Low Temperature Synthesis of Uranium Nitride Powder

A synthesis method, uranium nitride technology, applied in the direction of nitrogen compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of high impurity content in products, complex process flow, high reaction temperature, etc., to improve sintering activity and shorten the process flow , the effect of low synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

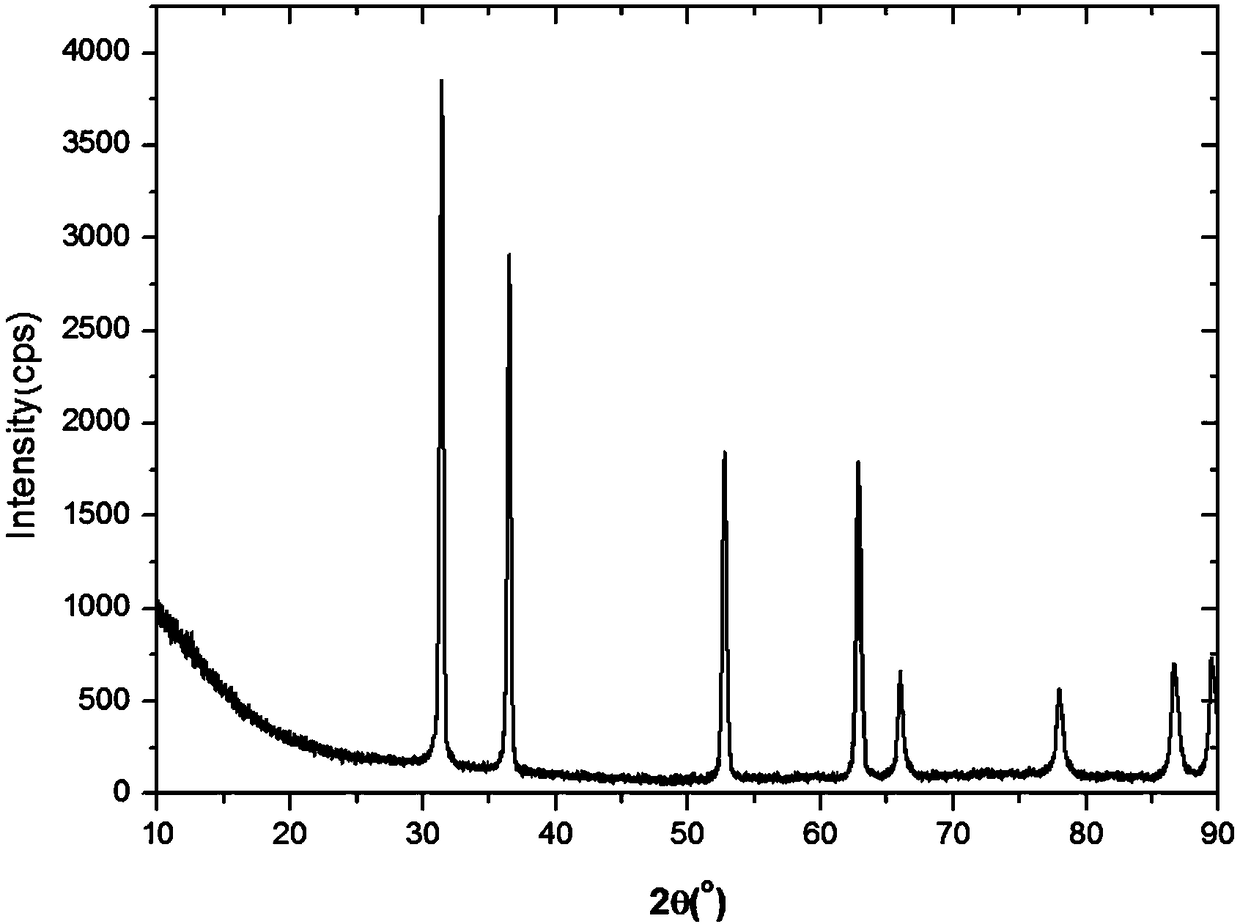

Embodiment 1

[0045] (1) Preparation of metal uranium powder

[0046] Step 1: Introduce hydrogen gas into the reaction furnace with 238g of uranium metal, raise the temperature in the reaction furnace to 225°C, and keep it warm for 16 hours so that the metal uranium and hydrogen fully react to form uranium hydride powder; then increase the temperature in the reaction furnace To 550°C, continue to vacuumize the reaction furnace and keep it warm for 1.5h to dehydrogenate the uranium hydride powder into metal uranium powder, then stop the vacuuming;

[0047] The second step: repeat the operation of the first step twice;

[0048] (2) Quantitative nitriding synthesis of uranium nitride powder

[0049] Raise the temperature in the reaction furnace to 700°C, feed 0.1MPa nitrogen gas through the gas supply device, control the gas flow rate below 1L / min through the mass flow meter on the gas supply device, and rely on the mass flow meter to record the total amount of nitrogen gas introduced, Make ...

