Method for regulating ZSM-5 molecular sieve morphology

A ZSM-5, molecular sieve technology, applied in the direction of crystalline aluminosilicate zeolite, borane silicone crystalline aluminosilicate zeolite, etc., can solve the problems affecting the quality and yield of ZSM-5 molecular sieve, and the operable range of the amount of electrolyte added. Small, multi-waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

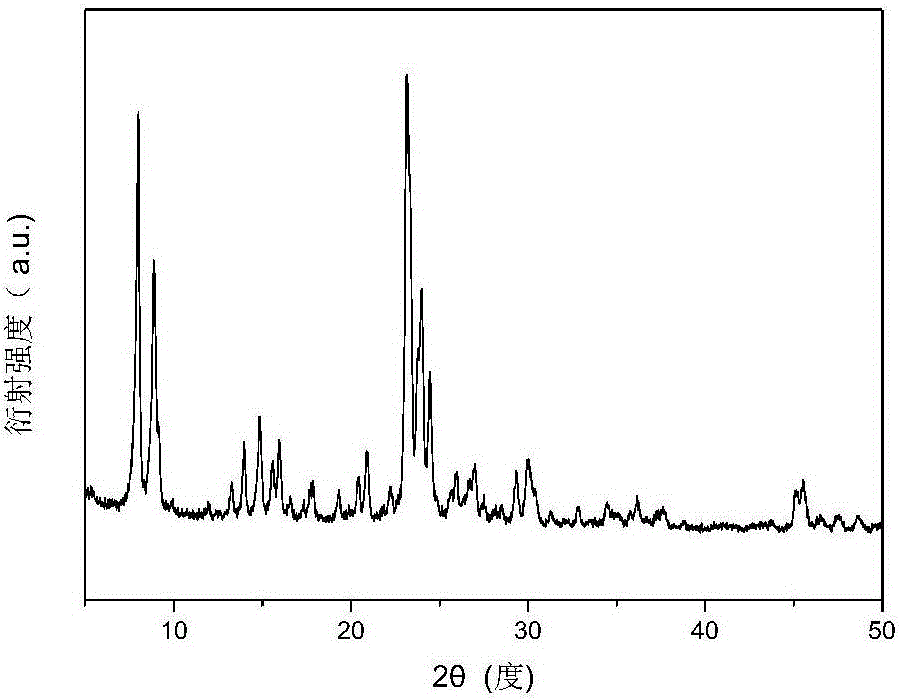

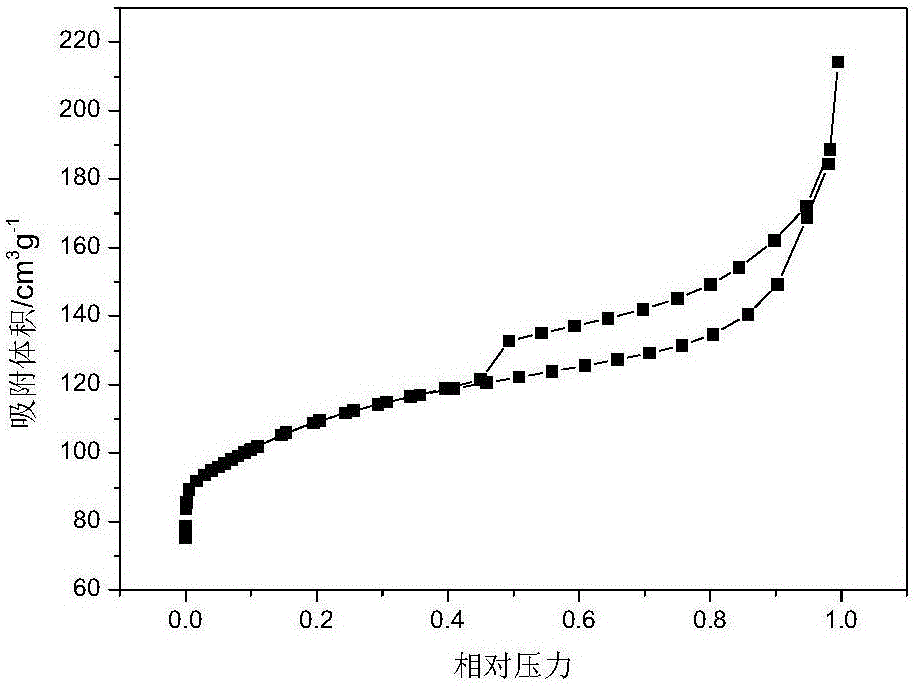

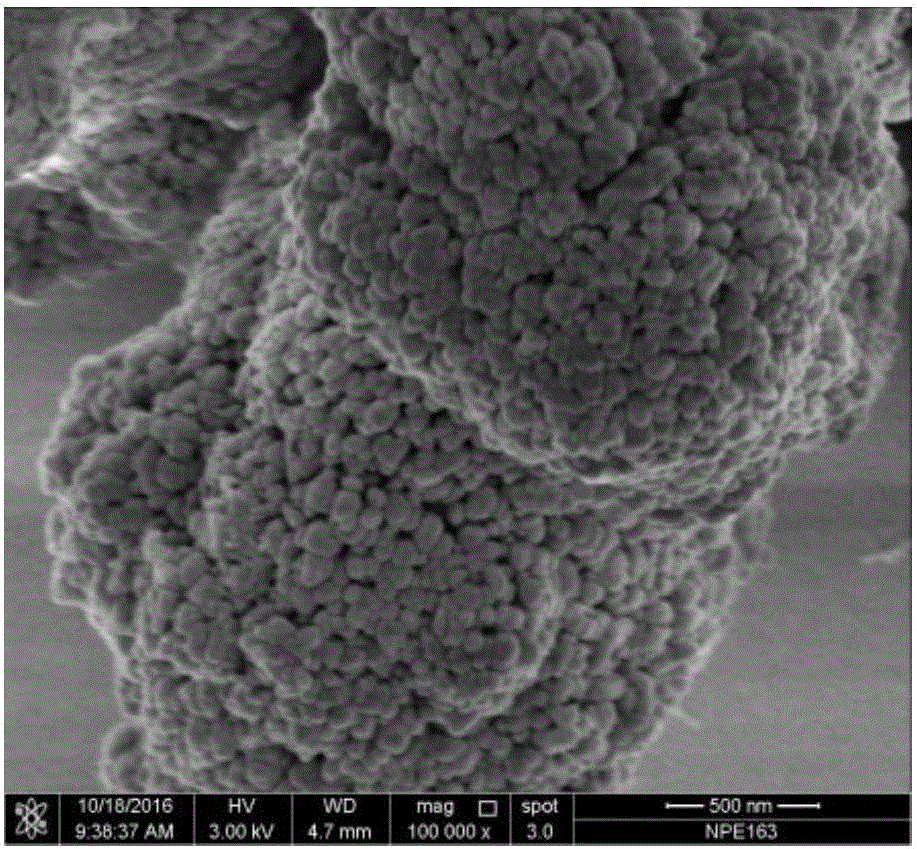

[0034] Dissolve 1.5g of sodium metaaluminate in 93g of water, then add 2.15g of disodium hydrogen phosphate dodecahydrate to a transparent and clear solution, and finally add 60g of silica sol, mix and stir for 20min to obtain a uniform solution, the molar ratio of each component is SiO 2 :Al 2 o 3 :P 2 o 5 :H 2 O=1:0.02:0.01:25.24. Then an aerosol is formed by an aerosol generator, dried at 200°C to obtain silicon-aluminum-phosphorus oxide, 1g of silicon-aluminum-phosphorus oxide is placed in a 10ml stainless steel synthesis kettle lined with polytetrafluoroethylene, and then 0.6428g of tetrapropyl Ammonium hydroxide aqueous solution (tetrapropyl ammonium hydroxide mass fraction 25%), SiO in silicon aluminum phosphorus oxide 2 The molar ratio to tetrapropylammonium hydroxide and water is 1:0.05:1.7, sealed at 170°C for crystallization reaction for 48 hours, and the resulting solid product is dried at 100°C, then roasted at 540°C for 10h to remove Template agent to obtai...

Embodiment 2

