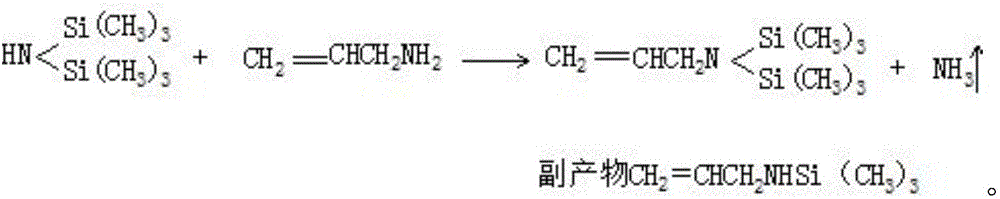

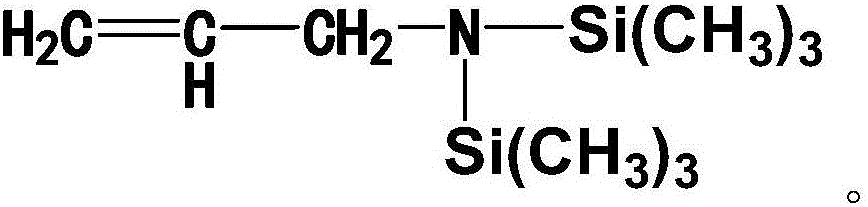

N,N-bis(trimethylsilyl)allylamine and preparation method thereof

A technology of trimethylsilyl and allylamine, applied in the field of N, can solve the problems of corrosion of production equipment, high reaction cost and high price, and achieve the effects of prolonging service life, high conversion rate of raw materials and reducing reaction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Install a stirrer, a constant pressure dropping funnel, a reflux condenser and a thermometer on the four-necked flask, control the temperature in the four-necked flask at 10°C, feed nitrogen into the flask until the bottle is full of nitrogen, and dissolve 28.5g of allylamine Add 1.2g of trifluoromethanesulfonic acid into the flask, add 96.6g of hexamethyldisilazane into the constant pressure dropping funnel, start stirring, and after stirring for 10min, dropwise drop hexamethyldisilazane into the flask, The dropping time is 30 minutes, and after the dropping, the temperature is raised to 100° C. and kept for 4 hours.

[0044] Then cool down to room temperature, at a temperature of 80 ° C, under reduced pressure distillation under the condition of 58mmHg to obtain 82.1gN, N-bis(trimethylsilyl)allylamine product, the calculated yield of the product is 81% , The purity of N,N-bis(trimethylsilyl)allylamine was 99.0%.

Embodiment 2

[0046] Install a stirrer, a constant pressure dropping funnel, a reflux condenser and a thermometer on the four-necked flask, control the temperature in the four-necked flask at 28°C, feed nitrogen into the flask until the bottle is full of nitrogen, and dissolve 28.5g of allylamine Add 1.2g of concentrated sulfuric acid into the flask, add 96.6g of hexamethyldisilazane into the constant pressure dropping funnel, start stirring, and after stirring for 10 minutes, add hexamethyldisilazane dropwise into the flask at a constant speed, and the dropping time After 30 minutes, the temperature was raised to 110°C and kept for 5 hours after dropping.

[0047] Cool down to room temperature then, be 85 ℃ in temperature, underpressure distillation under the condition of 65mmHg obtain 81.7gN, N-bis(trimethylsilyl)allylamine product, calculate the yield of product and be 80.2% , The purity of N,N-bis(trimethylsilyl)allylamine was 98.6%.

Embodiment 3

[0049]Install a stirrer, a constant pressure dropping funnel, a reflux condenser and a thermometer on the four-necked flask, control the temperature in the four-necked flask at 28°C, feed nitrogen into the flask until the bottle is full of nitrogen, and dissolve 28.5g of allylamine and 1.2 titanium tetrachloride were added to the flask, 96.6g of hexamethyldisilazane was added to the constant pressure dropping funnel, and stirring was started. After stirring for 10 minutes, hexamethyldisilazane was added dropwise to the flask at a constant speed, and The time is 40 minutes, and after the dripping is completed, the temperature is raised to 110° C. and kept for 5.5 hours.

[0050] Cool down to room temperature then, be 85 ℃ in temperature, underpressure distillation obtain 81.2g N under the condition of pressure 65mmHg, N-bis(trimethylsilyl) allyl amine product, the yield that calculates product is 80.14% , The purity of N,N-bis(trimethylsilyl)allylamine was 98.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com