Cement-based plastic material and preparation method thereof

A technology based on molding and cement, applied in the field of materials, can solve the problems of low construction efficiency, insufficient texture, simple shape, etc., and achieve the effect of convenient construction, strong plasticity, good self-cleaning and purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

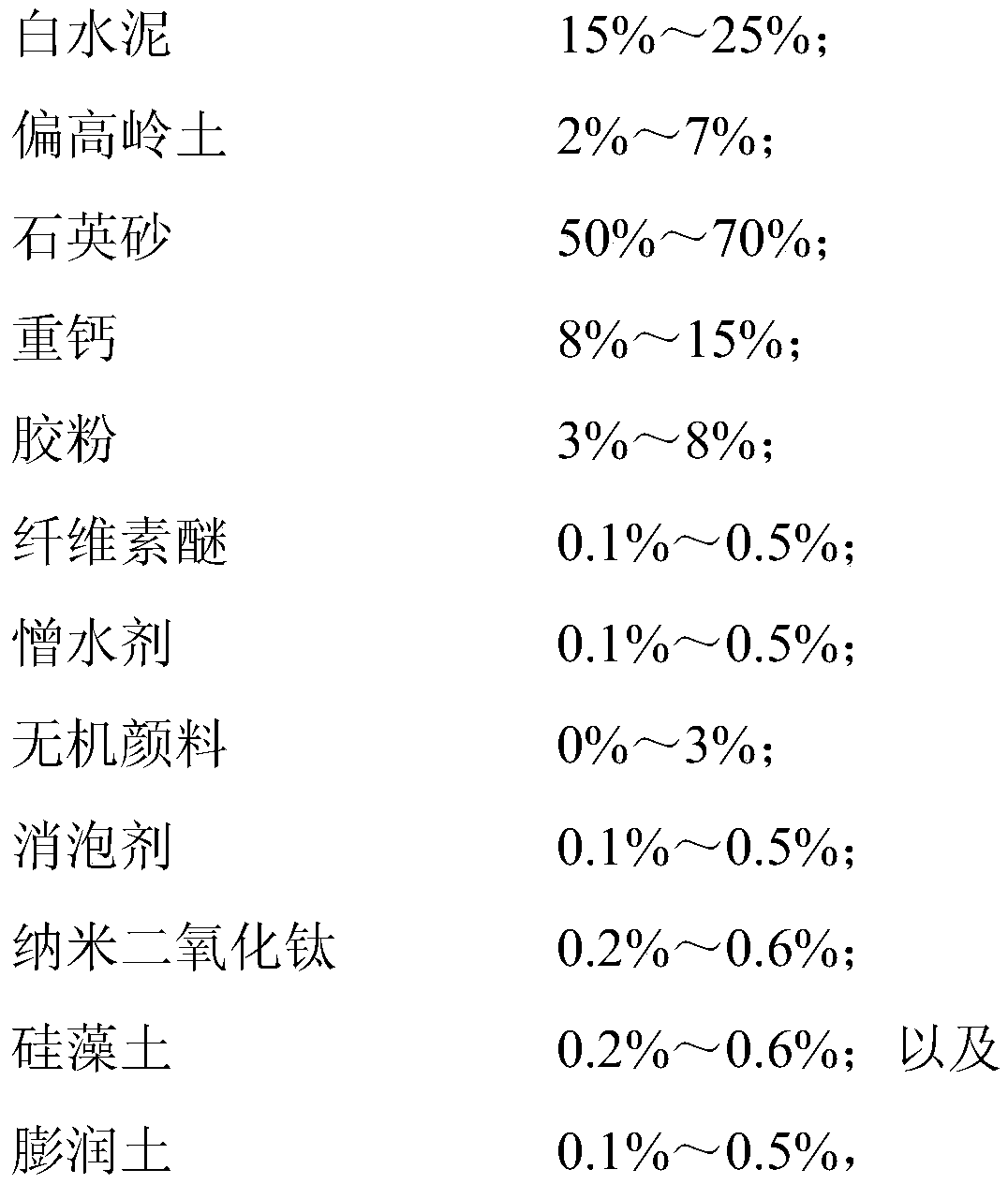

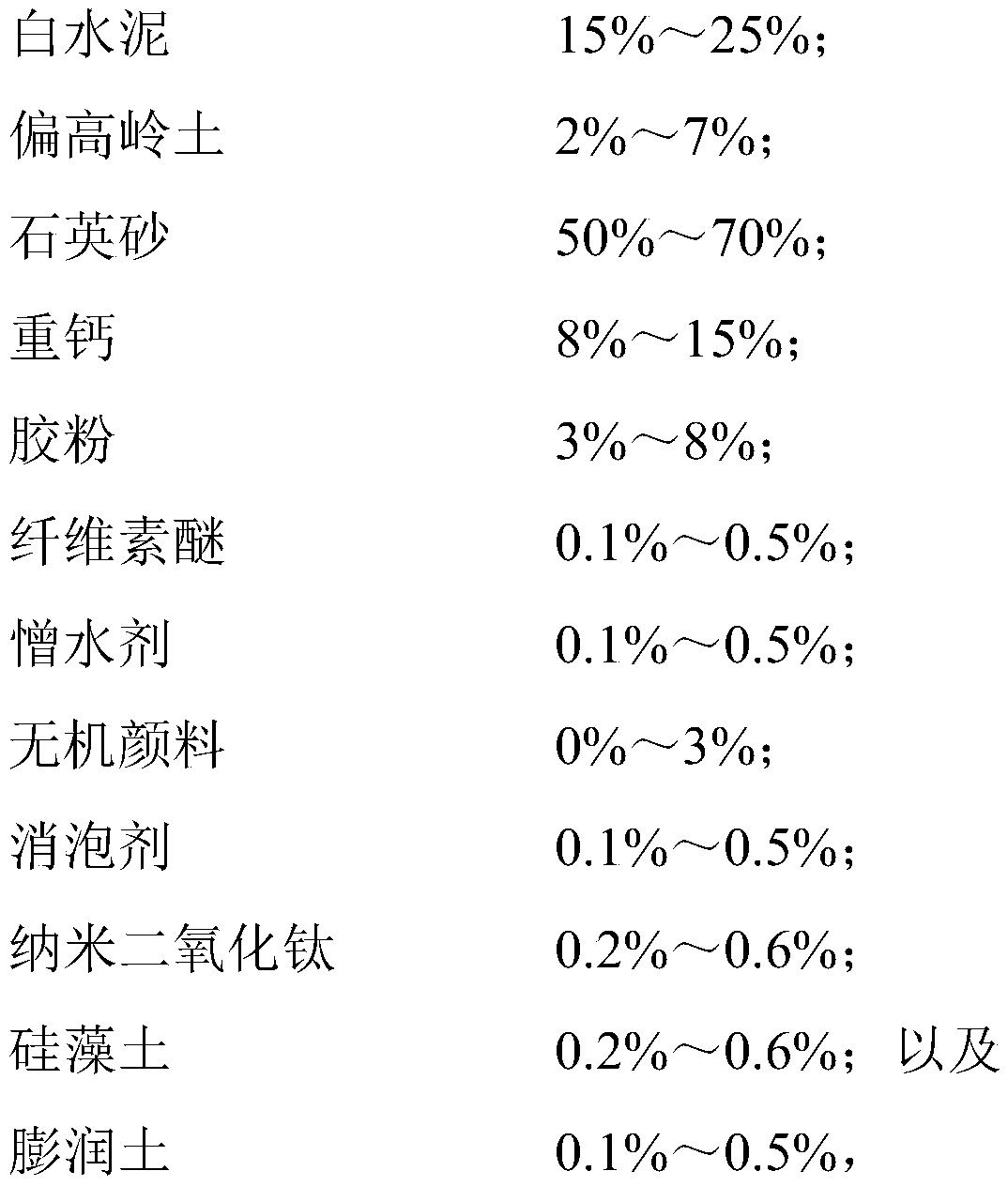

[0031] The specific composition of the cement-based plastic material of the present embodiment is as follows:

[0032] Ingredients weight percentage (%) 52.5 grade white cement 15 Metakaolin 4 Quartz sand 63 Heavy calcium 400 mesh 8 Rubber powder LDM7000P 8 Cellulose ether HPMC30000S 0.2 Hydrophobic agent SILRES Powder D 0.1 Iron Oxide Red 0.7 Defoamer AGITAN P803 0.3 Diatomite-supported porphyrin-modified nano-titanium dioxide 0.4 Sodium bentonite 0.3 total 100

[0033] The preparation steps are as follows:

[0034] Step 1: Diatomaceous earth is dispersed into a thick slurry with deionized water, and then stirred while adding nano-titanium dioxide until uniformly dispersed, wherein the ratio of diatomite to nano-titanium dioxide is 1:1; then the dispersion Dehydrated and dried at 60°C, screened through a 0.1mm square hole sieve to form diatomite-loaded nano-titanium dioxide; impregnated dia...

Embodiment 2

[0037] Prepare the cement-based plastic material of this embodiment according to the same steps as in Example 1, and its specific composition is as follows:

[0038] Ingredients weight percentage (%) 52.5 grade white cement 20 Metakaolin 5.5 Quartz sand 56 Heavy calcium 200 mesh 10 Rubber powder LDM7000P 5 Cellulose ether HPMC30000S 0.3 Hydrophobic agent SILRES Powder D 0.2 Iron oxide yellow 1.5 Defoamer AGITAN P803 0.3 Diatomite-supported Phthalocyanine Modified Nano-TiO2 0.8 Sodium bentonite 0.4 total 100

[0039] Among them, the photosensitizer solution is 5×10 -3 mol / L phthalocyanine aqueous solution, stirred at room temperature for 12h, and other steps were the same as in Example 1.

