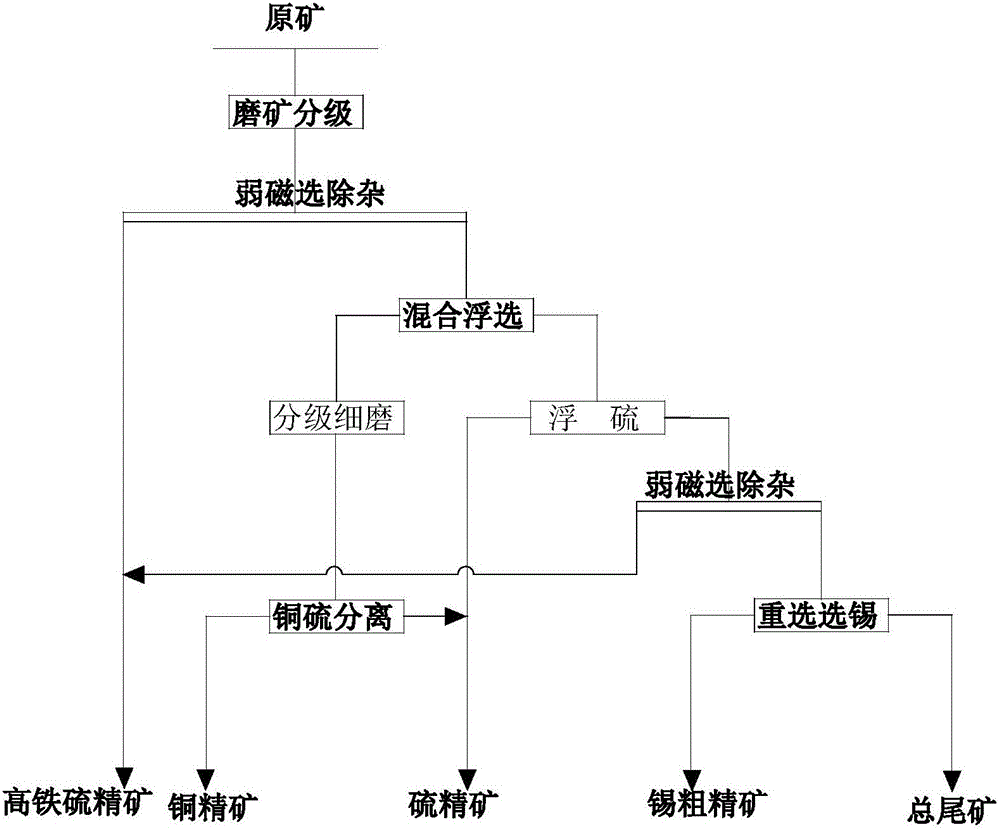

Beneficiation method for tin-copper paragenetic sulphide ore rich in pyrrhotite

A technology for pyrrhotite and beneficiation methods, which is applied in chemical instruments and methods, flotation, wet separation, etc., can solve the problems of low recovery rate, large specific gravity, and influence on sorting indicators, and achieves reduction of operating load and efficiency. The effect of production consumption, impurity content reduction and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Aiming at the tin-copper symbiotic sulfide ore with a tin grade of 0.3-1.1% and a copper grade of 0.4-1.2% in Gejiu, Yunnan, the following beneficiation method is adopted, and the steps are as follows:

[0023] (1) The first magnetic separation and impurity removal: the copper-tin symbiotic sulfide ore is crushed and ground to make the original ore -200 The mesh accounts for 60%, the concentration is 35%, and then it enters the wet permanent magnetic separator for sorting, the sorting magnetic field strength is 1500Gs, and the high-iron pyrrhotite concentrate is produced;

[0024] (2) Mixed flotation: The magnetic tailings of the above step (1) are subjected to one-coarse and two-sweep mixed flotation to produce crude copper concentrate; based on the weight of the ore, the reagent system is as follows:

[0025] Rough selection: collector mixed base xanthate 100g / t, foaming agent 2# oil 20g / t;

[0026] The first sweep and the second sweep are the same: mixed base xanthate 45g / t, ...

Embodiment 2

[0038] For the raw ore of tin-copper intergrowth sulfide ore with a tin grade of 0.8% and a copper grade of 0.9%, the following beneficiation method is adopted, and the steps are as follows:

[0039] (1) The first magnetic separation and impurity removal: the copper-tin symbiotic sulfide ore is crushed and ground to make the original ore -200 The mesh accounts for 50%, the concentration is 40%, and then it enters into a wet permanent magnetic separator for sorting, and the sorting magnetic field strength is 1600Gs to produce high-iron pyrrhotite concentrate;

[0040] (2) Mixed flotation: The magnetic tailings of the above step (1) are subjected to one-coarse and two-sweep mixed flotation to produce crude copper concentrate; based on the weight of the ore, the reagent system is as follows:

[0041] Rough selection: Collector mixed base xanthate 150g / t, 2# oil 30g / t, stir for 3 minutes;

[0042] The first sweep and the second sweep are the same: mixed base xanthate 30g / t, 2# oil 15g / t, s...

Embodiment 3

[0054] For the raw ore of tin-copper symbiosis sulfide ore with a tin grade of 0.5% and a copper grade of 0.7%, the following beneficiation method is adopted, and the steps are as follows:

[0055] (1) The first magnetic separation and impurity removal: the copper-tin symbiotic sulfide ore is crushed and ground to make the original ore -200 The mesh accounts for 65%, the concentration is 30%, and then it enters the wet permanent magnetic separator for sorting, the sorting magnetic field strength is 1800Gs, and the high-iron pyrrhotite concentrate is produced;

[0056] (2) Mixed flotation: The magnetic tailings of the above step (1) are subjected to one-coarse and two-sweep mixed flotation to produce crude copper concentrate; based on the weight of the ore, the reagent system is as follows:

[0057] Rough selection: Collector mixed base xanthate 50g / t, 2# oil 15g / t, stir for 4 minutes;

[0058] The first sweep and the second sweep are the same: mixed base xanthate 60g / t, 2# oil 18g / t, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com