Processing device for deep nitrogen and carbon removal of waste water and technology thereof

A deep denitrification and wastewater treatment technology, applied in the field of water treatment, can solve the problems of insufficient degradation, high dissolved oxygen, and reduced dissolution of denitrification filter, so as to improve ozone removal efficiency, strong load impact resistance, and economical The effect of sexual stability reaching the standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

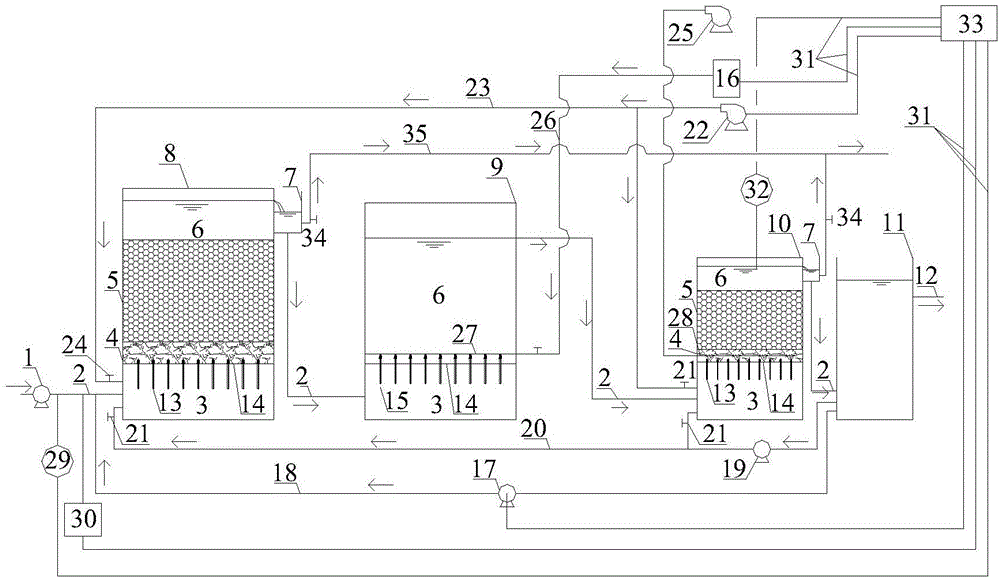

[0034] Example 1: A chemical wastewater treatment flow rate is 60000m 3 / d, the pollutant index before entering this process device is: COD=80mg / L, BOD 5 =10mg / L, TN=35mg / L, NH 3 -N=15mg / L, SS=60mg / L; after this process, the effluent water quality index is: COD=40mg / L, BOD 5 =5mg / L, NH 3 - N = 1.0 mg / L, SS = 5 mg / L, TN = 8.2 mg / L.

example 2

[0035] Example 2: A certain pharmaceutical wastewater, the treatment flow rate is 8000m 3 / d, the pollutant index before entering this process is: COD=120mg / L, BOD 5 =10mg / L, NH 3 -N=29mg / L, SS=50mg / L, TN=40mg / L; after being treated by this process device, the effluent water quality index is: COD=30mg / L, BOD 5 =7mg / L, NH 3 - N = 2.0 mg / L, SS = 4 mg / L, TN = 9.7 mg / L.

[0036] The invention overcomes the shortcomings of the prior art, fully utilizes the process of denitrification and alkali production, avoids the influence of dissolved oxygen on denitrification and denitrification, fully utilizes the ozone tail gas and dissolved oxygen in ozone effluent, and has obvious advantages in energy saving and consumption reduction. promotion and application value.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com