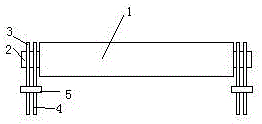

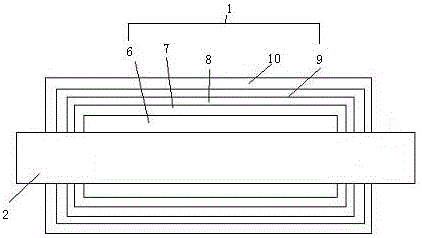

Equipotential shielding tubular high-current bus and preparation method therefor

A technology of tubular busbar and shielding tube, which is applied to power cables with shielding/conducting layers, cable/conductor manufacturing, circuits, etc. environment, reduce busbar loss, and improve the effect of absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The preparation method of the equipotential shielding tube type high current busbar is as follows:

[0019] ①Wrap a layer of wave-transparent layer evenly outside the tubular busbar, the thickness of the wave-transparent layer is 0.02mm, the raw material used in the wave-transparent layer is glass fiber, put the glass fiber into the cable forming machine and react for 10min, the The temperature of the cable forming machine is 195°C;

[0020] ② Evenly wrap a layer of equipotential shielding layer outside the wave-transmitting layer. The thickness of the equipotential shielding layer is 0.01mm. The equipotential shielding layer is made of silicone rubber, and a small amount of white carbon black, diisoperoxide Prepared from propylbenzene and stearic acid, silicone rubber, white carbon black, dicumyl peroxide and stearic acid are put into a cable forming machine to react for 5 minutes, and the temperature of the cable forming machine is 175°C;

[0021] 3. Evenly wrap one ...

Embodiment 2

[0026] The preparation method of the equipotential shielding tube type high current busbar is as follows:

[0027] ① Wrap a layer of wave-transparent layer evenly outside the tubular busbar. The thickness of the wave-transparent layer is 0.04mm. The raw material used in the wave-transparent layer is glass fiber, and the glass fiber is put into the cable forming machine to react for 15 minutes. The temperature of the cable forming machine is 215°C;

[0028] ② Evenly wrap a layer of equipotential shielding layer outside the wave-transmitting layer. The thickness of the equipotential shielding layer is 0.02mm. The equipotential shielding layer is made of silicone rubber, and a small amount of white carbon black, diisoperoxide Prepared from propylbenzene and stearic acid, silicone rubber, white carbon black, dicumyl peroxide and stearic acid are put into a cable forming machine to react for 8 minutes, and the temperature of the cable forming machine is 200°C;

[0029] 3. Evenly w...

Embodiment 3

[0034] The preparation method of the equipotential shielding tube type high current busbar is as follows:

[0035] ① Wrap a layer of wave-transparent layer evenly outside the tubular busbar, the thickness of the wave-transparent layer is 0.05mm, the raw material used in the wave-transparent layer is glass fiber, put the glass fiber into the cable forming machine and react for 20min, the The temperature of the cable forming machine is 225°C;

[0036] ② Evenly wrap a layer of equipotential shielding layer outside the wave-transmitting layer. The thickness of the equipotential shielding layer is 0.03mm. The equipotential shielding layer is made of silicone rubber, and a small amount of white carbon black, diisoperoxide Prepared from propylbenzene and stearic acid, silicone rubber, white carbon black, dicumyl peroxide and stearic acid are put into a cable forming machine to react for 10 minutes, and the temperature of the cable forming machine is 215°C;

[0037] 3. Evenly wrap on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com