Anti-stacking nitrogen doped three-dimensional graphene and preparation method thereof

A graphene and nitrogen-doped technology, applied in chemical instruments and methods, hydrogen production, inorganic chemistry, etc., can solve problems such as performance impact, achieve good stability, high catalytic efficiency, and be conducive to sustainable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

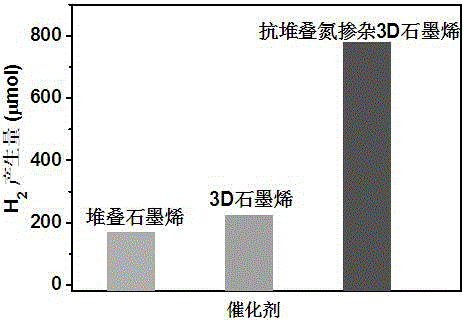

[0028] Add 80 mL of 1 mg / mL graphene oxide aqueous solution into the reactor, then heat it in water at 180 °C for 10 h, then centrifuge and wash the obtained solid three times, and dry it at 60 °C for 12 h to obtain stacked graphene;

[0029] Take 10 mg of stacked graphene and 40 mg of Eosin Y solid into 70 mL of aqueous solution, sonicate for 30 min, add 0.50 mL of 10 mM H 2 PtCl 6 and 10 mL of triethanolamine, and degas the reaction system while maintaining a constant temperature of 5 °C. Then, the reaction system was irradiated with visible light with a wavelength greater than 420 nm for 30 min. Afterwards, the system was degassed to keep the system in a vacuum state. The reaction system was irradiated with visible light with a wavelength greater than 420 nm, and the hydrogen production was detected online by gas chromatography, with argon as the carrier gas. After 2 h of light irradiation, the hydrogen production in the system was detected.

Embodiment 2

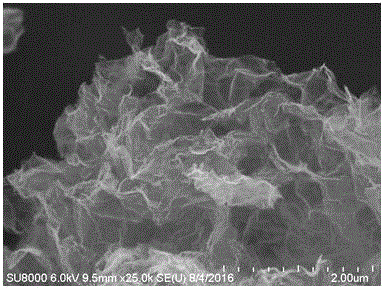

[0031] Add 15 mL of 10 mg / mL graphene oxide aqueous solution into the reaction kettle, and then hydroheat at 180 °C for 10 h, and then freeze-dry the obtained columnar graphene to obtain 3D graphene;

[0032] Take 10 mg of prepared 3D graphene and 40 mg of Eosin Y solid into 70 mL solution, sonicate for 30 min, add 0.50 mL of 10mM H 2 PtCl 6 and 10 mL of triethanolamine, and degas the reaction system while maintaining a constant temperature of 5 °C. Then, the reaction system was irradiated with visible light with a wavelength greater than 420 nm for 30 min. Afterwards, the system was degassed to keep the system in a vacuum state. The reaction system was irradiated with visible light with a wavelength greater than 420 nm, and the hydrogen production was detected online by gas chromatography, with argon as the carrier gas. After 2 h of light irradiation, the hydrogen production in the system was detected.

Embodiment 3

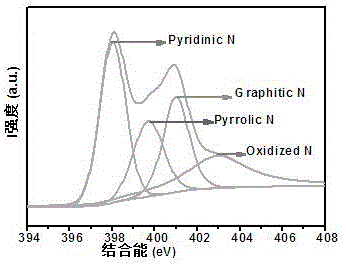

[0034] Add 350 mg melamine and 1.5 mL 37wt% formaldehyde to 15 mL 10 mg / mL graphene oxide aqueous solution, heat at 180 °C for 10 h, then centrifuge, wash, and dry to obtain stack-resistant graphene oxide. Put anti-stacking graphene oxide into a tube furnace, calcined at 750 °C for 5 h under the protection of nitrogen atmosphere (heating rate is 5 °C per minute), and then cool down naturally to obtain anti-stacking nitrogen-doped 3D graphene;

[0035] Take 10 mg of anti-stacking nitrogen-doped 3D graphene and 40 mg of Eosin Y solid into 70 mL of solution, sonicate for 30 min, add 0.50 mL of 10mM H 2 PtCl 6 and 10 mL of triethanolamine, and degas the reaction system while maintaining a constant temperature of 5 °C. Then, the reaction system was irradiated with visible light with a wavelength greater than 420 nm for 30 min. Afterwards, the system was degassed to keep the system in a vacuum state. The reaction system was irradiated with visible light with a wavelength greater ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com