Membrane protecting coating for preventing dendrite short circuit of metal negative electrode and preparation method thereof

A protective coating and diaphragm technology, applied in the direction of circuits, electrical components, battery pack components, etc., can solve problems such as metal negative electrode short circuit, achieve the effect of preventing battery short circuit, reducing battery polarization, and maintaining energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

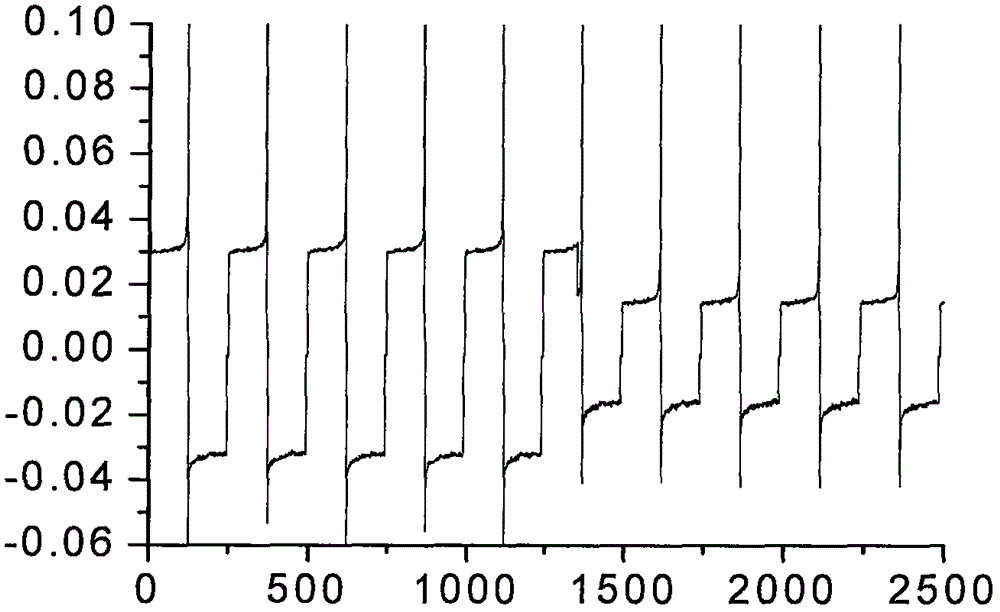

Embodiment 1

[0036] Lithium polyacrylate (molecular weight: 10,000), a binder capable of chelating and adsorbing lithium ions, is mixed with acetylene black at a mass ratio of 80:20, then an organic solvent-N-methylpyrrolidone is added, stirred and mixed in a vacuum to prepare a slurry . The length and width are respectively 100mm and 50mm polypropylene celgard diaphragm (0.02mm) on the coating machine, the above-mentioned slurry is coated on the diaphragm surface, the thickness of the coating is controlled at 120um, then placed in a vacuum oven for 60 ℃ vacuum to remove the solvent and dry for 12h. Using the diaphragm covered with a lithium polyacrylate-carbon protective layer on one side, a Cu-Li half-cell is assembled with a metal lithium negative electrode on a copper foil, and the electrolyte is a solution of lithium hexafluorophosphate, ethylene carbonate, and diethyl carbonate. The test current is 0.31mA cm -2 , after 400 lithium deposition-dissolution cycles, a large number of de...

