Material of automobile thermal-insulating and sound-insulating plate and preparation method of material

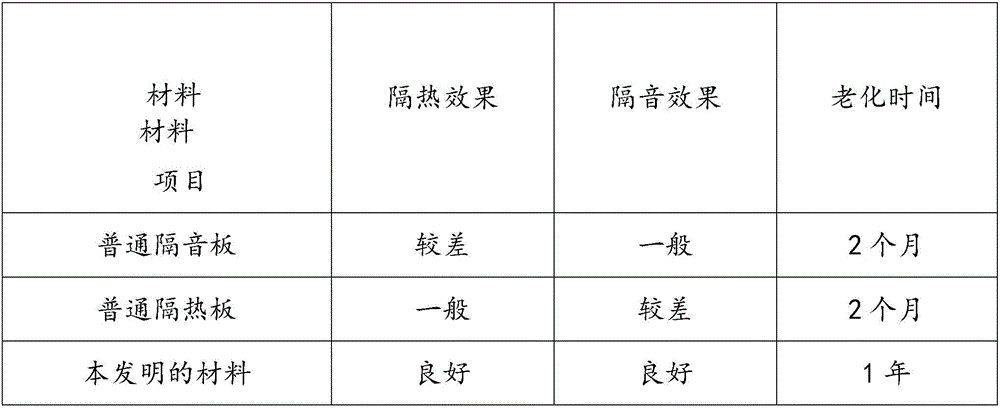

A heat and sound insulation, automobile technology, applied in the field of materials and preparation of automobile heat and sound insulation panels, can solve the problems of inability to resist aging, sound insulation and heat insulation materials, and the service life is not long, so as to achieve long service life and improve The effect of sound insulation and heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A material for an automobile heat and sound insulation panel, which is made of the following materials in parts by weight, including 55 parts of EPDM rubber, 70 parts of epoxy resin, 16 parts of azodicarbonamide, and 4 parts of polystyrene , 8 parts of polyethylene foam, 12 parts of expanded vermiculite, 7 parts of glass fiber, 9 parts of nano-carbon black, 20 parts of nano-alumina, 10 parts of airgel, 7 parts of barium sulfate, 8 parts of polyester, 6 parts of expanded perlite 14 parts of ceramic cotton fiber, 8 parts of aluminum silicate fiber cotton, 2 parts of sodium silicate, 11 parts of dichlorodifluoromethane and 16 parts of fatty alcohol polyoxyethylene ether sodium sulfate.

[0020] A method for preparing a material for an automobile heat-insulating and sound-insulating panel, comprising the following steps:

[0021] 1) Mix 55 parts of EPDM rubber, 70 parts of epoxy resin, 16 parts of azodicarbonamide, 4 parts of polystyrene, 8 parts of polyethylene foam, 12 pa...

Embodiment 2

[0027] A material for automobile heat insulation and sound insulation panels, which is made of the following materials in parts by weight, including 60 parts of EPDM rubber, 72.5 parts of epoxy resin, 17 parts of azodicarbonamide, and 5.5 parts of polystyrene , 11.5 parts of polyethylene foam, 13 parts of expanded vermiculite, 9 parts of glass fiber, 12 parts of nano-carbon black, 21 parts of nano-alumina, 12 parts of airgel, 9.5 parts of barium sulfate, 11 parts of polyester, and 8 parts of expanded perlite 16 parts of ceramic cotton fiber, 9 parts of aluminum silicate fiber cotton, 4 parts of sodium silicate, 12.5 parts of dichlorodifluoromethane and 17 parts of fatty alcohol polyoxyethylene ether sodium sulfate.

[0028] A method for preparing a material for an automobile heat-insulating and sound-insulating panel, comprising the following steps:

[0029] 1) 60 parts of EPDM rubber, 72.5 parts of epoxy resin, 17 parts of azodicarbonamide, 5.5 parts of polystyrene, 11.5 part...

Embodiment 3

[0035] A material for an automobile heat-insulating and sound-insulating panel, which is made of the following materials in parts by weight, including 65 parts of EPDM rubber, 75 parts of epoxy resin, 18 parts of azodicarbonamide, and 7 parts of polystyrene , 15 parts of polyethylene foam, 14 parts of expanded vermiculite, 11 parts of glass fiber, 15 parts of nano-carbon black, 22 parts of nano-alumina, 14 parts of airgel, 12 parts of barium sulfate, 14 parts of polyester, 10 parts of expanded perlite 18 parts of ceramic cotton fiber, 10 parts of aluminum silicate fiber cotton, 6 parts of sodium silicate, 14 parts of dichlorodifluoromethane and 18 parts of fatty alcohol polyoxyethylene ether sodium sulfate.

[0036] A method for preparing a material for an automobile heat-insulating and sound-insulating panel, comprising the following steps:

[0037] 1) Mix 65 parts of EPDM rubber, 75 parts of epoxy resin, 18 parts of azodicarbonamide, 7 parts of polystyrene, 15 parts of polye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com