Lead-free high-insulation ceramic coating zinc oxide arrester valve disc and preparation method thereof

一种陶瓷涂层、高绝缘的技术,应用在电阻器、电阻制造、压敏电阻器芯体等方向,能够解决浪费电能、结合性不好、使用温度不高等问题,达到避免工艺繁琐、扩大使用范围、使用温度高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

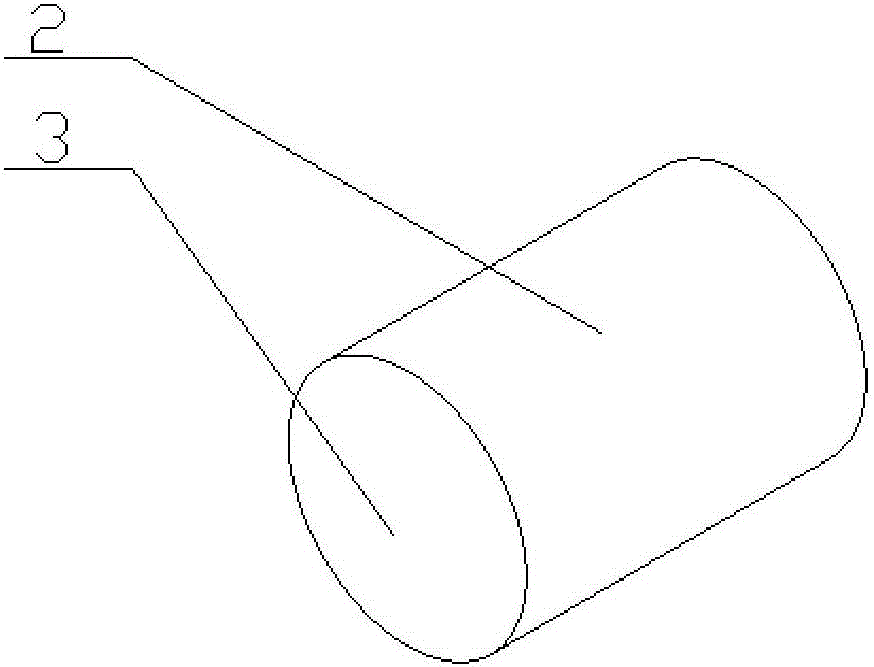

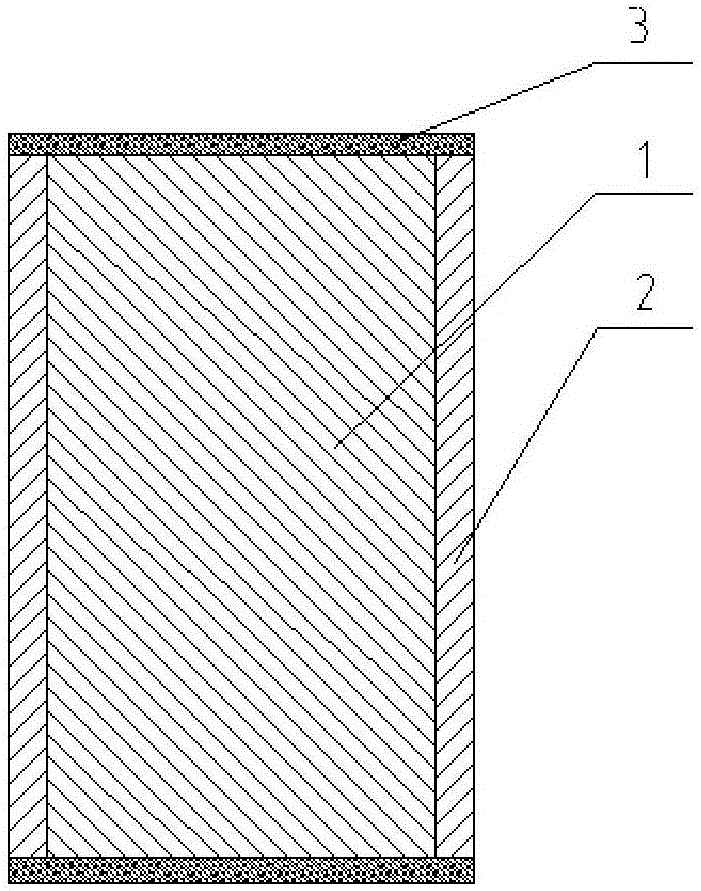

Image

Examples

Embodiment 1

[0031] 1. The raw materials are configured according to the following weight percentages: ZnO: 88.4%; Bi2O3: 2.5%; Co3O4: 0.6%; Mn3O4: 0.4%; Sb2O3: 7%; NiO: 0.3%; SiO2: 0.8%.

[0032] 2. Prepare ceramic coating powder according to the above ratio. The ratio of the total powder mass, deionized water mass, and agate ball mass is 3:2:4. Add ammonium polyacrylate dispersant, and its dosage is the total powder mass 0.5% of the mass was put into a 10L polyurethane ball mill tank, and ball milled with a tank ball mill for 48 hours, and the speed was set at 450r / min. The ball-milled slurry is taken out, sieved, put into an oven for drying, and then pulverized with a pulverizer and sieved; thus the ZnO ceramic coating powder is prepared.

[0033] 3. Take a 10% PVA solution by mass percentage and a 1% ammonium polyacrylate dispersant in an amount of the total mass of the powder to obtain a mixed solution and sieve it. Take the above-mentioned ceramic coating powder, the total weight of...

Embodiment 2

[0036] 1. The raw materials are configured according to the following weight percentages: ZnO: 89.2%; Bi2O3: 2.0%; Co3O4: 1.0%; Mn3O4: 0.8%; Sb2O3: 5.0%; NiO: 0.5%; SiO2: 1.5%.

