Device and method for removing nitrogen oxides from hexanedioic acid tail gas

A nitrogen oxide, adipic acid technology, applied in adipic acid production, chemical instruments and methods, nitrous oxide capture, etc., can solve problems such as atmospheric environment damage, and achieve the effect of avoiding overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

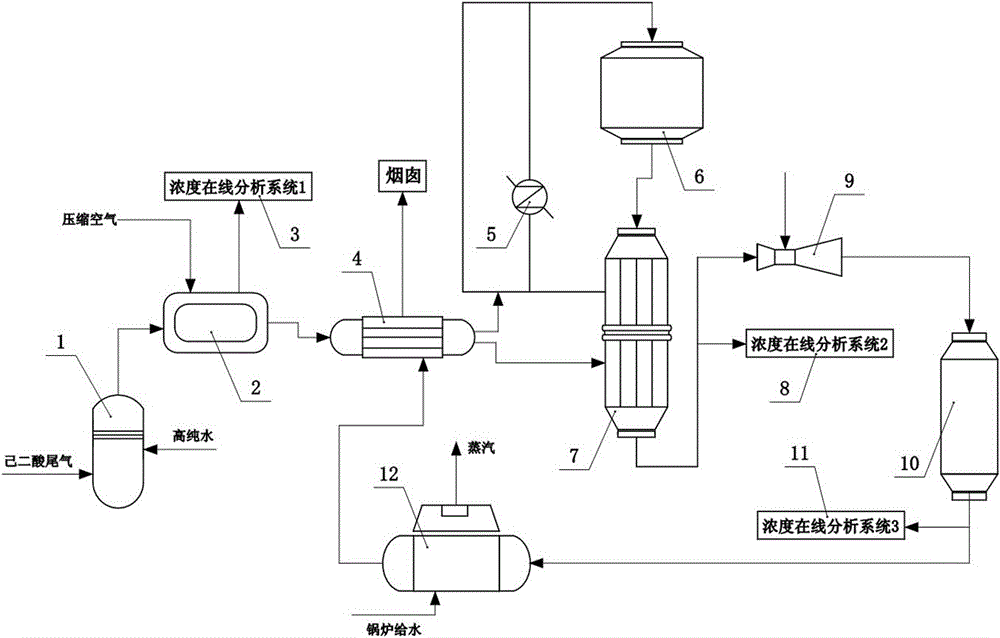

[0027] see figure 1 , a device for removing nitrogen oxides in adipic acid tail gas, comprising a dilution unit, a first reaction unit, and a second reaction unit connected in sequence through pipelines, the dilution unit includes a gas-liquid separation unit connected in sequence through pipelines device 1, compressed air dilution container 2 and the first concentration online analyzer 3; the first reaction unit includes a feed preheater 4, a heating device 5, a first reaction device 6 and a gas / gas exchange unit connected in sequence through pipelines Heater 7 ; the second reaction unit includes a second concentration on-line analyzer 8 , a mixing system 9 , a second reaction device 10 , a third concentration on-line analyzer 11 and a heat recovery device 12 connected in sequence through pipelines.

[0028] A plurality of plug-in thermometers (not shown in the figure) are arranged on the top of the first reaction device 6 and the second reaction device 10, and each thermomet...

Embodiment 2

[0030] see figure 1 , a method for removing nitrogen oxides by utilizing the removal device of nitrogen oxides in the adipic acid tail gas described in embodiment 1, its concrete steps are as follows:

[0031] ①Dilution process: send the adipic acid tail gas to the gas-liquid separator 1, after removing moisture, the tail gas enters the compressed air dilution container 2 and mixes with the compressed air; in the diluted mixed gas, a The volume concentration of nitrous oxide is detected by the first concentration online analyzer 3 to keep the volume concentration of nitrous oxide at 8-15%;

[0032] ②The first reaction process: the diluted mixed gas passes through the feed preheater 4 for feed preheating and countercurrent heat exchange, so that the temperature is raised to 130 ° C ~ 170 ° C, and then the mixed gas is introduced into the heating In the device 5, the temperature of the mixed gas is raised to 380-550°C, and after the temperature is constant, the mixed gas is sen...

Embodiment 3

[0036] Taking an adipic acid plant with an annual output of 140,000 tons as an example, the temperature of the adipic acid tail gas is 32°C, the pressure is 1.9MPa, and the flow rate is 11t / h. The nitrous oxide in the tail gas is 50wt%, and the nitrous oxide and Nitrogen dioxide 0.1wt%, nitrogen 42.2wt%, nitrogen dioxide, nitric oxide and water 7.7wt%.

[0037]First, through the dilution process: send the tail gas of adipic acid to the gas-liquid separator 1, remove the moisture and mix it with compressed air. Depending on the concentration, the volume concentration of nitrous oxide is controlled at 8-15% by the first concentration online analyzer 3 to enter the first reaction process. The flow ratio of compressed air / adipic acid tail gas is set by the DCS system, and can also be adjusted according to the feedback from the first concentration online analyzer 3 or the outlet temperature of the catalyst bed of the nitrous oxide reactor in the first reaction device.

[0038] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com