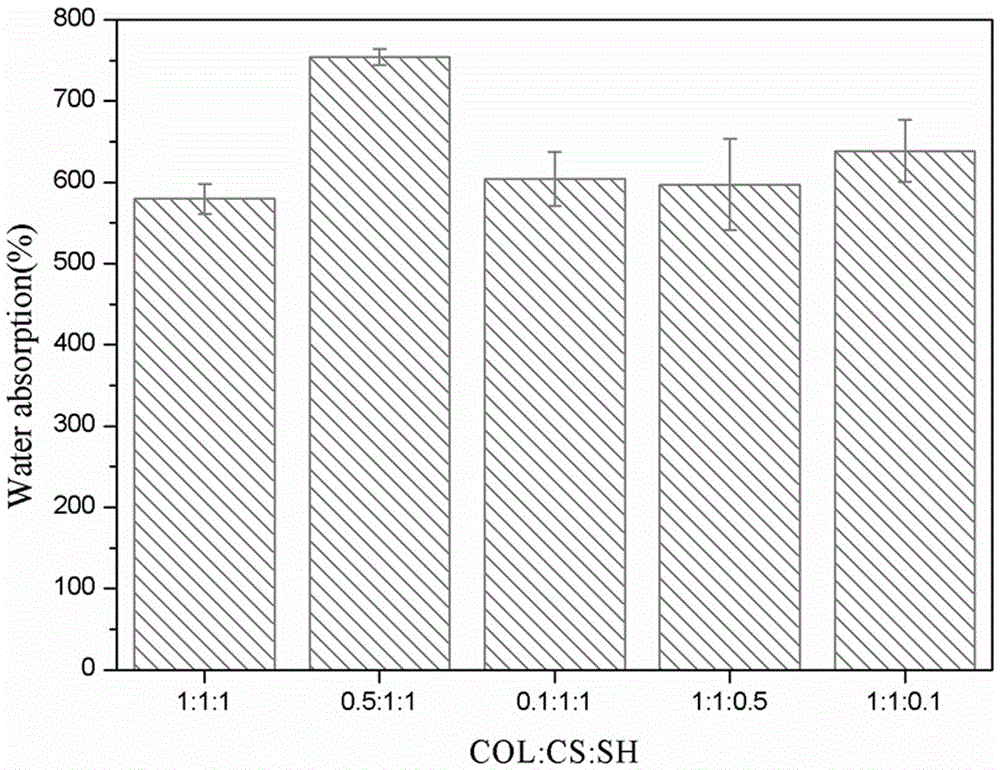

[0045] In step (6) of Example 1, change bovine tendon collagen to fish skin collagen; in step (10), change the volume ratio of 0.6% COL, 1% CS and 1% HAS solution to 5:10 : 10, the other steps are the same as in Example 1, preparing the collagen / chitosan / sodium hyaluronate composite scaffold loaded with KGN.

Embodiment 3

[0047] In step (6) of Example 1, change bovine tendon collagen to pig skin collagen; in step (10), change the volume ratio of 0.6% COL, 1% CS and 1% HAS solution to 1:10 : 10, the other steps are the same as in Example 1, preparing the collagen / chitosan / sodium hyaluronate composite scaffold loaded with KGN.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com