Discharge plasma generation device for industrial waste gas treatment

A discharge plasma and industrial waste gas technology, applied in the direction of plasma, electrical components, separation methods, etc., can solve the problems of complex electrode structure, inconvenient maintenance, etc., and achieve the effect of increasing the space volume, increasing the treatment effect, and extending the space volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A discharge plasma generating device for industrial waste gas treatment will be introduced below in conjunction with an embodiment.

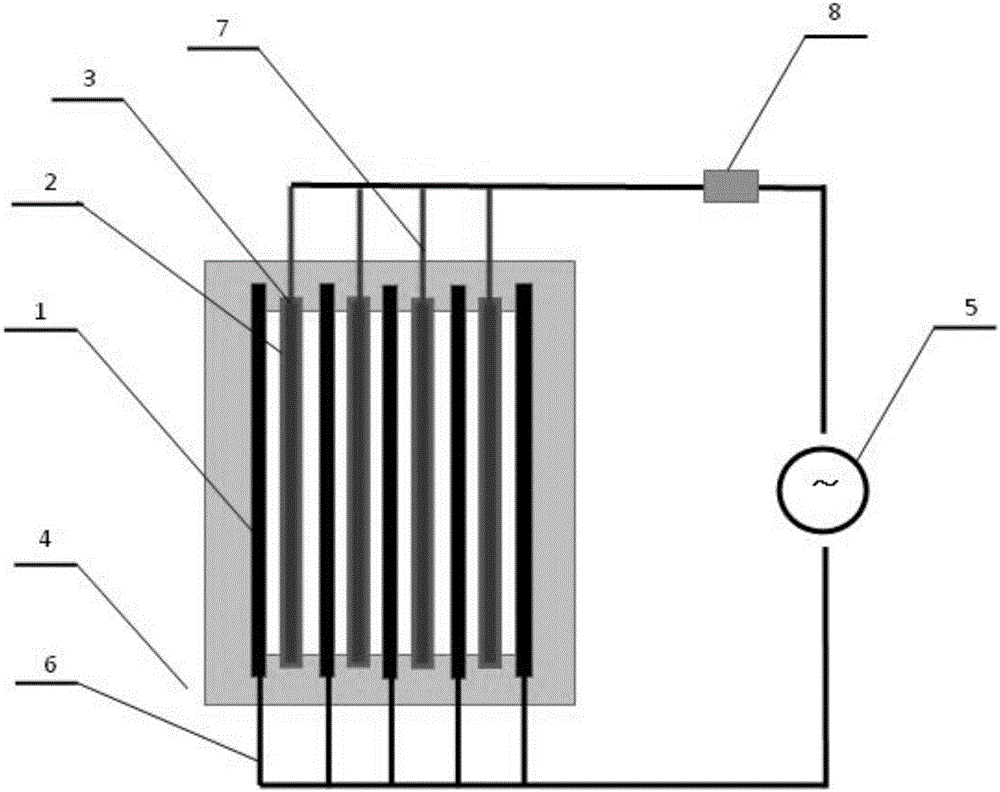

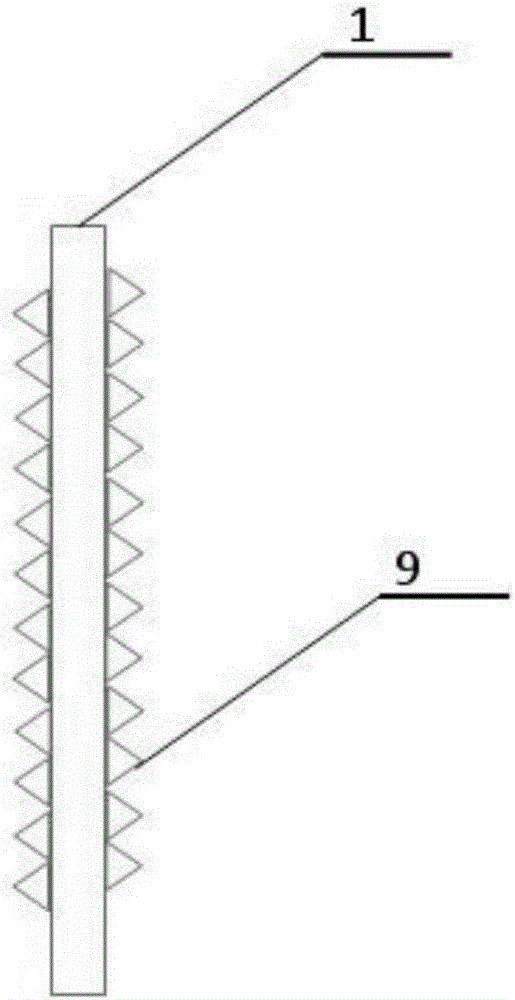

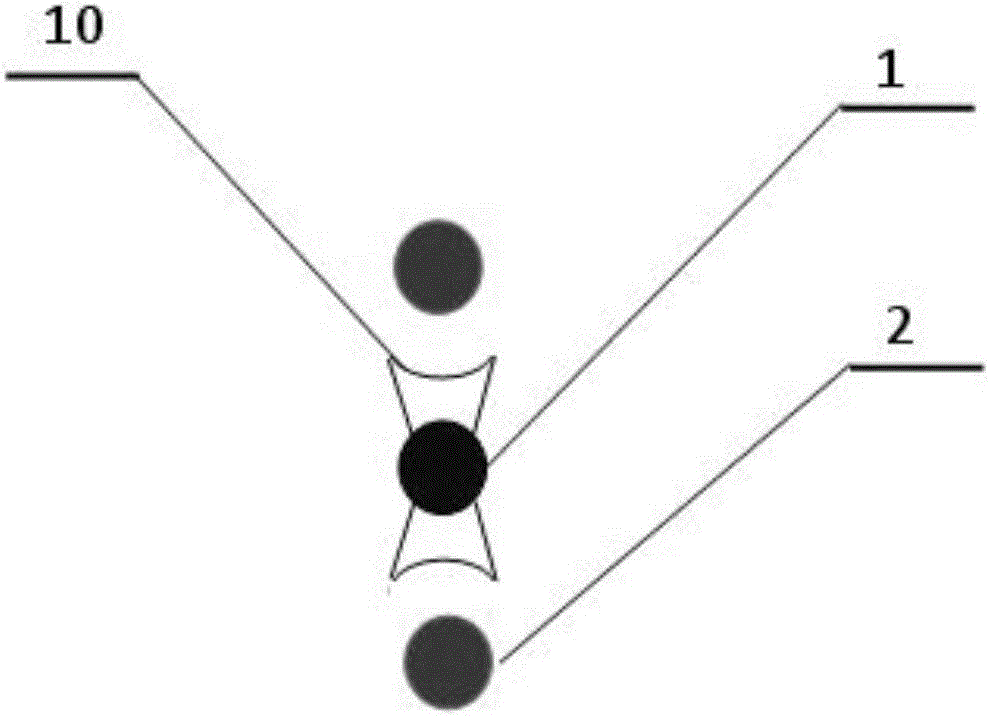

[0025] Such as figure 1 Shown is a schematic diagram of a discharge plasma generator for industrial waste gas treatment. The discharge plasma electrode structure is composed of 5 metal threaded rod electrodes 1, 4 insulating dielectric tubes 2, the inner conductor 3 of the insulating dielectric tube and the insulator frame 4 and other components. Metal threaded rod electrode 1 such as figure 2 As shown, it is a stainless steel threaded rod with a diameter of 10mm ± 0.1mm, a length of 500mm, a pitch of 2mm, and a thread depth of 1.5mm. It is connected as an electrode terminal 6 through a wire with an insulating layer. The insulating dielectric tube 2 is a quartz glass tube with an outer diameter of 10 mm ± 0.1 mm, an inner diameter of 7 mm ± 0.1 mm, and a length of 600 mm; the inner conductor 3 of the insulating dielectric tube is a sod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com