A kind of preparation method of PBO fiber composite material

A fiber composite material and fiber technology, which is applied in the field of composite material preparation, can solve problems such as unsatisfactory effect, reinforced fiber and resin matrix interface force, etc., to avoid loss, improve wettability and adhesion, and improve ILSS. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

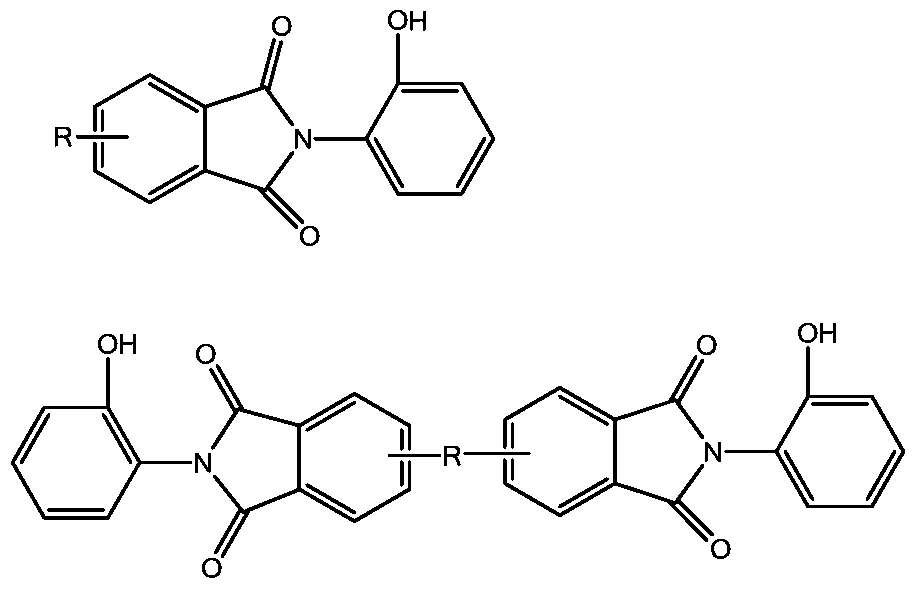

[0031] 1. Add 0.1 mole of phthalic anhydride, 0.13 mole of 2-aminophenol and 130ml of glacial acetic acid into a three-necked flask equipped with a stirring bar, a thermometer, and a condensing reflux device, mix and heat up and reflux for 6 hours. After the reaction, the reaction solution was cooled to room temperature. After the precipitate was completely separated out, it was filtered, washed and precipitated with 350 ml of methanol to remove unreacted raw materials. The final product was dried in a vacuum oven at 70°C for 12 hours. Product 1 was obtained as a white solid powder.

[0032] 2. After fully mixing 0.1 mole of product 1, 0.13 mole of aniline, 0.12 mole of paraformaldehyde and 30 ml of xylene, raise the temperature to 120°C and stir for 6 hours. After the reaction, the reaction liquid was poured out into the beaker, the unreacted raw materials were washed and removed, and the temperature was slowly lowered in the fume hood for recrystallization. After filtrati...

Embodiment 2

[0040] In this example, only the aromatic amine in the second step is different from Example 1, and thus the charging ratio in Step 2 is also different, and the rest are the same as Example 1.

[0041] In step 2, the feed ratio is: 0.1 mole of product 1, 0.6 mole of aromatic amine, 0.12 mole of paraformaldehyde and 30 ml of xylene.

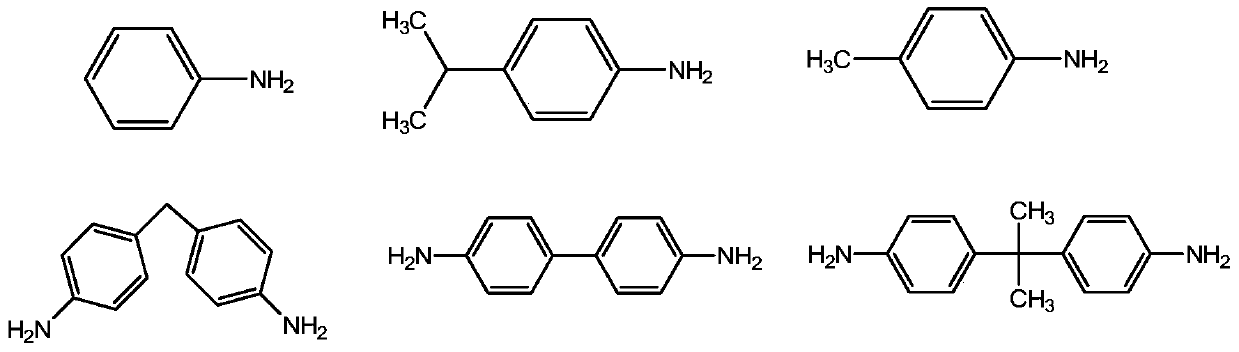

[0042] The chemical structural formula of aromatic amine in the present embodiment is as follows:

[0043]

Embodiment 3

[0045] In this embodiment, only the aromatic acid anhydride in the first step is different from embodiment 1, and the charging ratio in step 1 thus caused is also different, and the rest are the same as embodiment 1.