[0037] 2. Prepare ceramic coating powder according to the above ratio. The ratio of the total powder mass, deionized water mass, and agate ball mass is 3:2:4. Add ammonium polyacrylate dispersant, and its dosage is the total powder mass 1.0% of the mass was put into a 10L polyurethane ball mill tank, and ball milled with a tank ball mill for 48 hours at a speed of 450r / min. The ball-milled slurry is taken out, sieved, put into an oven for drying, and then pulverized with a pulverizer and sieved; thus the ZnO ceramic coating powder is prepared.

[0038] 3. Take a 6.5% PVA solution by mass percentage and a 1% ammonium polyacrylate dispersant in an amount of the total mass of the powder to obtain a mixed solution and sieve it. Take the above-mentioned ceramic coating powder, the total weight of the powd...

Embodiment 3

[0041] 1. The raw materials are configured according to the following weight percentages: ZnO: 86%; Bi2O3: 1.0%; Co3O4: 0.5%; Mn3O4: 0.2%; Sb2O3: 3%; NiO: 0.2%; SiO2: 1%.

[0042] 2. Prepare ceramic coating powder according to the above ratio. The ratio of the total powder mass, deionized water mass, and agate ball mass is 3:2:4. Add ammonium polyacrylate dispersant, and its dosage is the total powder mass 0.5% of the mass was put into a 10L polyurethane ball mill tank, and ball milled with a tank ball mill for 48 hours, and the speed was set at 450r / min. The ball-milled slurry is taken out, sieved, put into an oven for drying, and then pulverized with a pulverizer and sieved; thus the ZnO ceramic coating powder is prepared.

[0043] 3. Take a 5% PVA solution by mass percent and a 1% ammonium polyacrylate dispersant with an amount of the total mass of the powder to obtain a mixed solution and sieve it. Take the above-mentioned ceramic coating powder, the total weight of the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid containing ratio | aaaaa | aaaaa |

| solid containing ratio | aaaaa | aaaaa |

| solid containing ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com