Acceleration sensor and manufacturing method thereof

An acceleration sensor, axial acceleration technology, applied in the measurement of acceleration, speed/acceleration/shock measurement, manufacturing tools, etc., can solve the problem of low sensitivity, achieve the effect of improving sensitivity, reducing parasitic capacitance, and widening the operating temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

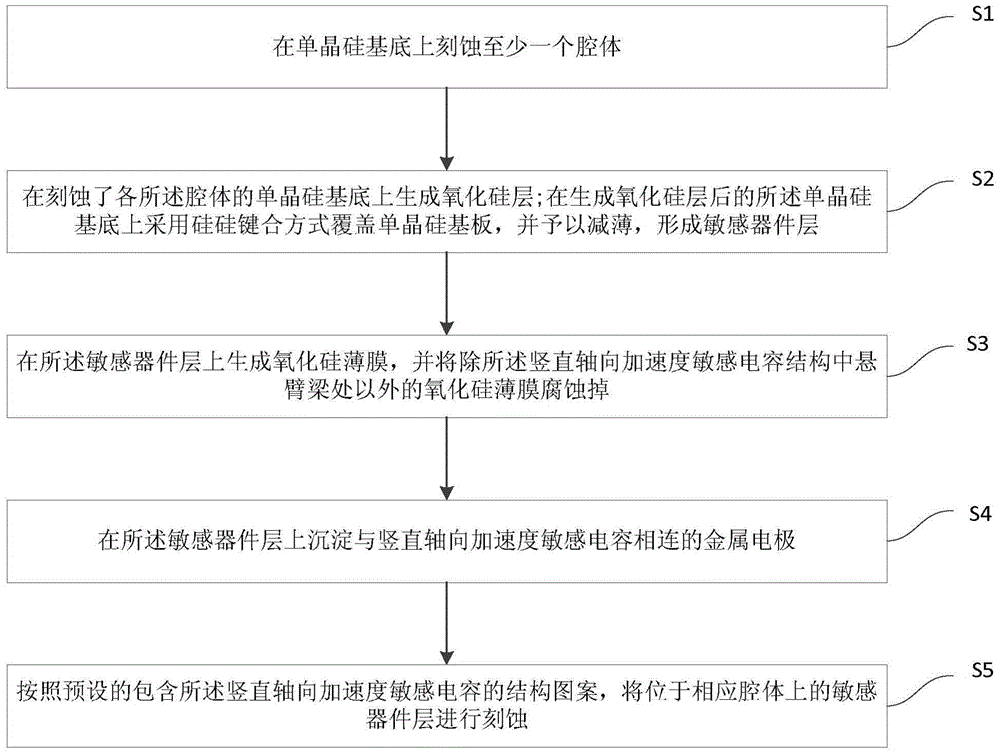

[0034] figure 1 A method of manufacturing an acceleration sensor according to an aspect of the present application is shown. The manufacturing method can be used to manufacture sensors that only measure z-axis acceleration, and can also be used to manufacture sensors that measure three-axis axial acceleration.

[0035] In step S1, at least one cavity is etched on the single crystal silicon substrate; wherein, the cavity includes: a first cavity providing a movement space for a vertical acceleration sensitive capacitor.

[0036] Here, the method of etching at least one cavity on the single crystal silicon substrate can be first coated with photoresist on the single crystal silicon substrate, and then according to the preset cavity position pattern, the photoresist is etched performing photolithography exposure processing and etching processing all cavities including the first cavity.

[0037] Alternatively, the manner of etching at least one cavity on the single crystal silic...