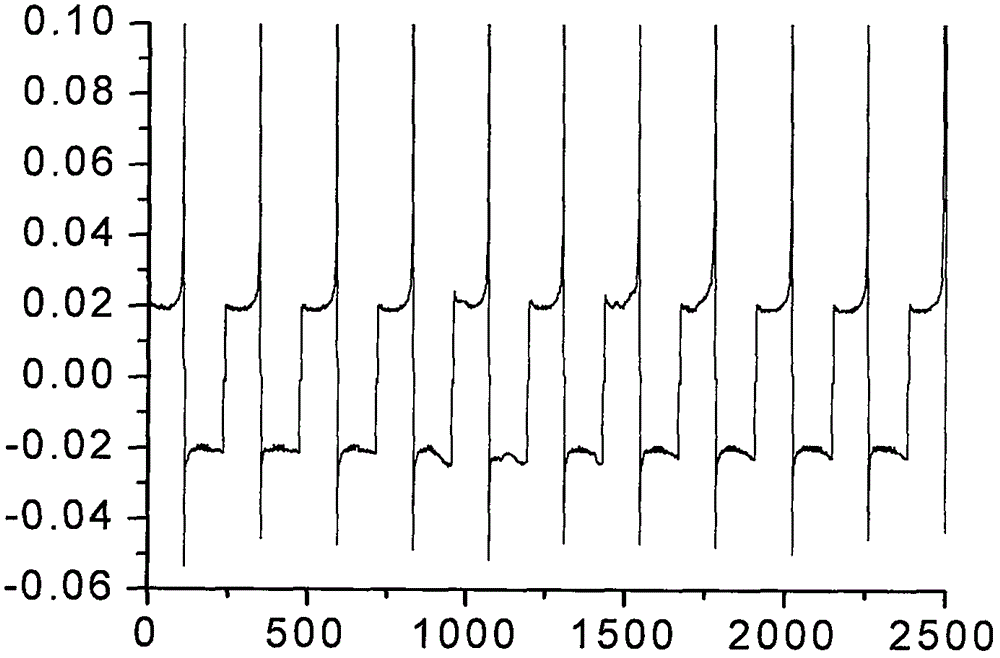

Embodiment 2

[0038]Add 55% binder polyacrylic acid lithium (molecular weight 10000) in the polyaminophosphonic acid resin that has chelation and adsorption to lithium ions but does not have adhesion, then add organic solvent-N-methylformamide, vacuum Stir to mix to make a slurry. Spread the polypropylene celgard membrane (0.02mm) with a length and width of 80mm and 60mm on the coating machine, and coat the above-mentioned slurry on the surface of the membrane. The thickness of the coating is controlled at 130um, and then placed in a vacuum of 0.1 Remove the solvent and dry in an MPa vacuum oven at 60° C. for 12 hours. Using the diaphragm covered with polyacrylate lithium-chelating resin inert protective coating on one side, a Cu-Li half-cell is assembled with metal lithium negative electrode and copper foil, and the electrolyte is lithium hexafluorophosphate, ethylene carbonate, and diethyl carbonate solution. The test current is 0.31mA cm -2 , after 500 lithium deposition-dissolution cy...

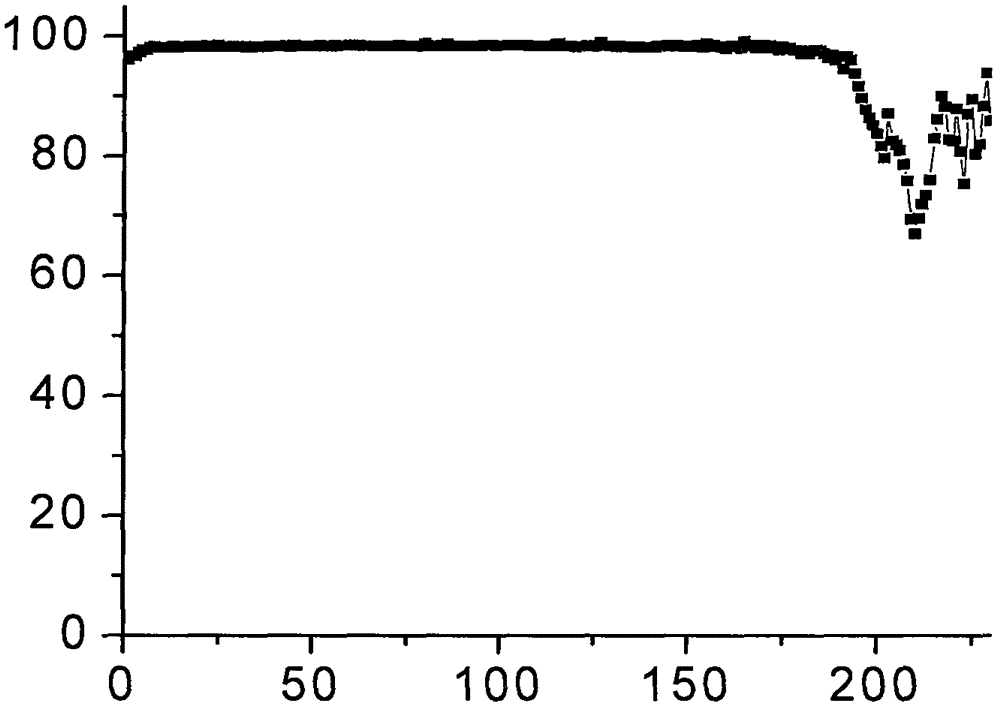

Embodiment 3

[0040] Add 30% binder lithium polyacrylate (molecular weight: 10000) into the non-adhesive chelating resin zinc polyacrylate, then add water and ethanol mixed solvent, and vacuum stir and mix to prepare slurry. Use a spray gun to repeatedly spray the above slurry on the glass fiber diaphragm with a length and width of 80mm and 40mm respectively, so that the above slurry completely covers the surface of the glass fiber diaphragm. The thickness of the coating is 80um and placed in a vacuum with a vacuum degree of 0.1MPa. Vacuumize and remove the solvent in an oven at 80°C for 10 h. Spray the other side of the glass fiber diaphragm in the same way, and dry it in vacuum for 10 hours. The thickness of the coating is 80um. The diaphragm covered with polyacrylic acid zinc protective layer on both sides is adopted, a Cu-Zn half cell is assembled with metal zinc negative electrode and copper foil, and the electrolyte solution is lithium sulfate and zinc sulfate aqueous solution. The t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com