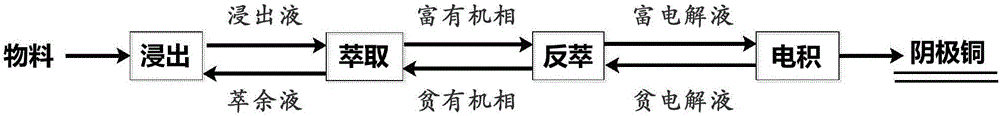

Harmless treatment and high value utilization method for copper-containing sludge

A harmless treatment, copper sludge technology, applied in the direction of process efficiency improvement, photographic technology, instruments, etc., can solve the problems of large environmental pollution, poor washing effect, difficult solid-liquid separation, etc., to reduce complex processes and avoid Colloid formation, good dehydration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

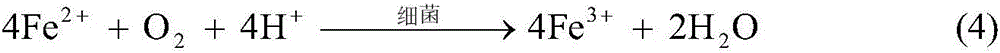

Method used

Image

Examples

Embodiment 1

[0055] The copper-containing sludge produced in the sewage treatment process of a printed circuit board enterprise in Hunan has a water content of 75% after pressure filtration, and its main components include a mixture of copper, iron, calcium hydroxide and sulfate. It contains a small amount of quartz, copper sulfide, and iron sulfide. The main element analysis results of the copper-containing sludge are shown in Table 1-1.

[0056] Table 1-1: Analysis results of main elements of copper-containing sludge on dry basis in Example 1

[0057] element Cu Fe Ca Si Al Ni Zn mn Cr Pb sn content(%) 9.45 25.33 8.42 0.5 0.02 0.003 0.044 0.07 0.015 0.001 0.037

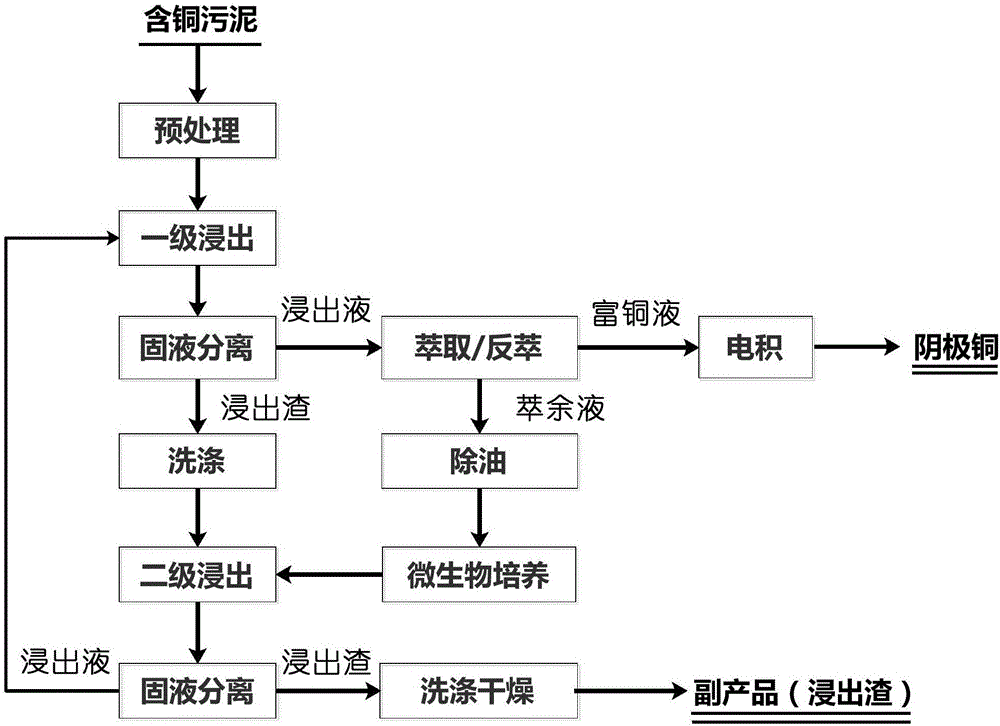

[0058] a kind of like figure 2 The method for harmless treatment and high-value utilization of copper-containing sludge of the present invention includes the following steps:

[0059] (1) Pretreatment of copper-containing sludge: Get 1kg of copper-containing sludge and place i...

Embodiment 2

[0073] The copper-containing sludge produced in the sewage treatment process of a surface treatment company in Jiangsu has a water content of 68% after pressure filtration. The main components are shown in Table 2-1, and the copper phase distribution is shown in Table 2-2.

[0074] Table 2-1: Analysis results of main elements of copper-containing sludge on dry basis in Example 2

[0075] element Cu Fe Ca Si Al Mg mn Na Ni Pb Zn Cr content(%) 14 19.05 12.16 0.026 0.227 1.578 0.21 0.235 0.089 0.002 0.001 0.001

[0076] Table 2-2: Phase distribution of dry base copper in Example 2

[0077] Phase free copper oxide bound copper oxide native copper sulfide secondary copper sulfide total copper content(%) 8.94 5 0.01 0.05 14 Proportion(%) 63.86 35.71 0.07 0.36 100

[0078] a kind of like figure 2 The method for harmless treatment and high-value utilization of copper-containing sludge o...

Embodiment 3

[0093] The copper-containing acidic water of a printed circuit board enterprise in Guangdong precipitated most of the heavy metals by lime precipitation, and the water content of the settled copper-containing sludge was 65% after pressure filtration. The main components are shown in Table 3-1, and the phase distribution of copper As shown in Table 3-2.

[0094] Table 3-1: Analysis results of main elements of copper-containing sludge on dry basis in Example 3

[0095]

[0096] Table 3-2: Phase distribution of dry base copper in Example 3

[0097] Phase free copper oxide bound copper oxide native copper sulfide secondary copper sulfide total copper content(%) 5.14 3.5 0.24 3.77 12.65 Proportion(%) 40.63 27.67 1.90 29.80 100.00

[0098] a kind of like figure 2 The method for harmless treatment and high-value utilization of copper-containing sludge of the present invention includes the following steps:

[0099] (1) Pretreatment of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com