Inverted organic solar cell adopting phthalocyanine derivative film as cathode buffer layer and preparation method thereof

A cathode buffer layer and solar cell technology, applied in the field of solar cells, can solve the problems of unsuitability for commercialization, environmental pollution, high toxicity of organic solar cell materials, etc., and achieves improvement of overall efficiency, good alcohol solubility, and improvement of incident photoelectron conversion efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

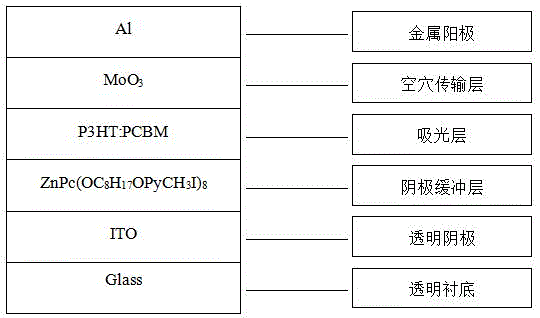

[0037] The etched and cleaned ITO conductive glass was sonicated twice for 15 min with washing solution, deionized water, acetone, and ethanol in turn. Connect P3HT and PC 61 BM was dissolved in dichlorobenzene solution at a mass ratio of 1:1 to prepare a solution with a concentration of 17 mg / ml. The mixed solution was uniformly stirred at a temperature of 60 ° C for 12 hours and was set aside. ZnPc(OC 8 H 17 OPyCH 3 i) 8 The material was dissolved in ethanol solvent (concentration 0.8 mg / ml). Dry the cleaned ITO conductive glass with nitrogen and UV for 15min. Then spin-coated ZnPc(OC 8 H 17 OPyCH 3 i) 8 solution. The process is to first rotate at a low speed of 700r / min for 10s, and then rotate at a high speed of 3000r / min for 60s to form a cathode buffer layer. Then, the evaporated substrate was transferred to a high-quality hand-operated box filled with N2, and the mixed solution of P3HT:PCBM was spin-coated on the cathode buffer layer at 800 rpm for 60 s, and ...

Embodiment 2

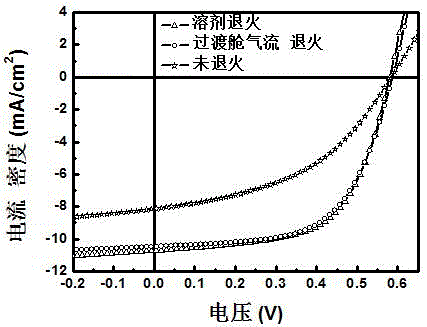

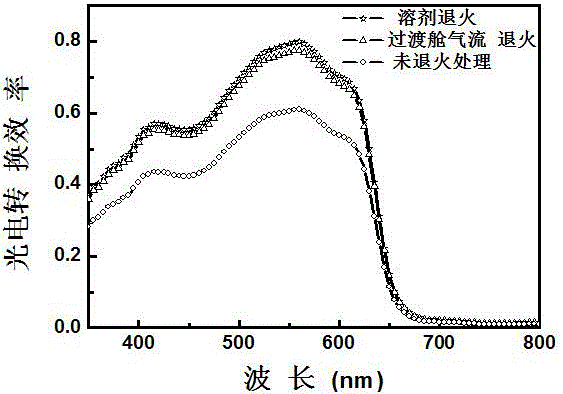

[0039] The inverted organic solar cell was prepared by the same method as in Example 1. The difference from Example 1 is that ZnPc(OC) was spin-coated on ITO in this example. 8 H 17 OPyCH 3 i) 8 after the solution. The substrate was placed in an environment full of ethanol vapor and annealed for 20 min to form a cathode buffer layer. obtained as ZnPc(OC 8 H 17 OPyCH 3 i) 8 High stability inverted organic solar cells as cathode buffer layer. Its device structure see figure 1 , at room temperature, the J-V curve of the device was measured. from figure 2 The effect of solvent vapor annealing on the performance of organic solar cells can be seen. Compared with the unannealed device, the performance of the device after ethanol vapor treatment is significantly improved, and the device performance reaches PCE 3.76%, Voc 0.579V, Jsc 10.71mA / cm 2 , FF 0.61. from image 3 It can be seen that the spectral response wavelength range of the device after solvent annealing is s...

Embodiment 3

[0041] The inverted organic solar cell was prepared by the same method as in Example 1. The difference from Example 1 is that ZnPc(OC) was spin-coated on ITO in this example. 8 H 17 OPyCH 3 i) 8 after the solution. The substrate was placed in the small transition chamber of the Braun glove box, and the device was annealed by the flow of inert gas circulating in the small transition chamber for 20 min in the transition chamber to form a cathode buffer layer. obtained as ZnPc(OC 8 H 17 OPyCH 3 i) 8 High stability inverted organic solar cells as cathode buffer layer. At room temperature, the J-V curve of the device was measured (see figure 2 ). from figure 2 It can be seen that the effect of air flow annealing in the transition chamber on the performance of organic solar cells. Compared with the unannealed device, the performance of the device after the excessive chamber air flow annealing treatment is significantly improved, and the device performance reaches PCE3.69...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com