Composite material for operating table and its processing technology

A processing technology and composite material technology, applied in the field of light industrial textiles, can solve the problems of low bonding fastness and poor peel strength of composite materials, and achieve the effects of ensuring stability, improving quality and precise control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

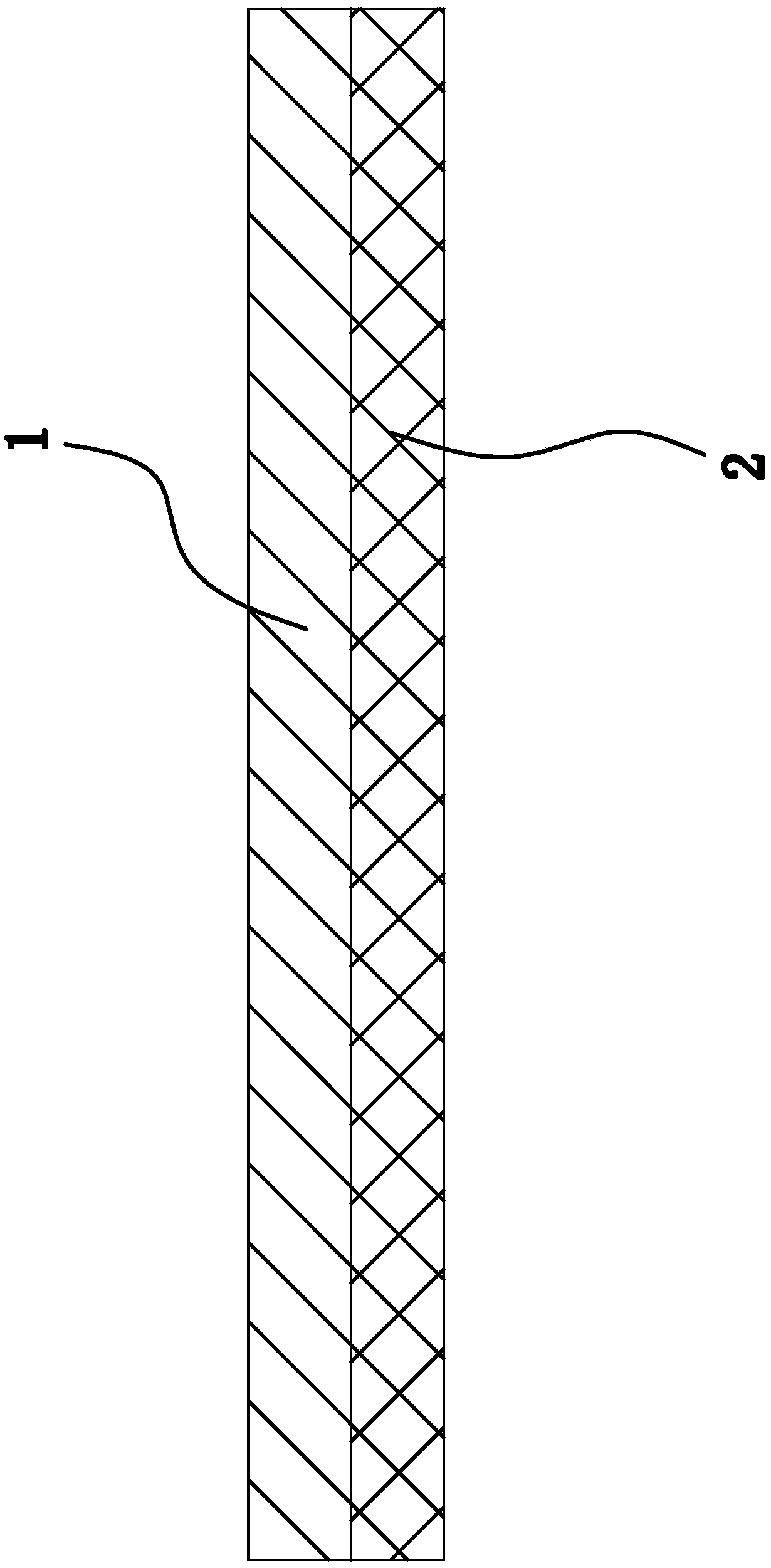

[0064] Such as figure 1 As shown, the composite material for the operating table is formed by laminating the PVC film 1 and the skeleton material layer 2 at a high temperature of 200°C. Wherein, the skeleton material layer 2 is in the shape of mesh cloth and is made of 55D high-strength polyester yarn and is woven by biaxial warp knitting; the PVC film 1 has a thickness of 18 yarns, and it is made of the following raw materials in parts by weight: PVC resin powder 100; plasticizer DINP50; epoxy soybean oil 1; barium zinc stabilizer 2; antibacterial agent 1; rutile titanium dioxide 0.2. In this embodiment, the preferred antibacterial agent is a pyridylisothiourea compound.

