Process device and method for realizing zero discharge of desulfurization waste liquid based on electric drive ion membrane

A technology of desulfurization waste liquid and process method, which is applied in the direction of chemical instruments and methods, gaseous effluent wastewater treatment, water/sewage multi-stage treatment, etc., which can solve the high investment and treatment cost of waste liquid treatment, which cannot meet the needs of enterprises and society , Poor economic and social benefits, etc., to achieve the effect of reducing pretreatment and terminal evaporation equipment, solving the high cost of zero emission, reducing equipment investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

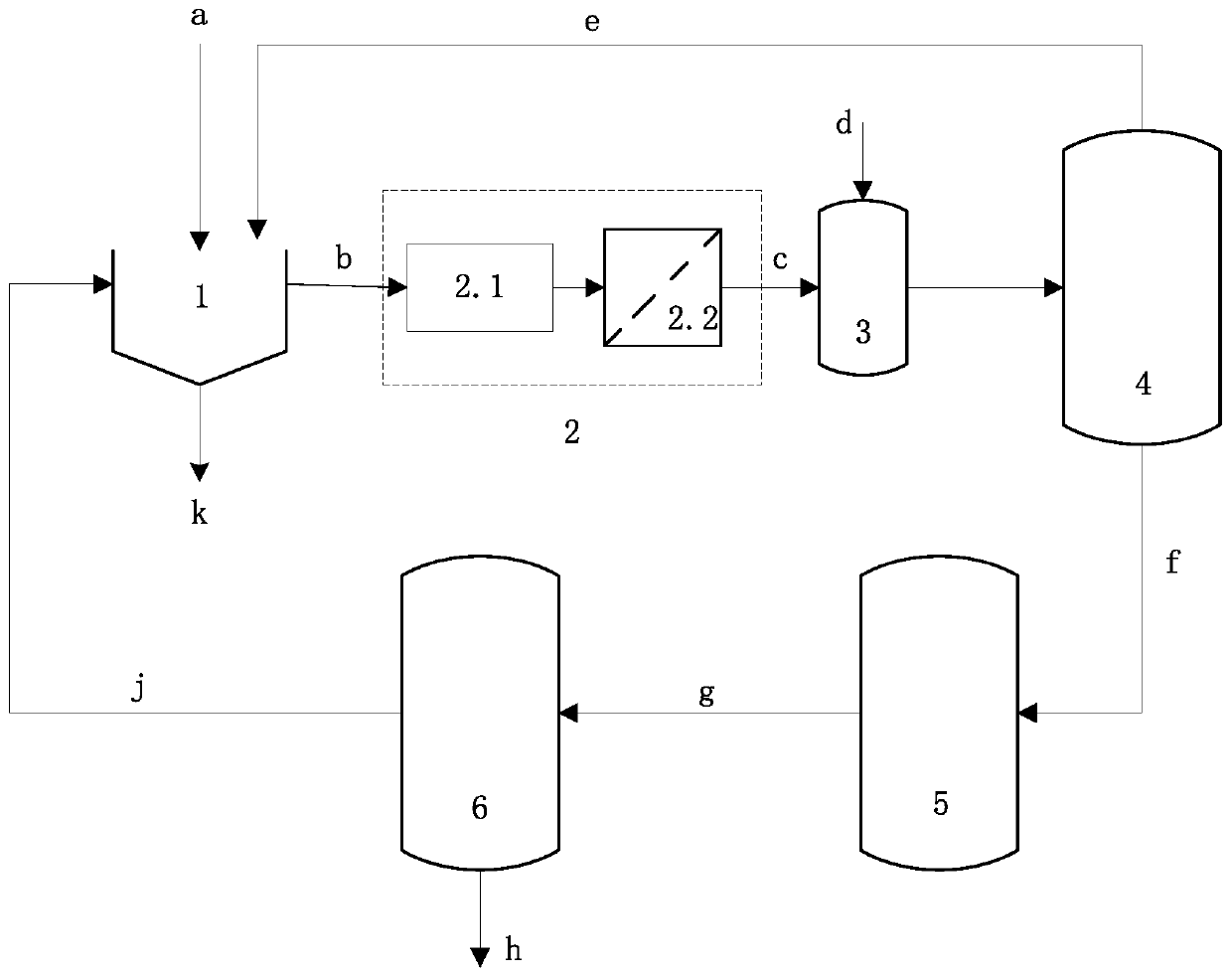

[0052] A process device for realizing zero discharge of desulfurization waste liquid based on electric drive ion membrane, including desulfurization waste liquid clarifier 1, sedimentation filter equipment 2, dilution tank 3, electric drive ion membrane equipment for separation of multivalent ions 4, homogeneous concentration electric Drive ionic membrane equipment 5, bipolar membrane electric drive ionic membrane equipment 6;

[0053] The sedimentation filtration equipment 2 includes a sedimentation tank 2.1 and a fiber filter 2.2;

[0054] The desulfurization waste liquid clarification tank 1 is connected to the sedimentation tank 2.1 of the sedimentation filtration equipment 2 through a flow-carrying pipeline, the sedimentation tank 2.1 of the sedimentation filtration equipment 2 is connected to the fiber filter 2.2 of the sedimentation filtration equipment 2, and the fiber filter 2.2 of the sedimentation filtration equipment 2 The dilution tank 3 is connected to the diluti...

Embodiment 2

[0068] A process device for realizing zero discharge of desulfurization waste liquid based on electric drive ion membrane, same as embodiment 1.