Embodiment 3

[0041] Prepare the cement-based plastic material of this embodiment according to the same steps as in Example 1, and its specific composition is as follows:

[0042] Ingredients weight percentage (%) 52.5 grade white cement 25 Metakaolin 7 Quartz sand 50 Heavy calcium 200 mesh 10 Rubber powder LDM7000P 3 Cellulose ether HPMC30000S 0.3 Hydrophobic agent SILRES Powder D 0.2 Iron oxide yellow 2.5 Defoamer AGITAN P803 0.3 Diatomite-loaded eosin modified nano-titanium dioxide 1.2 Sodium bentonite 0.5 total 100

[0043] Among them, the photosensitizer solution is 5×10 -4 mol / L eosin aqueous solution, stirred at room temperature for 8h, and other steps were the same as in Example 1.

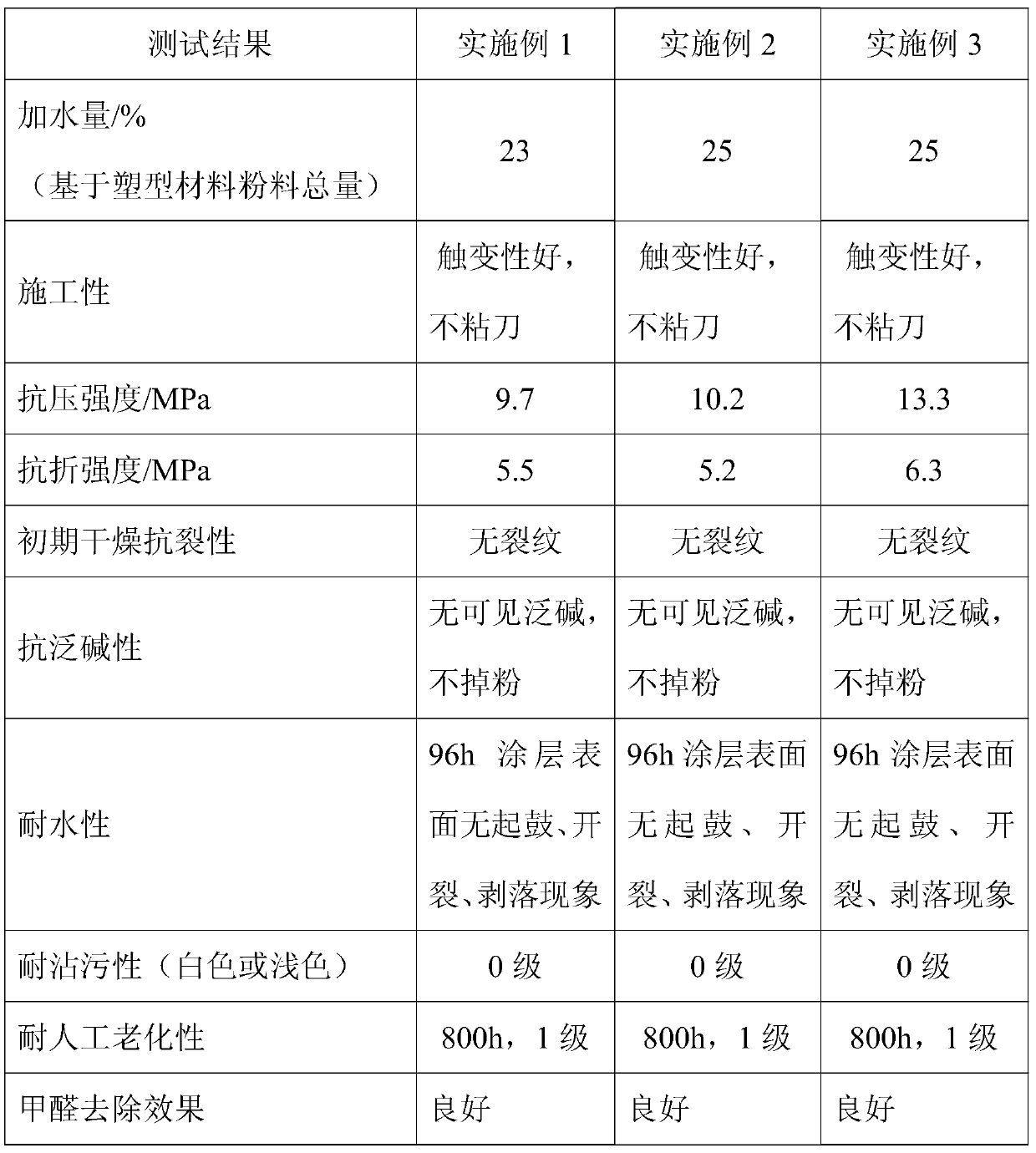

[0044] The cement-based plastic material powder prepared according to the above-mentioned embodiments 1-3 is mixed with water, and its performance characteristic parameters are as follows:

[0045] (The performance t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com