Preparation method of polyether ketone ketone fine powder for coating

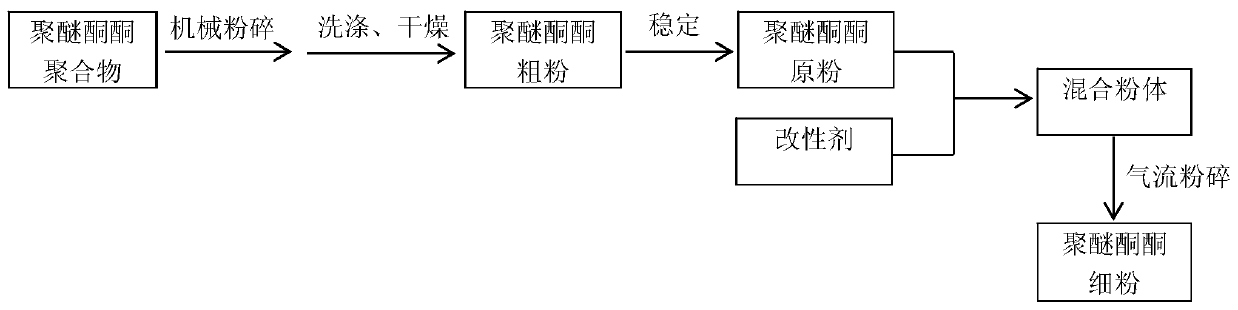

The technology of coarse polyetherketone ketone powder and polyetherketoneketone ketone is applied in the field of preparation of polyetherketoneketone ketone fine powder for coating, and can solve the problems of crushing hammer wear, high local temperature, affecting product index, performance and application range, etc. , to achieve the effect of improving crushing efficiency, eliminating particle edges and corners, and improving melting stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

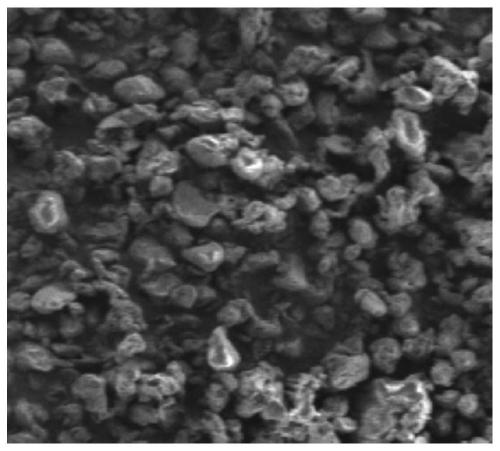

[0029] Polyether ketone ketone is synthesized from diphenyl ether, terephthaloyl chloride (T) and isophthaloyl chloride (I) through Friedel-Crafts reaction. The molar ratio of T:1 in the product is 60:40. The polyether ketone ketone polymer is slowly added to a pipeline high-shear emulsifier for pulverization, and then washed and dried to obtain a polyether ketone ketone coarse powder. The particle size of the coarse powder is 0.1-3 mm. Take 100 kg of polyether ketone ketone coarse powder, and spray a mixed solution of concentrated hydrochloric acid (mass concentration of 31%) and ethanol, totaling 0.5 kg, on its surface. The mass ratio of concentrated hydrochloric acid to ethanol is 1:1. Keep it under vacuum conditions of 180℃ and 0.095MPa for 6 hours, then add 0.5kg of aluminum hydroxide powder with a particle size of D50 of 98μm, pulverize with a jet mill to obtain 93kg of polyetherketone ketone fine powder, which is measured by a laser particle size analyzer. 148μm.

[0030]...

Embodiment 2

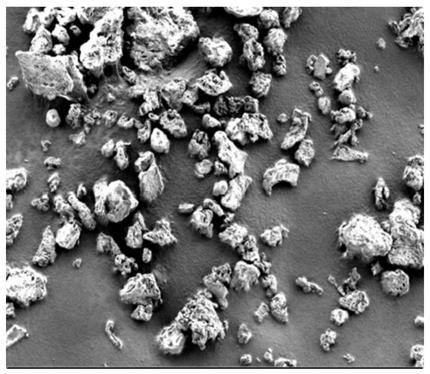

[0035] The polyether ketone ketone polymer obtained in Example 1 is slowly added to an in-line high-shear emulsifier for pulverization, and then washed and dried to obtain a coarse polyether ketone ketone powder with a particle size of 0.1-3 mm. Take 100 kg of polyether ketone ketone coarse powder, and evenly spray the mixed solution of concentrated hydrochloric acid (mass concentration of 33%) and ethanol on its surface, totaling 2 kg. The mass ratio of concentrated hydrochloric acid to ethanol is 1:5. ℃, 0.096MPa vacuum conditions for 2 hours, then add 3kg of silica powder with a particle size of D50 of 85μm, pulverized by a jet mill to obtain 95kg of polyetherketone ketone fine powder, D50 of 55μm measured by a laser particle size analyzer, Under the scanning electron microscope, the edges of the particles have no edges and corners, and the shape is approximately spherical. After electrostatic spraying, the surface of the coating is smooth and defect-free. See the photo of t...

Embodiment 3

[0037] The polyether ketone ketone polymer obtained in Example 1 is slowly added to an in-line high-shear emulsifier for pulverization, and then washed and dried to obtain a coarse polyether ketone ketone powder with a particle size of 0.1-3 mm. Take 100 kg of polyether ketone ketone coarse powder, and evenly spray a mixed solution of concentrated hydrochloric acid (mass concentration of 36%) and ethanol on its surface, totaling 5 kg. The mass ratio of concentrated hydrochloric acid to ethanol is 1:10. ℃, 0.098MPa vacuum conditions for 3 hours, and then add 4kg of diamond powder with a particle size of D50 of 10μm, pulverized by a jet mill to obtain 94kg of polyetherketone ketone fine powder, D50 of 10μm measured by the laser particle size analyzer, in the scanning electron microscope Observe that the edges of the particles have no edges and corners, and the morphology is approximately spherical. After electrostatic spraying, the surface of the coating is smooth and defect-free...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com