[0069] A process method for realizing zero discharge of desulfurization waste liquid based on electric drive ionic membrane, using the above-mentioned device, including the following steps:

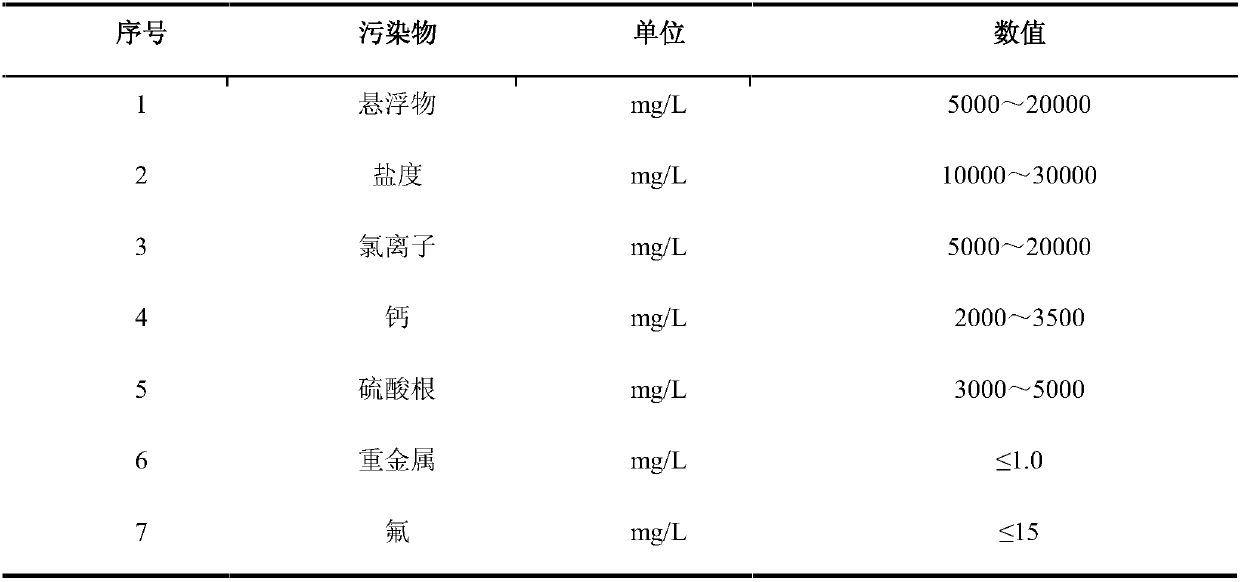

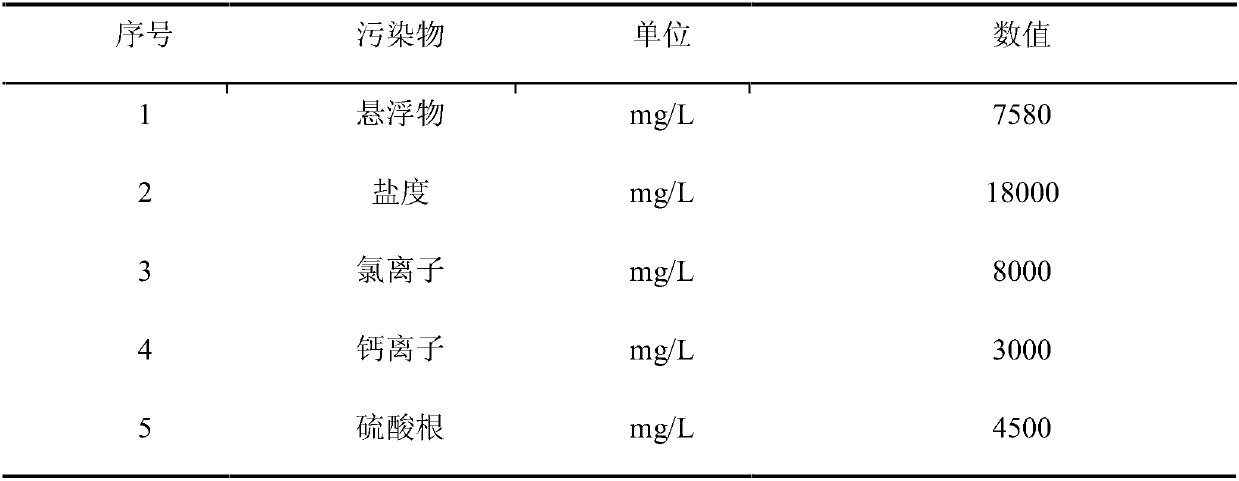

[0070] (1) The desulfurization waste liquid a from the desulfurization tower enters the desulfurization waste liquid clarification tank 1 for preliminary clarification, removes a large amount of gypsum k accumulated in the desulfurization waste liquid a, and obtains the desulfurization waste liquid clarification liquid b, and the desulfurization waste liquid clarification liquid b enters Precipitation and filtration equipment 2 performs precipitation and filtration treatment to remove suspended solids in the desulfurization waste liquid to obtain desulfurization waste liquid filtrate c;

[0071] Precipitation and filtration treatment, the speci...

Embodiment 3

[0082] A process device for realizing zero discharge of desulfurization waste liquid based on electric drive ion membrane, same as embodiment 1.

[0083] A process method for realizing zero discharge of desulfurization waste liquid based on electric drive ionic membrane, using the above-mentioned device, including the following steps:

[0084] (1) The desulfurization waste liquid a from the desulfurization tower enters the desulfurization waste liquid clarification tank 1 for preliminary clarification, removes a large amount of gypsum k accumulated in the desulfurization waste liquid a, and obtains the desulfurization waste liquid clarification liquid b, and the desulfurization waste liquid clarification liquid b enters Precipitation and filtration equipment 2 performs precipitation and filtration treatment to remove suspended solids in the desulfurization waste liquid to obtain desulfurization waste liquid filtrate c;

[0085] Precipitation and filtration treatment, the speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com