Embodiment 2

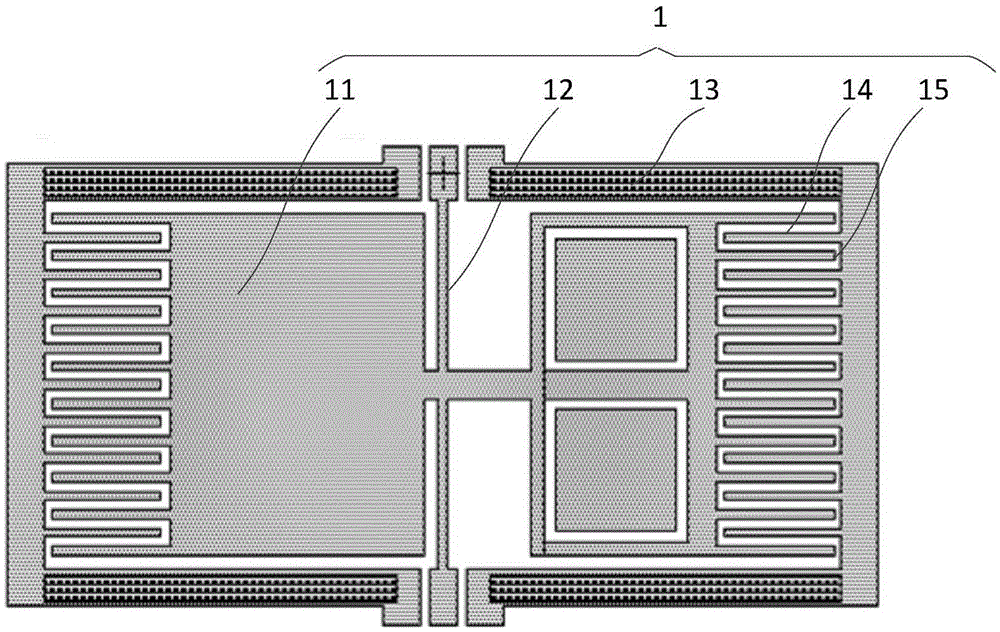

[0061] The difference from step S1 in Embodiment 1 is that each cavity containing the stopper is etched on the single crystal silicon substrate; wherein, the stopper in the first cavity is located at the first mass The first mass block corresponding to the pattern 11 is located at a position with a lighter mass on one side of the torsion beam corresponding to the torsion beam pattern 12 .

[0062] For example, in the structural pattern of the vertical axial acceleration sensitive capacitor, the torsion beam pattern 12 bisects the first mass block pattern 11, and the part corresponding to the lighter mass in the first mass block pattern 11 contains a hollow area, the The stop portion in the first cavity is provided corresponding to the hollow area.

[0063]The difference from step S2 in Embodiment 1 is that during the etching of the sensitive device layer on the corresponding cavity according to the preset structural pattern including the vertical axial acceleration sensitive c...

Embodiment 3

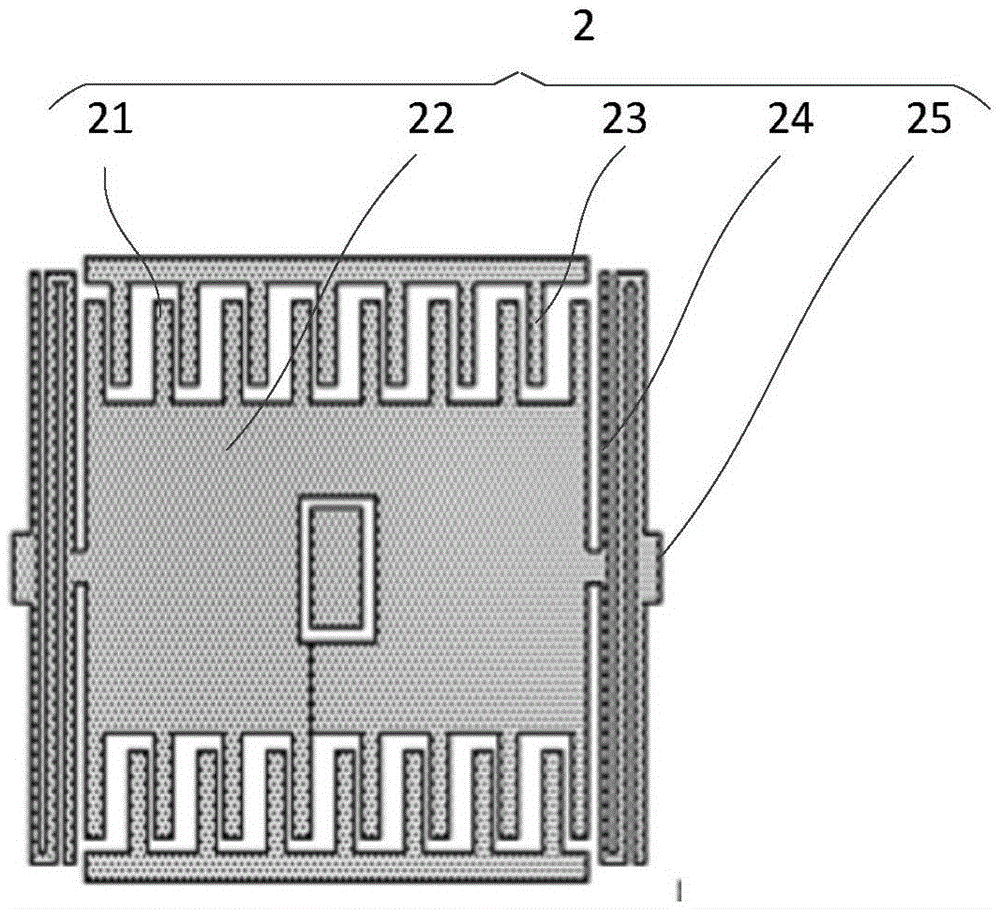

[0067] Such as Figure 4 , 7 As shown in and 8, another embodiment of the present invention is an acceleration sensor manufactured according to the above manufacturing method.

[0068] The acceleration sensor may be a sensor that only measures vertical (z-axis) acceleration, or a sensor that includes three-axis axial acceleration.

[0069] The acceleration sensor includes: a single crystal silicon substrate 100 , a sensitive device layer 500 , a silicon oxide film 408 and a metal electrode 200 .

[0070] The single crystal silicon substrate 100 includes at least one cavity, wherein the cavity includes: a first cavity 102 providing a space for a vertical acceleration sensitive capacitor.

[0071] Here, the number of cavities is related to the direction of acceleration that the acceleration sensor can sense. If the sensor is a z-axis acceleration sensor, it may only include the first cavity 102 . If the sensor is a three-axis acceleration sensor, the cavity includes the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com