[0036] Dissolve 1.5g of sodium metaaluminate in 147g of water, then add 4.3g of disodium hydrogen phosphate dodecahydrate to a transparent and clear solution, and finally add 60g of silica sol, mix and stir for 20min to obtain a uniform solution, the molar ratio of each component is SiO 2 :Al 2 o 3 :P 2 o 5 :H 2 O=1:0.02:0.02:35.48. Then an aerosol is formed by an aerosol generator, dried at 200°C to obtain silicon-aluminum-phosphorus oxide, 1g of silicon-aluminum-phosphorus oxide is placed in a 10ml stainless steel synthesis kettle lined with polytetrafluoroethylene, and then 0.6428g of tetrapropyl Ammonium hydroxide aqueous solution (tetrapropyl ammonium hydroxide mass fraction 25%), SiO in silicon aluminum phosphorus oxide 2 The molar ratio to tetrapropylammonium hydroxide and water is 1:0.05:1.7, sealed at 170°C for crystallization reaction for 48 hours, and the resulting solid product is dried at 100°C, then roasted at 540°C for 10h to remove Template agent to obtai...

Embodiment 3

[0038] Dissolve 1.5g of sodium metaaluminate in 256g of water, then add 8.6g of disodium hydrogen phosphate dodecahydrate to a transparent and clear solution, and finally add 60g of silica sol, mix and stir for 20min to obtain a uniform solution, the molar ratio of each component is SiO 2 :Al 2 o 3 :P 2 o 5 :H 2 O=1:0.02:0.04:55.96. Then an aerosol is formed by an aerosol generator, dried at 200°C to obtain silicon-aluminum-phosphorus oxide, 1g of silicon-aluminum-phosphorus oxide is placed in a 10ml stainless steel synthesis kettle lined with polytetrafluoroethylene, and then 0.6428g of tetrapropyl Ammonium hydroxide aqueous solution (tetrapropyl ammonium hydroxide mass fraction 25%), SiO in silicon aluminum phosphorus oxide 2 The molar ratio to tetrapropylammonium hydroxide and water is 1:0.05:1.7, sealed at 170°C for crystallization reaction for 48 hours, and the resulting solid product is dried at 100°C, then roasted at 540°C for 10h to remove Template agent to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com