Anti-tartar toothpaste and preparation method thereof

An anti-tartar toothpaste and gelatin technology, applied in the field of oral care, can solve the problems of poor stability of peroxides, poor taste of toothpaste, corrosion of tooth enamel, etc., achieve the best suspension, reduce adsorption, and promote remineralization effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

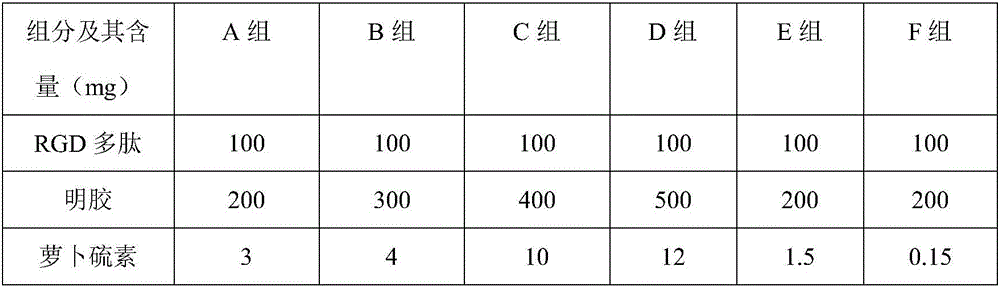

[0035]Embodiment 1 The preparation of intercalation and RGD polypeptide-gelatin nanoparticles

[0036]

[0037] Preparation of group A embedding and RGD polypeptide-gelatin nanoparticles:

[0038] (1) Weigh 200mg gelatin and dissolve it in 100mL water to make a gelatin solution with a concentration of 2mg / mL; weigh 100mg RGD polypeptide and dissolve it in 100mL water to make a concentration of 1mg / mL RGD polypeptide solution;

[0039] (2) Pass the gelatin solution and the RGD polypeptide solution prepared in step (1) through a 0.22 μm filter respectively, and set aside;

[0040] (3) Slowly add 3mg sulforaphane dropwise to 100mL gelatin solution, magnetically stir for 10min, then dropwise add sodium tripolyphosphate solution, the final concentration of described sodium tripolyphosphate in the solution is 4% (m / v), Continue magnetic stirring for 15 minutes, finally add 100 mL of RGD polypeptide solution, vortex for 8 minutes, centrifuge the liquid at 20,000 rpm for 30 minute...

Embodiment 2

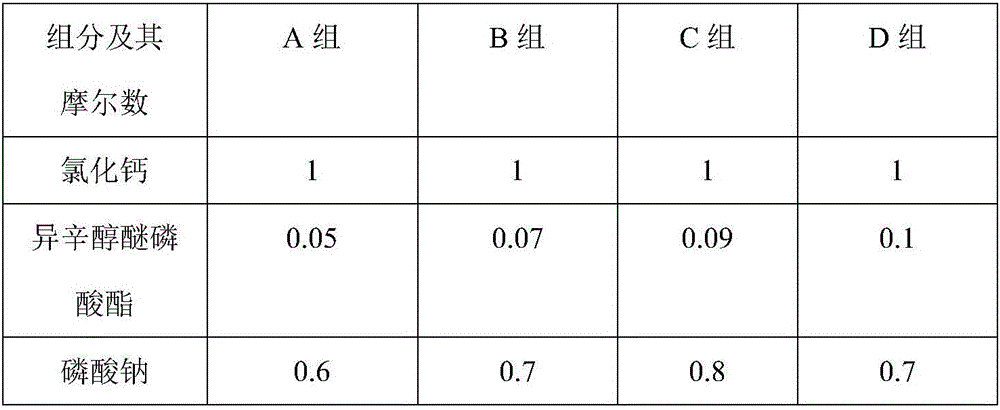

[0042] The preparation of embodiment 2 amorphous calcium phosphate microspheres

[0043]

[0044] Preparation of group A amorphous calcium phosphate microspheres:

[0045] (1) Dissolve calcium chloride in water to make an aqueous calcium chloride solution, then add isooctyl ether phosphate to the calcium chloride aqueous solution, stir until the material is completely dissolved, and the isooctyl ether phosphate and chloride The molar ratio of calcium is 0.05:1;

[0046] (2) Dissolve sodium phosphate in water to make an aqueous solution of sodium phosphate, then add dropwise to the solution prepared in step (1), the mol ratio of the sodium phosphate to calcium chloride is 0.6:1, stir evenly, and then Add polylactic acid with a final concentration of 8% (m / v), conduct a microwave-assisted hydrothermal reaction at 100°C for 45 minutes, cool to room temperature, and centrifuge to collect the precipitate;

[0047] (3) The precipitate obtained in step (2) was washed 3 times wit...

Embodiment 3-6

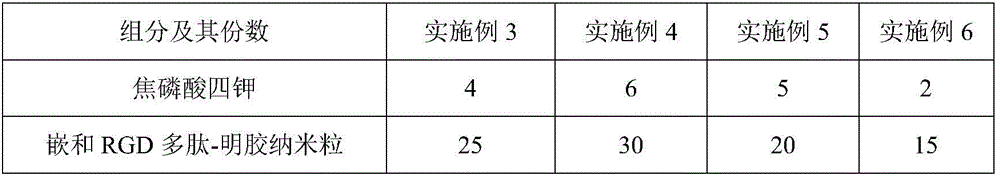

[0050] The preparation of embodiment 3-6 antitartar toothpaste

[0051] The intercalated RGD polypeptide-gelatin nanoparticles in the anti-tartar toothpaste raw materials of Examples 3-6 of the present invention were obtained from Group A of Example 1; the amorphous calcium phosphate microspheres were prepared from Group D of Example 2. The composition and content thereof of each embodiment anti-tartar are shown in the table below:

[0052]

[0053]

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com