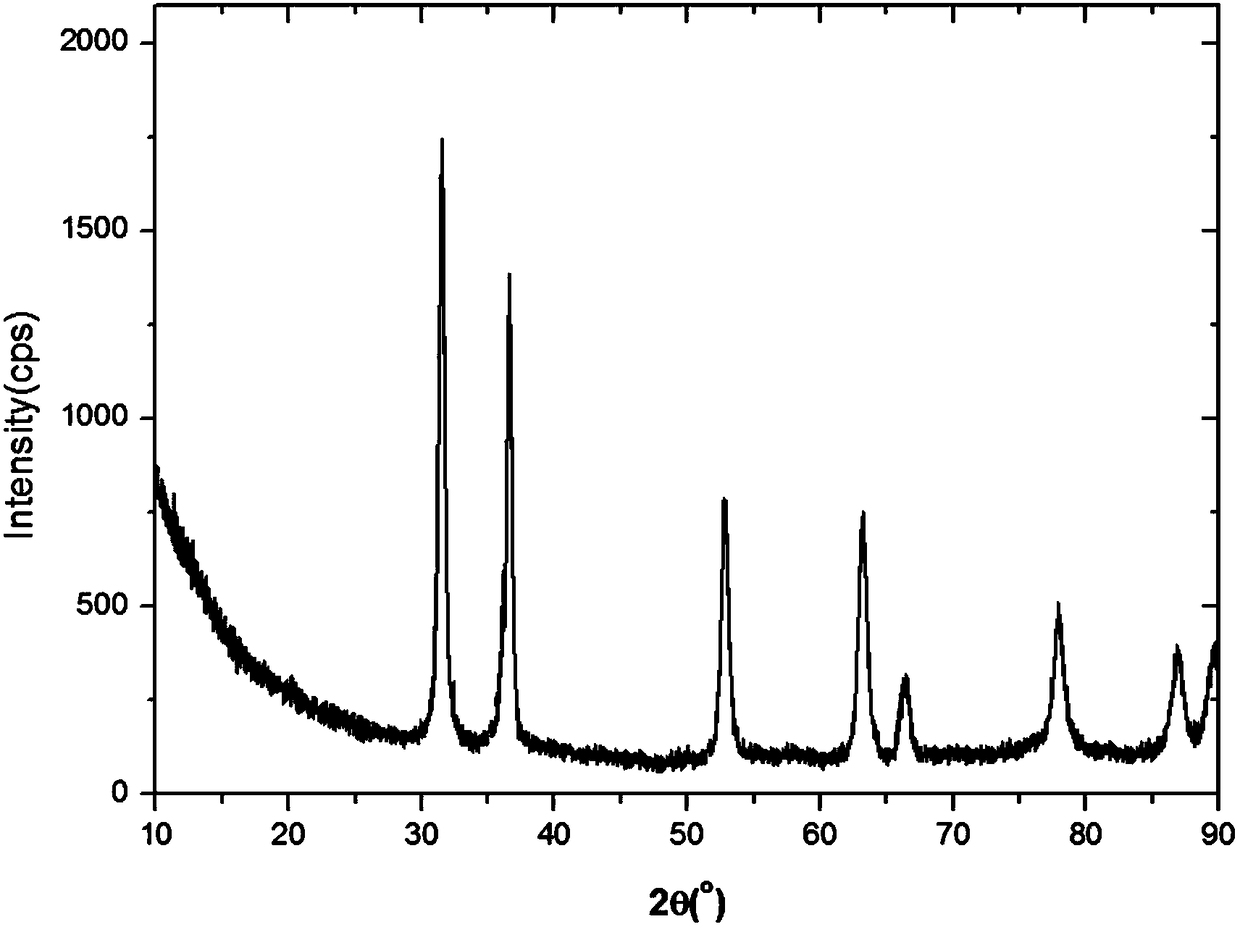

Embodiment 2

[0051] (1) Preparation of metal uranium powder

[0052] Step 1: Introduce hydrogen gas into the reaction furnace with 238g of uranium metal, raise the temperature in the reaction furnace to 255°C, and keep it warm for 8 hours to fully react the metal uranium and hydrogen to form uranium hydride powder; then increase the temperature in the reaction furnace To 650 ℃, continue to vacuumize the reaction furnace, and keep it warm for 1h, so that the uranium hydride powder is dehydrogenated and converted into metal uranium powder, and then stop vacuuming;

[0053] The second step: Repeat the operation of the first step 5 times;

[0054] (2) Quantitative nitriding synthesis of uranium nitride powder

[0055] Raise the temperature in the reaction furnace to 500°C, feed 0.15MPa nitrogen through the gas supply device, control the gas flow rate below 0.2L / min through the mass flow meter on the gas supply device, and rely on the mass flow meter to record the total amount of nitrogen gas ...

