A kind of polymer adsorbent/cellulose acetate composite membrane material and its preparation method and application

A technology of cellulose acetate and cellulose acetate, which is applied in the field of polymer adsorbent/cellulose acetate composite membrane material and its preparation, can solve the problems of high production cost and long equilibrium period, and achieve lower detection limit and high adsorption effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

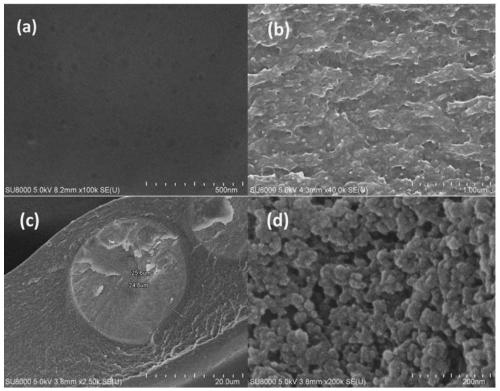

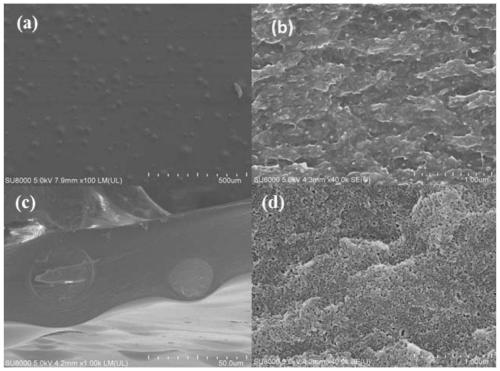

[0036] Embodiment 1, preparation HLB (polystyrene-N-pyrrolidone copolymer)-cellulose acetate composite film

[0037] In terms of mass percentage: 95.9% of cellulose acetate, 4.1% of HLB adsorbent (Oasis HLB, 30 μm in the United States) (that is, the mass ratio of cellulose acetate to HLB adsorbent is 95.9:4.1), including the following steps:

[0038] (1) The formula of the membrane used in the experiment is as follows: 18 g of cellulose acetate; 10 g of dioxane; 70 g of acetone; 2 g of magnesium perchlorate; 0.86 g of HLB adsorbent; Mix in the bottle to configure the casting solution;

[0039] (2) Homogenize the casting solution: place the Triangle brand filled with the above-prepared casting solution in a constant temperature shaking box, keep the temperature at 25°C, and oscillate until the film solution is completely mixed evenly, then HLB-acetic acid can be prepared Casting solution of cellulose composite membrane;

[0040] (3) Membrane production by conventional L-S pha...

Embodiment 2

[0046] Embodiment 2: prepare PS-DVB (polystyrene-divinylbenzene)-cellulose acetate composite film

[0047] In terms of mass percentage, 95.9% of cellulose acetate and 4.1% of PS-DVB adsorbent (Macherey nagel, Germany, 46 μm) (that is, the mass ratio of cellulose acetate to PS-DVB adsorbent is 95.9:4.1), including the following step:

[0048] (1) The formula of the membrane used in the experiment is as follows: cellulose acetate 18g; Dioxane 10g; Acetone 70g; Magnesium perchlorate 2g; PS-DVB adsorbent 0.86g; Mix in the Erlenmeyer flask, configure casting solution;

[0049] (2) Homogenize the casting solution: put the Triangle brand filled with the above-prepared casting solution in a constant temperature shaking box, keep the temperature at 25°C, oscillate until the film solution is completely mixed evenly, and then PS-DVB can be prepared -casting solution of cellulose acetate composite membrane;

[0050] (3) Membrane production by conventional L-S phase inversion method: in...