[0046]In step 1, the feed ratio is: 0.05 mole of aromatic acid anhydride, 0.13 mole of 2-aminophenol and 130 ml of glacial acetic acid.

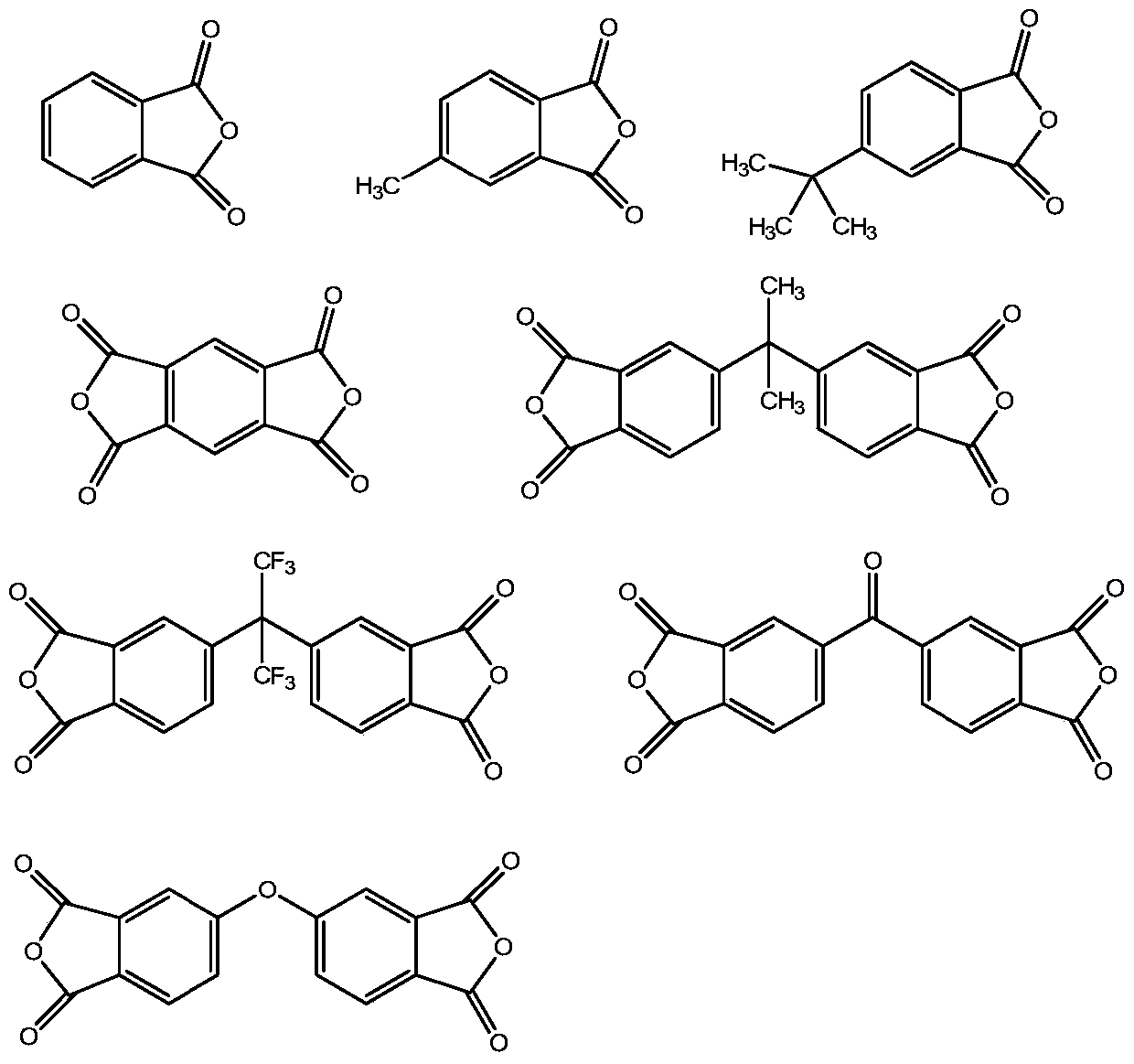

[0047] The chemical structural formula of the aromatic acid anhydride in the present embodiment is as follows:

[0048]

[0049] The advantage of the present invention is that a resin with good compatibility with PBO fibers is introduced into the matrix resin as a mixed resin, which can significantly improve the wettability and adhesion of PBO fibers to the matrix resin, thereby significantly improving the interface properties of the resin and fibers .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com