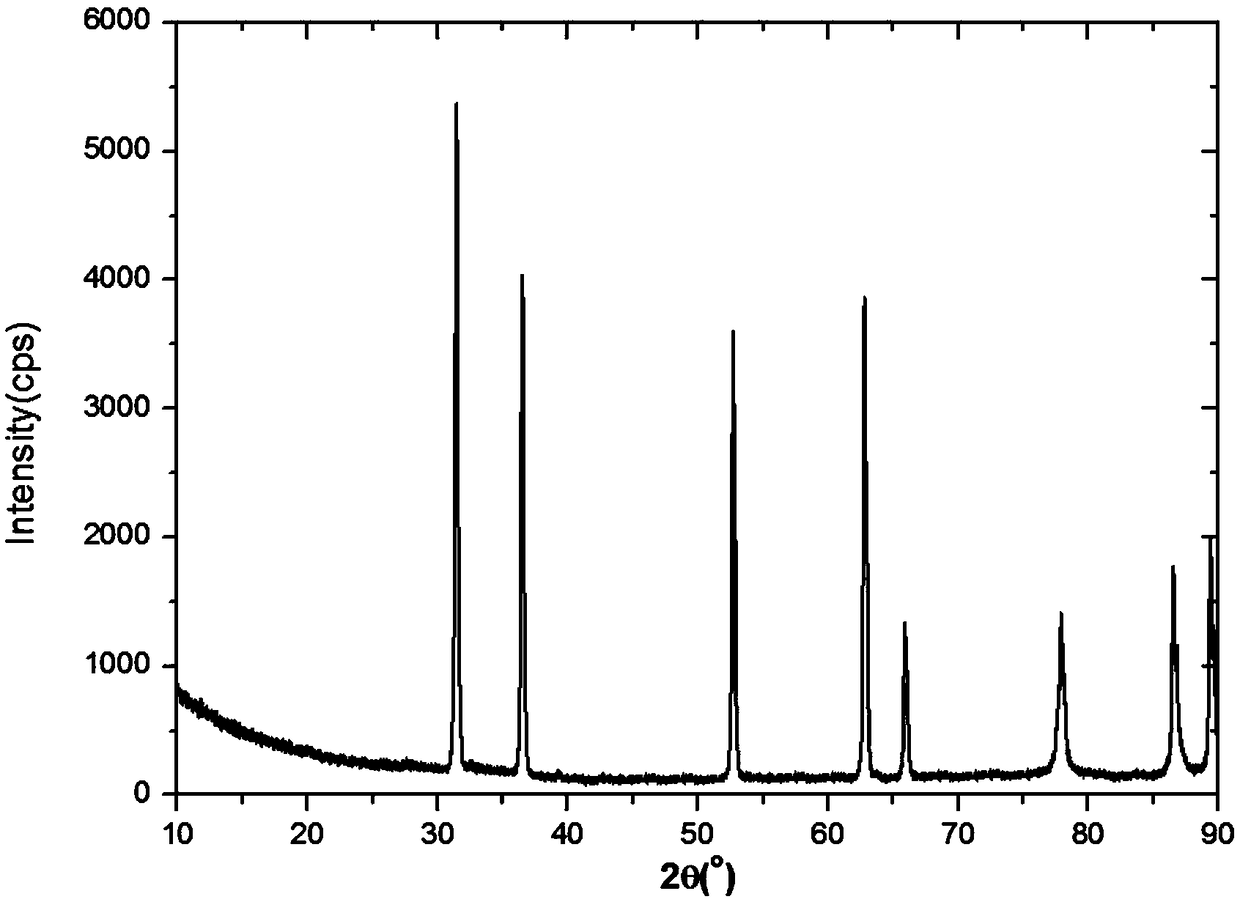

Embodiment 3

[0057] (1) Preparation of metal uranium powder

[0058] Step 1: Introduce hydrogen gas into the reaction furnace with 238g of uranium metal, raise the temperature in the reaction furnace to 275°C, and keep it warm for 24 hours to fully react the metal uranium and hydrogen to form uranium hydride powder; then increase the temperature in the reaction furnace To 750 ℃, continue to vacuumize the reaction furnace, and keep it warm for 2 hours, so that the uranium hydride powder is dehydrogenated and converted into metal uranium powder, and then stop vacuuming;

[0059] The second step: Repeat the operation of the first step 3 times;

[0060] (2) Quantitative nitriding synthesis of uranium nitride powder

[0061] Raise the temperature in the reaction furnace to 800°C, feed 0.2MPa nitrogen through the gas supply device, control the gas flow rate below 2L / min through the mass flow meter on the gas supply device, and rely on the mass flow meter to record the total amount of nitrogen g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com