Low-temperature salt catalytic synthesis method of phosphorite structure lanthanum germinate powder material

A technology of powder material and synthesis method, applied in structural parts, fuel cells, electrochemical generators and other directions, to achieve the effects of good crystal morphology, low energy consumption and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Use lanthanum oxide and germanium oxide as the reaction raw materials, the molar mass ratio is 9.33:12, and lithium chloride is used as the catalyst. The mass ratio of LiCl to the initial reaction raw materials is 2:1. dehydrated ethanol; the mixture is ball-milled with a star ball mill, the mixture after ball milling is poured into a 500ml beaker, and put into an oven for drying at a temperature of 100°C for 24 hours; the mixture after drying Put it into a vertical tube furnace with a crucible, and sinter at 500°C for 6 hours; use the self-assembled washing device to wash off the lithium chloride in the powder with deionized water, and the washing liquid Titration detection with silver nitrate solution, after confirming that there is no white flocculent precipitate, continue to wash twice; put the washed powder into a 250ml beaker, and dry it in a drying oven at 100°C for 24 hours to obtain the expected product.

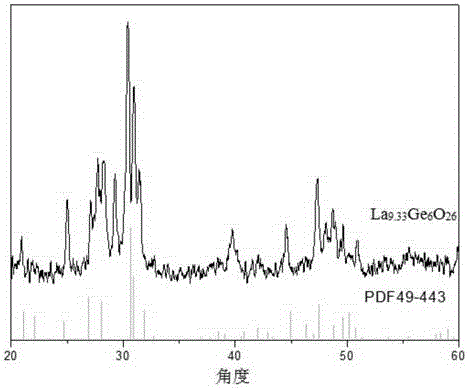

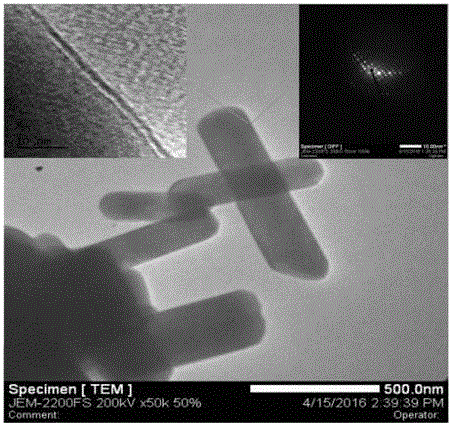

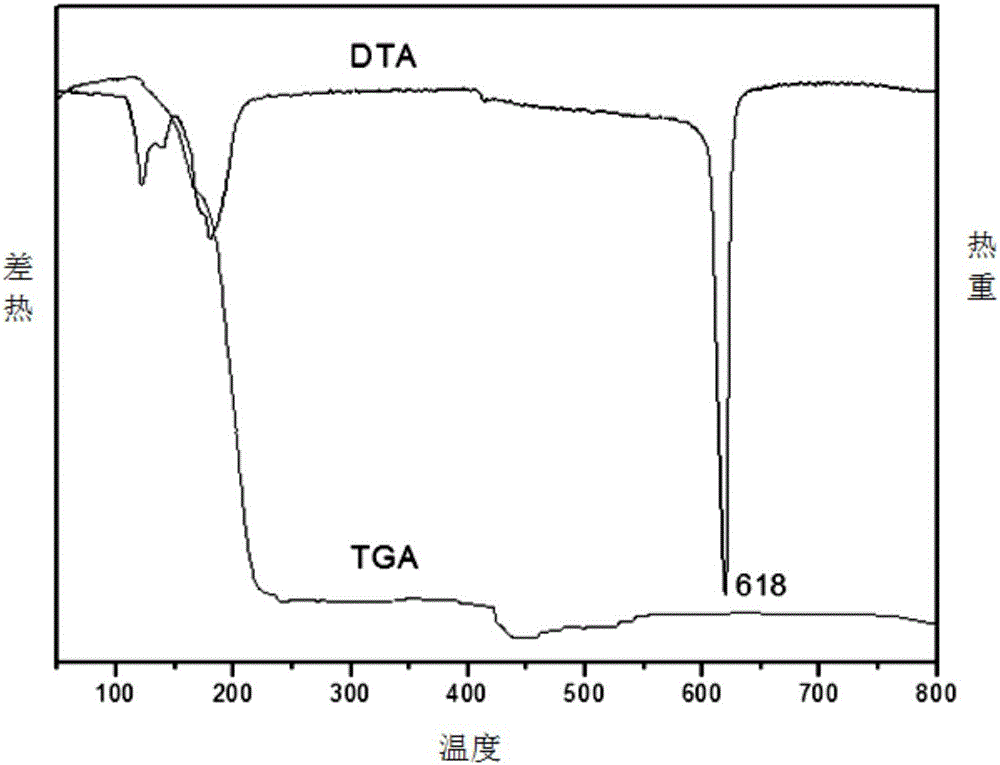

[0031] figure 2 with image 3 Given the original mix...

Embodiment 2

[0033] Use lanthanum oxide and germanium oxide as the reaction raw materials, the molar ratio is 9.33:12, and lithium chloride is used as the catalyst. The mass ratio of LiCl to the initial reaction raw materials is 2:1. Anhydrous ethanol; the mixture is ball-milled with a star ball mill, the mixture after ball milling is poured into a 500ml beaker, and put into an oven for drying, the drying temperature is 100°C, and the time is 24 hours; the dried mixture is used The crucible was loaded into a vertical tube furnace and sintered at 550°C for 6 hours; the sintered powder was washed off the lithium chloride in the powder with deionized water using a self-assembled washing device, and the washing liquid was washed with Titration detection of silver nitrate solution, after confirming that there is no white flocculent precipitate, continue to wash twice; put the washed powder into a 250ml beaker, and dry it in a drying oven at 100°C for 24 hours to obtain the expected product.

[...

Embodiment 3

[0036] Use lanthanum oxide and germanium oxide as the reaction raw materials, the molar ratio is 9.33:12, and lithium chloride is used as the catalyst. The mass ratio of LiCl to the initial reaction raw materials is 2:1. Anhydrous ethanol; the mixture is ball-milled with a star ball mill, the mixture after ball milling is poured into a 500ml beaker, and put into an oven for drying, the drying temperature is 100°C, and the time is 24 hours; the dried mixture is used The crucible was loaded into a vertical tube furnace and sintered at 600°C for 6 hours; the sintered powder was washed off the lithium chloride in the powder with deionized water using a self-assembled washing device, and the washing liquid was washed with Titration detection of silver nitrate solution, after confirming that there is no white flocculent precipitate, continue to wash twice; put the washed powder into a 250ml beaker, and dry it in a drying oven at 100°C for 24 hours to obtain the expected product.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com