Anti-corrosion decorative panel

A decorative panel and corrosion-resistant technology, applied in the direction of anti-corrosion coatings, coatings, layered products, etc., can solve the problems of high production cost, low strength, pollution of the environment, etc., and achieve the effect of high strength and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

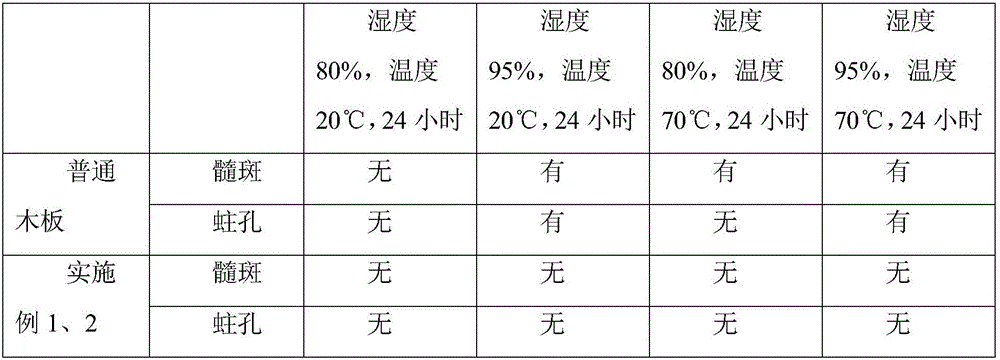

Examples

Embodiment 1

[0024] 1. Dry nylon 6 and lithium chloride in an oven until the water content is less than 0.1%, ball-mill lithium chloride in a ball mill, and pass through a 100-mesh sieve. The parts by weight of the following components are: Nylon 6: 95 parts; Lithium chloride: 5 parts. The two were mixed in an internal mixer for 5 minutes, and the temperature was set at 240 ° C. After mixing, the low melting point nylon 6 was crushed in the crusher.

[0025] 2. The weight fractions of the following components are: low melting point nylon 6:50 parts, wood fiber: 40 parts, isocyanate chain extender: 5 parts, stearic acid: 3 parts, iron oxide red: 2 parts. The above materials are mixed in a mixer and granulated by a granulator, and the granulated material is extruded to obtain a wood-plastic material.

[0026] 3. Add methyl methacrylate, bakelite powder and ethyl acetate into the reaction kettle and stir at a stirring speed of 200 rpm. During stirring, heat up to 150°C, then add ethylene gly...

Embodiment 2

[0029] 1. Dry nylon 66 and calcium chloride in an oven until the moisture content is below 0.1%. After ball milling calcium chloride in a ball mill, pass through a 100-mesh screen. The parts by weight of the following components are: nylon 66 : 85 parts; Lithium chloride: 15 parts. The two were mixed in an internal mixer for 6 minutes, the temperature was set at 260° C., and the mixed low-melting point nylon 66 was crushed in a crusher.

[0030] 2. The weight fractions of the following components are: low melting point nylon 66:80 parts, wood fiber: 15 parts, zinc stearate: 3 parts, iron oxide yellow: 2 parts. The above materials are mixed in a mixer and granulated by a granulator, and the granulated material is injection molded. Get wood-plastic material.

[0031] 3. Add methyl methacrylate, bakelite powder and ethyl acetate into the reaction kettle and stir at a stirring speed of 200 rpm. During stirring, heat up to 150°C, then add ethylene glycol monoethyl ether and limone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com