Embodiment 3

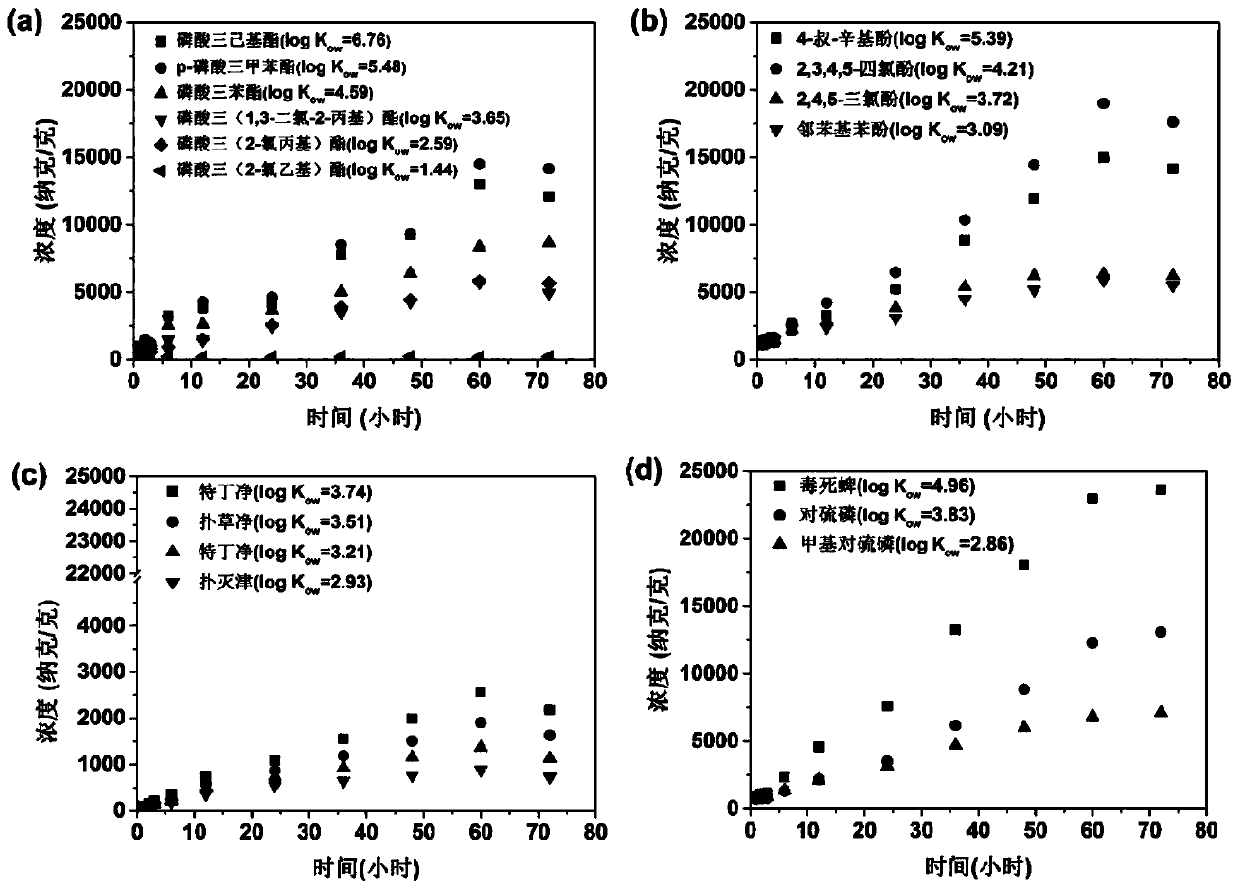

[0056] The enrichment experiment of the HLB-cellulose acetate composite membrane material prepared in embodiment 3 and embodiment 1

[0057] Utilize the HLB-cellulose acetate composite membrane material prepared in Example 1 to enrich 37 kinds of organic compounds (1.49ow ow is the octanol-water partition coefficient).

[0058] Put the composite membrane material prepared in Example 1 with an area of 2×3cm (mass about 0.0326g) into a 1L brown reagent bottle with a 0.8L aqueous solution. In the aqueous solution, 13 kinds of organic phosphorus flame retardants, 8 The concentrations of phenols and 2 estrogens were all 400ng / L, and the concentrations of 6 organophosphorus pesticides and 8 triazine pesticides were 200ng / L. Set up multiple groups of the above-mentioned systems and put them on a constant temperature shaker (150r / min) at 28°C for shaking, and the shaking time is 0h, 1h, 2h, 3h, 6h, 12h, 24h, 36h, 48h, 60h and 72h, each group The shaking time was set in three parall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com