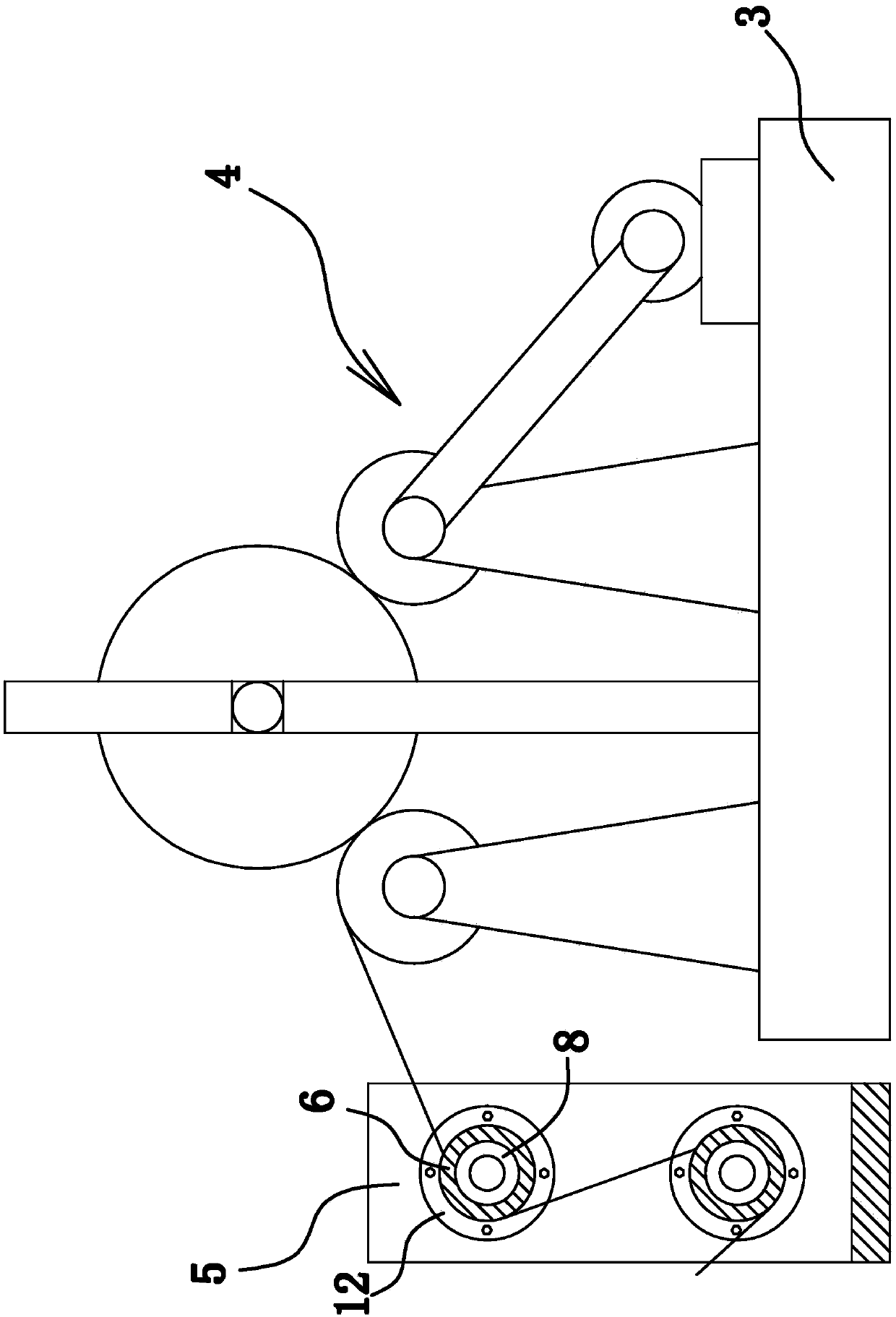

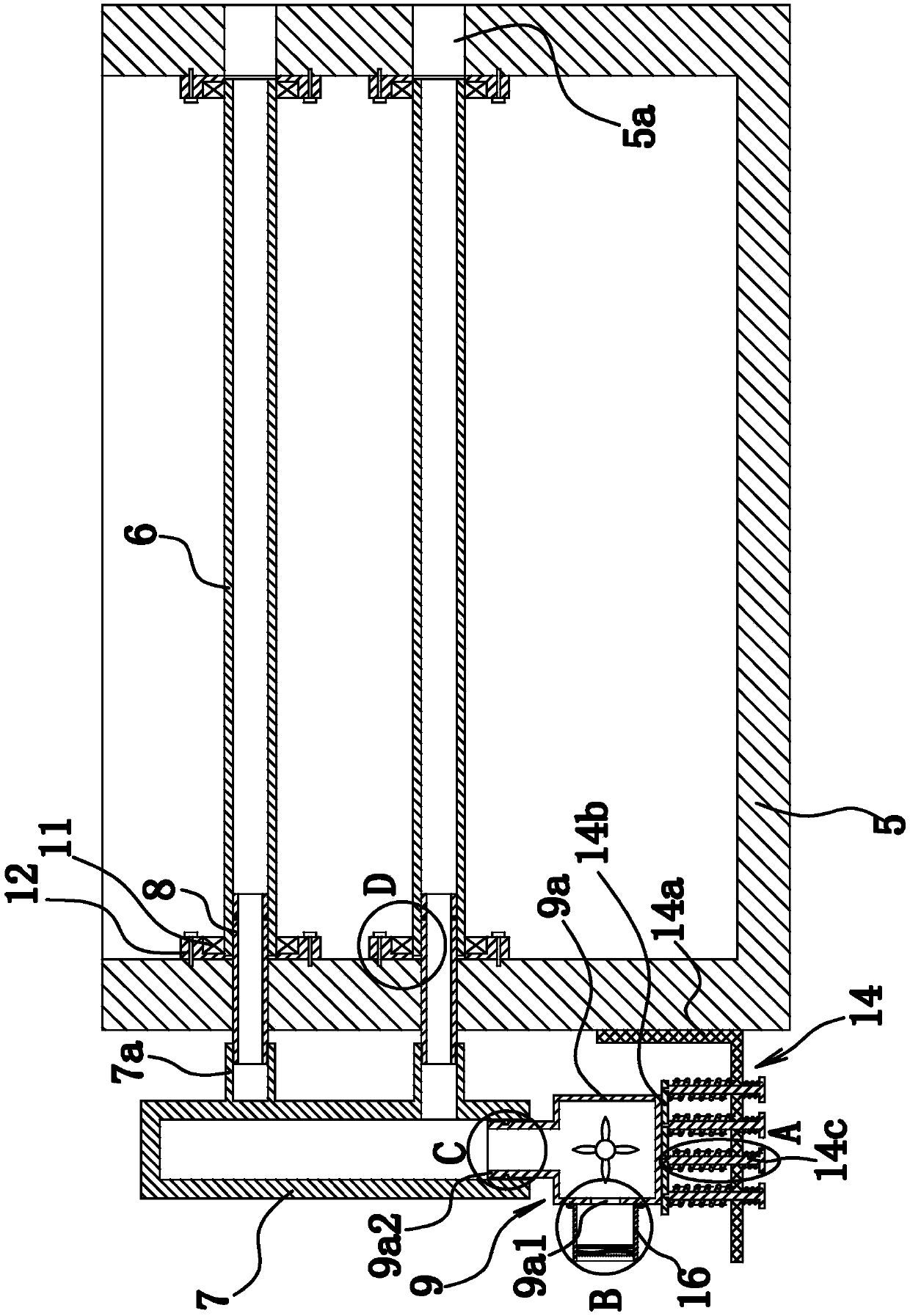

[0065] The processing technology of the composite material for the operating table is composed of three parts: the processing technology of the skeleton material layer 2, the calendering technology of the PVC film 1 and the product processing technology. The processing technology of the skeleton material ...

Embodiment 2

[0097] The structure and principle of the present embodiment two are basically the same as the embodiment one, the difference is that the PVC film 1 is made from the following raw materials in parts by weight: PVC resin powder 100; plasticizer DINP55; epoxy soybean oil 3; barium Zinc stabilizer 5; antibacterial agent 2; rutile titanium dioxide 0.6.

[0098] The PVC film 1 calendering process comprises the following steps: A, batching weighing: each raw material is weighed batching by weight;

[0099] B. Stirring and mixing: Pour the ingredients into the mixer, control the temperature to 90°C, the stirring speed is 125r / min, and the stirring time is 100s; then raise the temperature to 130°C, the stirring speed is 590r / min, and the stirring time is 250s; then cool down to 65°C, the stirring speed is 350r / min, and the stirring time is 180s;

[0100] C. Banbury mixing: the control temperature is 175°C, and the pressurization time of the top bolt is 6.5 minutes;

[0101] D. Two-r...

Embodiment 3

[0113] The structure and principle of the third embodiment are basically the same as the first embodiment, except that the PVC film 1 is made from the following raw materials in parts by weight: PVC resin powder 100; plasticizer DINP60; epoxy soybean oil 5; barium Zinc stabilizer 8; antibacterial agent 3; rutile titanium dioxide 1.

[0114] The PVC film 1 calendering process comprises the following steps: A, batching weighing: each raw material is weighed batching by weight;

[0115] B. Stirring and mixing: Pour the ingredients into the mixer, control the temperature to 100°C, the stirring speed is 150r / min, and the stirring time is 100s; then raise the temperature to 135°C, the stirring speed is 630r / min, and the stirring time is 250s; then cool down to 70°C, the stirring speed is 400r / min, and the stirring time is 180s;

[0116] C. Banbury mixing: the control temperature is 180°C, and the pressurization time of the top bolt is 7 minutes;

[0117] D. Two-roll pre-plasticiza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com