A hydrothermal-thermal conversion method for preparing active boehmite and alumina porous microspheres from red mud

A technology of porous microspheres and boehmite, which is applied in the fields of alumina/aluminum hydroxide, alumina/hydroxide preparation, chemical instruments and methods, etc., can solve environmental pollution, does not meet the environmental friendly process green, and is cumbersome to handle. and other problems, to achieve the effect of cheap and easy-to-obtain raw materials, uniform appearance and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A hydrothermal-thermal conversion method for preparing active boehmite (AlOOH) porous microspheres using red mud as a raw material, the steps are:

[0034] (1) Mix red mud with 3 mol / L dilute hydrochloric acid at a solid-to-liquid ratio of 1:10g / mL, heat to 100°C and keep it for 2.0h to obtain a slurry, and cool to room temperature;

[0035] (2) Centrifuge the slurry at a speed of 8000 rpm and a centrifugal time of 10 min to obtain supernatant A;

[0036] (3) Add dropwise 2 mol / L NaOH aqueous solution to the supernatant A to adjust the pH to 13.0 to obtain a mixed material liquid;

[0037] (4) Centrifugal separation of the mixed material and liquid at a speed of 8000 rpm and a centrifugal time of 10 min to obtain supernatant B;

[0038] (5) Add urea to the supernatant B to make the urea concentration in the system 0.71 mol / L, mix well, stir at 300 rpm for 20 minutes to obtain a clear reaction solution;

[0039] (6) Place the reaction solution in a hydrothermal reaction kettle, hea...

Embodiment 2

[0044] A method of preparing alumina (Al 2 O 3 ) Hydrothermal-thermal conversion method of porous microspheres:

[0045] (1)~(6) Same as Example 1;

[0046] (7) The AlOOH porous microspheres prepared by the method of Example 1 were placed in a tube furnace, heated to 650°C at a heating rate of 5°C / min, and kept for 2.0 h, and then naturally cooled to room temperature to obtain multi-stage porous Al 2 O 3 Porous microspheres.

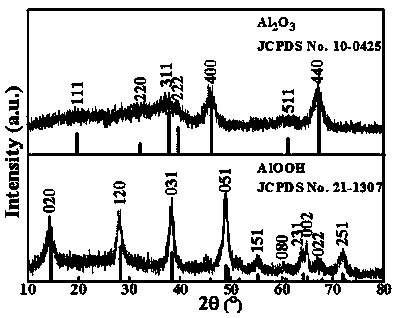

[0047] Al prepared in this example 2 O 3 The XRD pattern of porous microspheres is as follows figure 1 Shown. From figure 1 It can be seen that Al 2 O 3 The XRD pattern of the porous microsphere matches well with the XRD standard card number JCPDS No. 10-0425, indicating that the product composition is relatively pure.

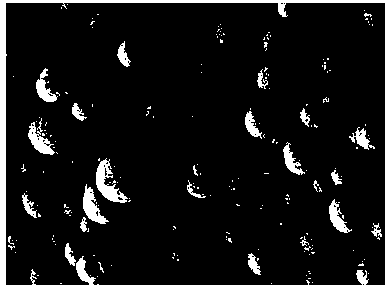

[0048] Al prepared in this example 2 O 3 SEM of porous microspheres such as image 3 Shown. From image 3 It can be seen that Al 2 O 3 The surface of the porous microspheres is assembled from nanosheets and has a porous structure with a pore...

Embodiment 3

[0050] A hydrothermal-thermal conversion method for preparing active boehmite (AlOOH) porous microspheres using red mud as a raw material, the steps are:

[0051] (1) Mix the red mud with 4mol / L dilute nitric acid at a solid-to-liquid ratio of 1:20g / mL, heat to 90°C and keep it for 2.0 h to obtain a slurry, and cool to room temperature;

[0052] (2) Centrifuge the slurry with a rotation speed of 6000 rpm and a centrifugal time of 15 min to obtain supernatant A;

[0053] (3) Add 3 mol / L NaOH aqueous solution dropwise to supernatant A to adjust the pH to 12.9 to obtain a mixed material liquid;

[0054] (4) Centrifugal separation of the mixed material and liquid at a speed of 6000 rpm and a centrifugal time of 15 min to obtain supernatant B;

[0055] (5) Add urea to the supernatant solution B to make the urea concentration in the system 1.67mol / L, mix well, and stir at 400rpm for 30 minutes to obtain a clear reaction solution;

[0056] (6) Put the reaction solution in a hydrothermal reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com