Magnetic adsorbent and preparation method and application thereof

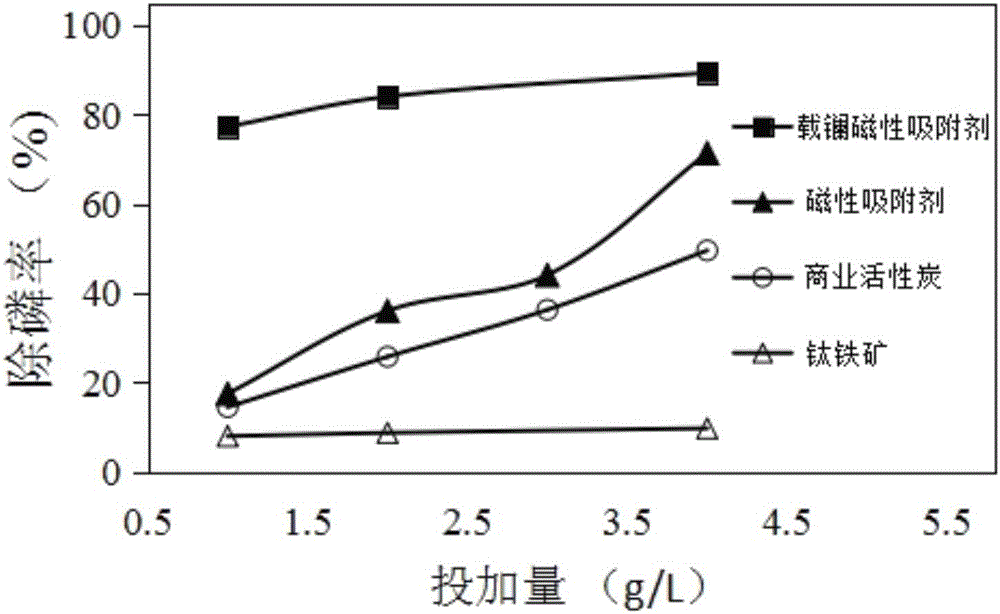

A magnetic adsorbent and reaction product technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, and other chemical processes, can solve problems such as high regeneration costs, environmental pollution, and difficult recycling, and achieve phosphorus removal. Good effect, the effect of promoting adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In this embodiment, the steps of preparing the magnetic adsorbent are as follows:

[0037] (1) Grind the ilmenite and activated carbon separately, pass a 200 mesh sieve to obtain ilmenite powder and activated carbon powder, weigh 12g ilmenite powder and 1.5g activated carbon powder, use a ball mill to mix the ilmenite powder and activated carbon powder evenly Get mixed material;

[0038] (2) Place the mixture material obtained in step (1) in a quartz tube and purge nitrogen to replace the air in the quartz tube, then place it in a microwave oven and react for 10 minutes at a microwave power of 300W, and cool to room temperature. The reaction product is washed with deionized water until the eluate is neutral, and the washed reaction product is dried at 105° C. to remove moisture and naturally cooled to room temperature to obtain a magnetic adsorbent.

Embodiment 2

[0040] In this embodiment, the steps of preparing the magnetic adsorbent are as follows:

[0041] (1) Grind ilmenite and activated carbon separately, pass 200 mesh sieve to obtain ilmenite powder and activated carbon powder, weigh 12g ilmenite powder and 1.5g activated carbon powder, use a high-efficiency multifunctional pulverizer to combine the ilmenite powder with Activated carbon powder is evenly mixed to obtain a mixed material;

[0042] (2) Place the mixture material obtained in step (1) in a quartz tube and purge nitrogen to replace the air in the quartz tube, then place it in a microwave oven and react for 10 minutes at a microwave power of 600W, and cool to room temperature. The reaction product is washed with deionized water until the eluate is neutral, and the washed reaction product is dried at 105° C. to remove moisture and naturally cooled to room temperature to obtain a magnetic adsorbent.

