Polypeptide lipidosome capable of transforming shape in lysosome of tumor cell

A plastid, peptide lipid technology, applied in the field of peptide self-assembly nanosystems, can solve problems such as irritation sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Utilize benzoic acid and Fmoc-protected L-amino acids (Fmoc-Lys(Boc)-OH, Fmoc-Asp(tBu)-OH, Fmoc-Gly-OH, Fmoc-Ala-OH, purchased from Jill Biochemical (Shanghai) Co., Ltd. ) as a raw material, on dichlorotrityl chloride resin (purchased from Jill Biochemical (Shanghai) Co., Ltd.), under the conditions of coupling reagents and cleavage reagents commonly used in this field, prepared on the resin by solid phase synthesis Polypeptide (the main body is composed of 6 alanines, the C-terminal of the main body is connected to the tumor cell targeting peptide RGD, and the N-terminal of the main body is modified with a benzene ring). After a simple cleavage reaction, the peptide is separated from the resin, and the pure white peptide powder is obtained after subsequent precipitation, washing, and drying.

[0031] The specific experimental process is as follows:

[0032] First, take 1.01 g of dichlorotrityl chloride resin (purchased from Jill Biochemical (Shanghai) Co., Ltd.) to th...

Embodiment 2

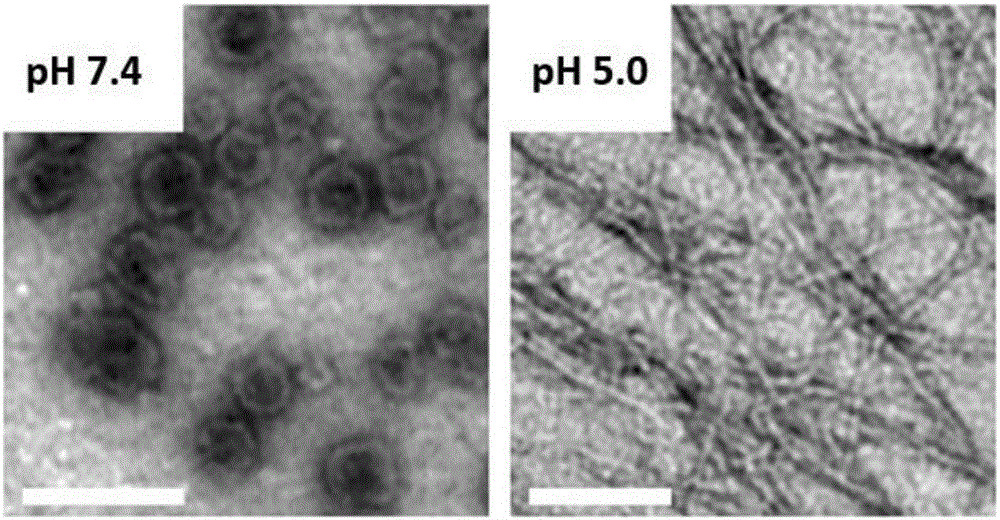

[0041] Dissolve 0.1mg of the polypeptide described in Example 1 in 1mL of ultrapure water, adjust the pH to 7.4 with 0.1M HCl solution and 0.1M NaOH solution, sonicate for 1 minute, and let stand for 30 minutes to prepare an electron microscope sample. Observation of the self-assembled morphology shows a liposome-like structure (see figure 1 ).

[0042] Then the pH of the solution was adjusted to 5.0, and left to stand for 30 minutes to prepare an electron microscope sample, which was observed by a transmission electron microscope, showing a nanofiber morphology (see figure 1 ).

Embodiment 3

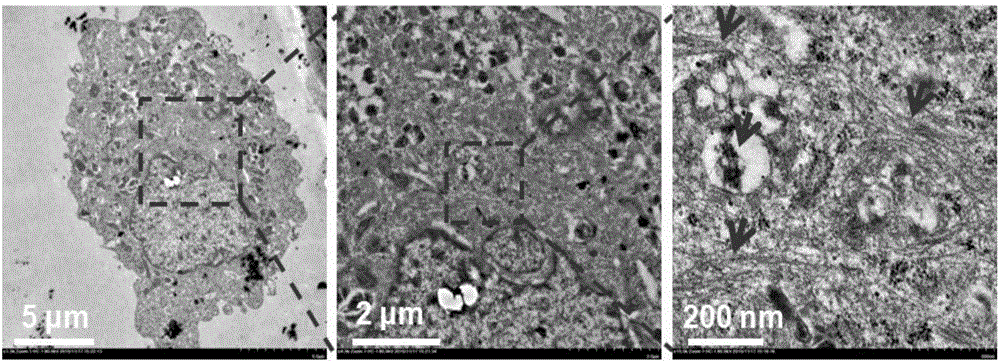

[0044] Observation of self-assembled nanofibers in cells by transmission electron microscope: Incubate the polypeptide with tumor cell MCF-7, collect the cells after 6 hours, centrifuge at 1000r / min at 4°C for 3 minutes, and remove the old medium on the upper layer. Then the cells were fixed with 2.5% glutaraldehyde and 1% osmic acid, dehydrated with different concentrations of ethanol, and embedded with epoxy resin. Then use Diamond Island to cut the cells into ultra-thin sections with a thickness of 60-90nm, place the sections on copper grids, stain with uranyl acetate and lead citrate, and observe the formation of intracellular fibers under a biological transmission electron microscope (HT7700) ( See figure 2 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com