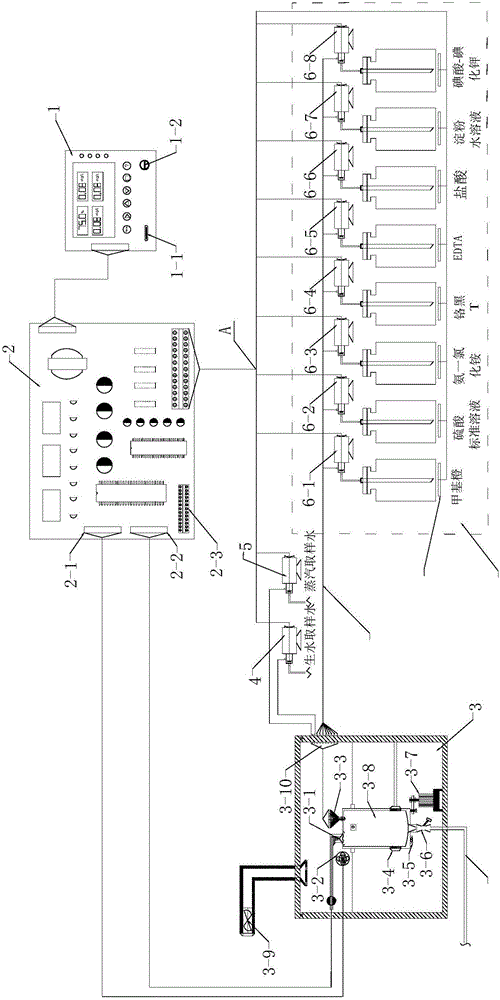

Device and method for automatically detecting water quality of oilfield wet steam generator

A technology of wet steam generator and automatic detection device, which is applied in the direction of chemical analysis by titration method, etc., which can solve the problems of serious fouling, lagging test time, and explosion hazard of hydrogen sulfide gas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

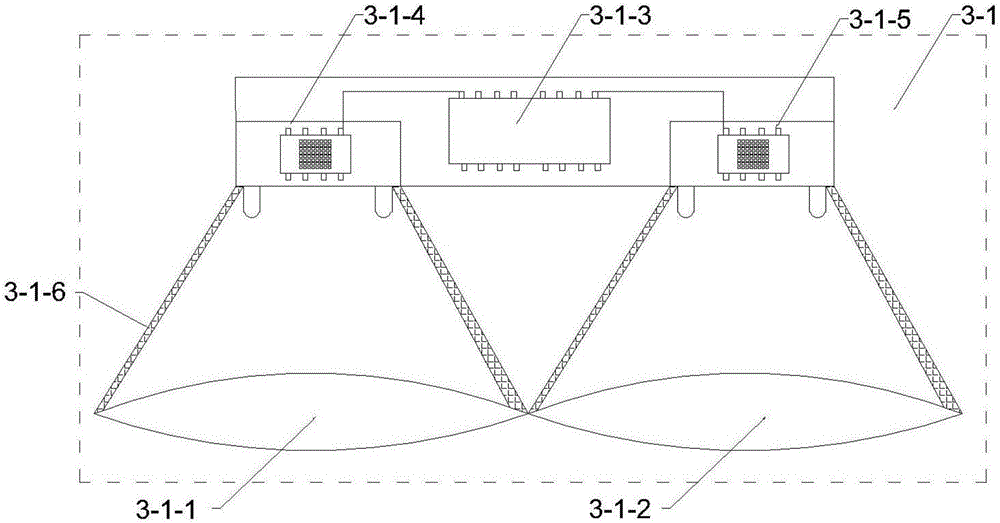

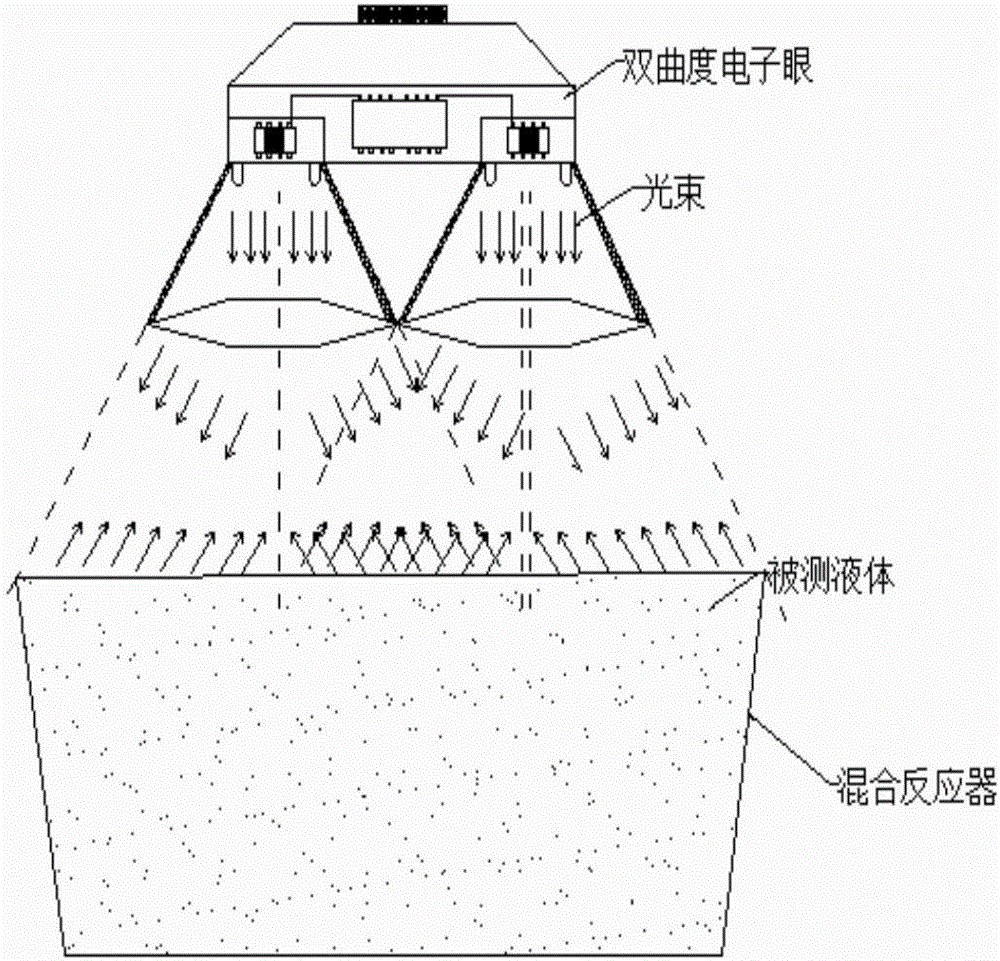

[0110] In this embodiment, the light intensity emitted by the hyperbolic electronic eye during work is 150 lumens;

[0111] Before the water quality test, the standard curves of color and color saturation change for hardness test, wet steam dryness test and excess sodium sulfite test are respectively generated. The generation process of each standard curve is as follows:

[0112] In the hardness test, the generation process of the standard curve of color and color saturation change is as follows: take the sampled water with known hardness value as the standard water sample, add it to the mixing reactor, start the hardness test function of the device, extract the ammonia-ammonium chloride buffer solution, Continuously drop into the mixing reactor, then extract the chrome black T indicator, continuously drop into the mixing reactor, fully mix with the sampling water, and continuously drop into the EDTA standard solution according to the predetermined amount, the double curvature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com