Reversible emulsion for controlling phase transformation through salinity, and preparation method and phase transformation method thereof

An emulsion and phase transformation technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of unstudied emulsion phase reversal process and poor emulsion stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] Embodiment 1, the synthesis of monomer P (St-co-MAn-co-PVBTEAB)

[0093] 1. At room temperature, add 70mmol p-methylstyrene, 60mmol N-bromosuccinimide (NBS), 1mmol lauryl peroxide (LPO) and 100ml carbon tetrachloride ( CCl 4 ), reflux reaction in an oil bath at 60°C for 7h; after the reaction, the succinimide solid was filtered off, and the solvent was spin-dried by a rotary evaporator to obtain p-bromomethylstyrene (PBMS) as a yellow oil.

[0094] At room temperature, add 0.2mol p-bromomethylstyrene (PBMS), 0.2mol triethylamine (TEA) and 100ml tetrahydrofuran (THF) to a 250ml round bottom flask successively, and stir for 20h; after the reaction, filter to obtain a yellow solid product, and washed three times with ether to obtain the salt-sensitive monomer p-vinylbenzyltriethylammonium bromide (PVBTEAB).

[0095] 2. At room temperature, add 30mmol styrene (St), 45mmol maleic anhydride (MA), 5mmol p-vinylbenzyltriethylammonium bromide (PVBTEAB), 1mmol azobisisobutyl N...

Embodiment 2

[0097] Example 2, a reversible emulsion whose salinity can control the phase transition, its preparation and phase transition method

[0098] A reversible emulsion whose phase transition can be controlled by salinity, the composition of the raw materials is as follows:

[0099] Reversible emulsifier 0.18g, Scarland 5# white oil 100mL, deionized water 100mL. Wherein, described reversible emulsifier is formulated by the following components by mass percentage:

[0100] P(St-co-MAn-co-PVBTEAB) 20%,

[0101] Sodium dodecylbenzenesulfonate 30%,

[0102] Sodium Petroleum Sulfonate 32%,

[0103] Potassium salt of perfluoroalkyl ether carboxylate FC-5 18%;

[0104] Preparation method of reversible emulsion:

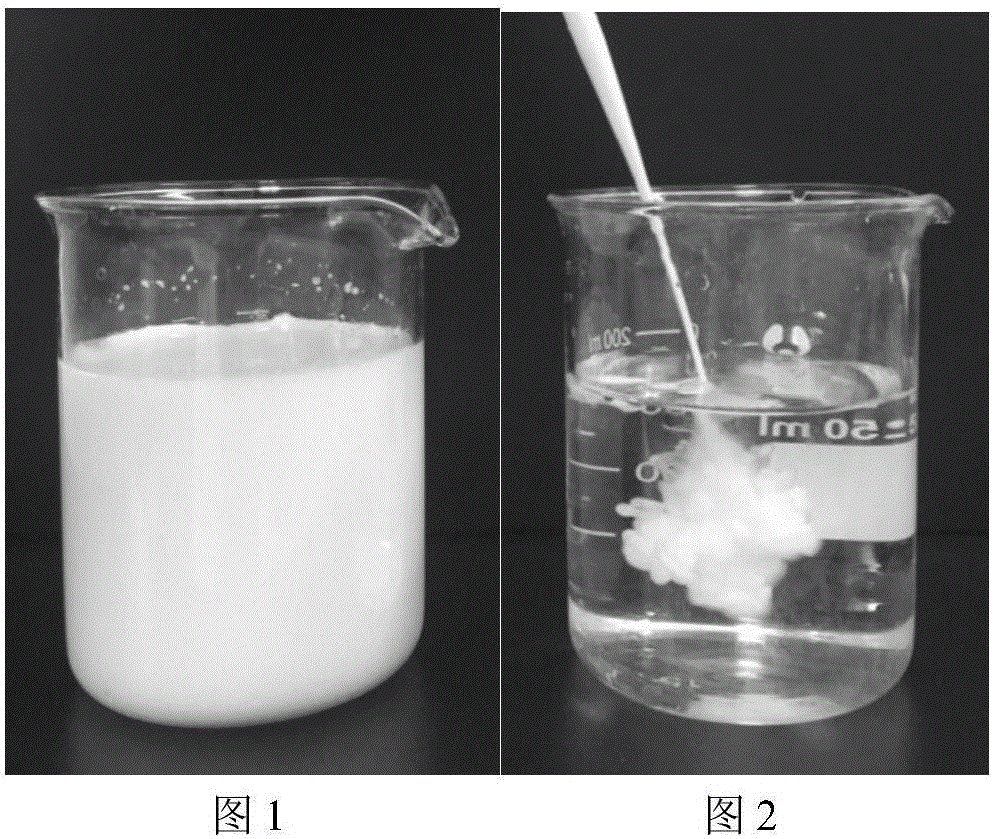

[0105] Mix 0.18g of reversible emulsifier with 100mL of deionized water, stir with a glass rod until completely dissolved; add 100mL of Scarland 5# white oil, and stir at 12000r / min for 10min to form a milky white O / W emulsion (such as figure 1, image 3 ), which is the rev...

Embodiment 3

[0118] A reversible emulsion whose phase transition can be controlled by salinity, the composition of the raw materials is as follows:

[0119] Reversible emulsifier 0.24g, dehydrated crude oil 110mL, deionized water 90mL. Wherein, described reversible emulsifier is formulated by the following components by mass percentage:

[0120]

[0121] Described reversible emulsion preparation method is as follows:

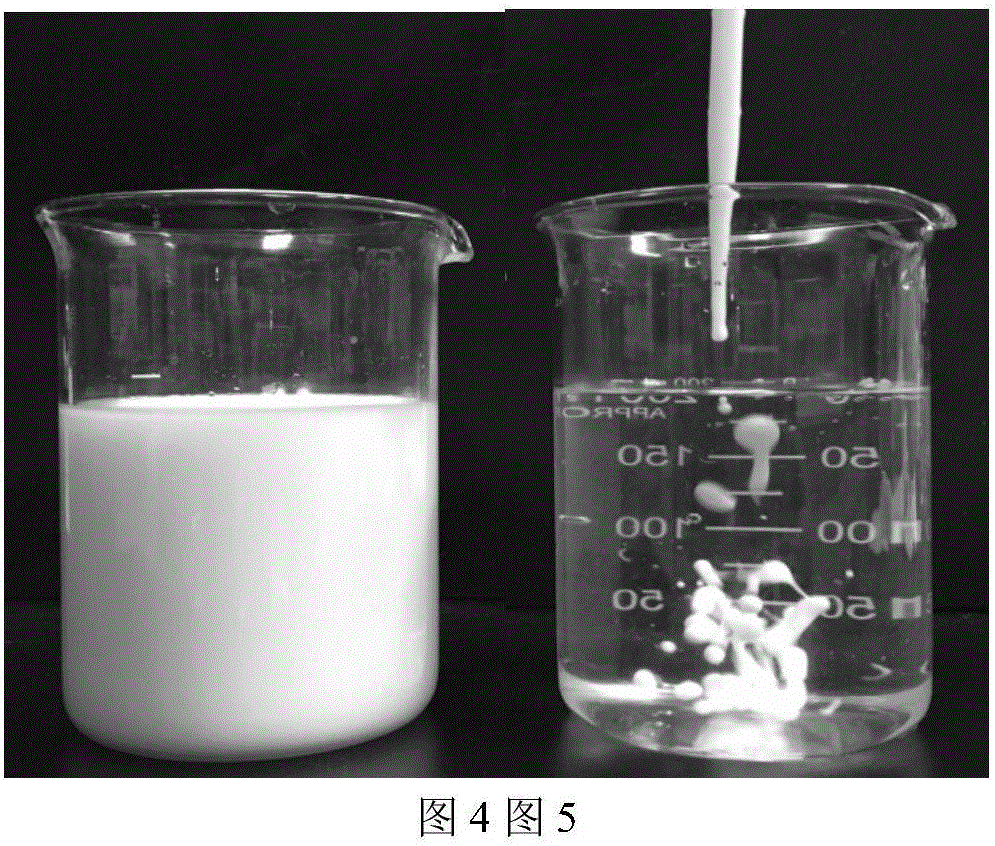

[0122] Mix 0.24g of reversible emulsifier with 90mL of deionized water, stir with a glass rod until completely dissolved; add 110mL of dehydrated crude oil, and stir for 10min at a speed of 12000r / min to form a milky white O / W emulsion, which is the reversible emulsifier of the present invention. Emulsion, denoted as B1 emulsion.

[0123] The stability test shows that the water separation rate of the B1 emulsion after standing for 5 hours is 9%.

[0124] A phase inversion method of a reversible emulsion that can be controlled by salinity for phase inversion, using the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com