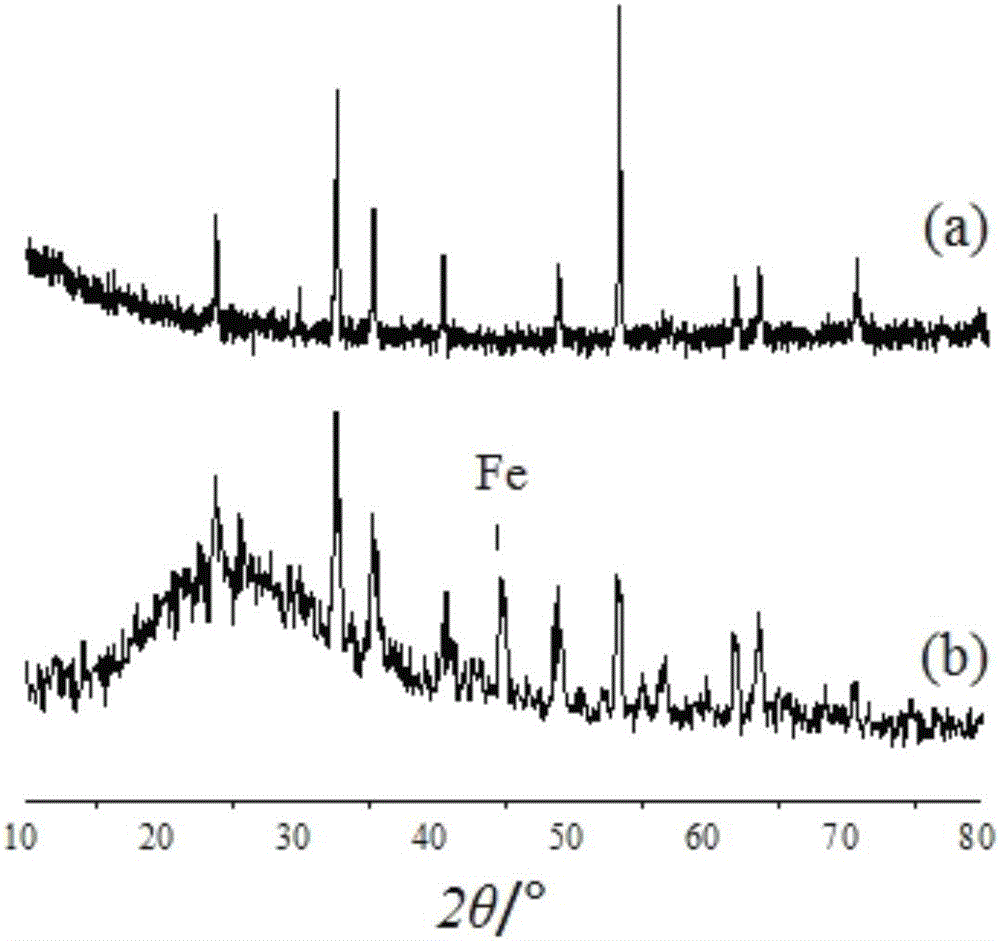

[0043] The XRD patterns of the raw material ilmenite and the magnetic adsorbe...

Embodiment 3

[0045] In this embodiment, the steps of preparing the magnetic adsorbent are as follows:

[0046] (1) Grind ilmenite and activated carbon separately, pass 200 mesh sieve to obtain ilmenite powder and activated carbon powder, weigh 12g ilmenite powder and 3g activated carbon powder, use a high-efficiency multifunctional pulverizer to combine the ilmenite powder and activated carbon Mix the powders uniformly to obtain a mixture;

[0047] (2) Place the mixture material obtained in step (1) in a quartz tube and purge nitrogen to replace the air in the quartz tube, then place it in a microwave oven and react for 10 minutes at a microwave power of 600W, and cool to room temperature. The reaction product is washed with deionized water until the eluate is neutral, and the washed reaction product is dried at 105° C. to remove moisture and naturally cooled to room temperature to obtain a magnetic adsorbent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com