A method for harmless treatment and high-value utilization of copper-containing sludge

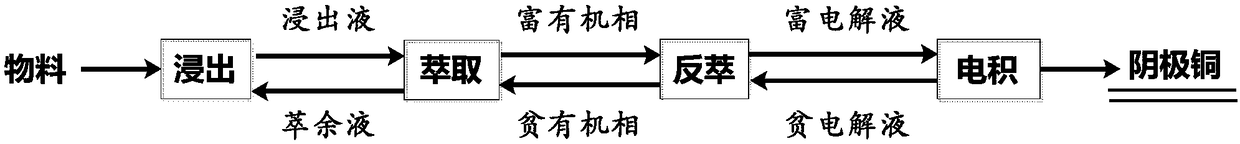

A harmless treatment, copper sludge technology, applied to the improvement of process efficiency, instruments, optics, etc., can solve the problems of poor washing effect, large environmental pollution, difficult solid-liquid separation, etc., to avoid the formation of colloids and reduce complex Good process and dehydration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The copper-containing sludge produced in the sewage treatment process of a printed circuit board enterprise in Hunan has a water content of 75% after pressure filtration, and its main components include a mixture of copper, iron, calcium hydroxide and sulfate. It contains a small amount of quartz, copper sulfide, and iron sulfide. The main element analysis results of the copper-containing sludge are shown in Table 1-1.

[0056] Table 1-1: Analysis results of main elements of copper-containing sludge on dry basis in Example 1

[0057] element

Cu

Fe

Ca

Si

Al

Ni

Zn

mn

Cr

Pb

sn

content(%)

9.45

25.33

8.42

0.5

0.02

0.003

0.044

0.07

0.015

0.001

0.037

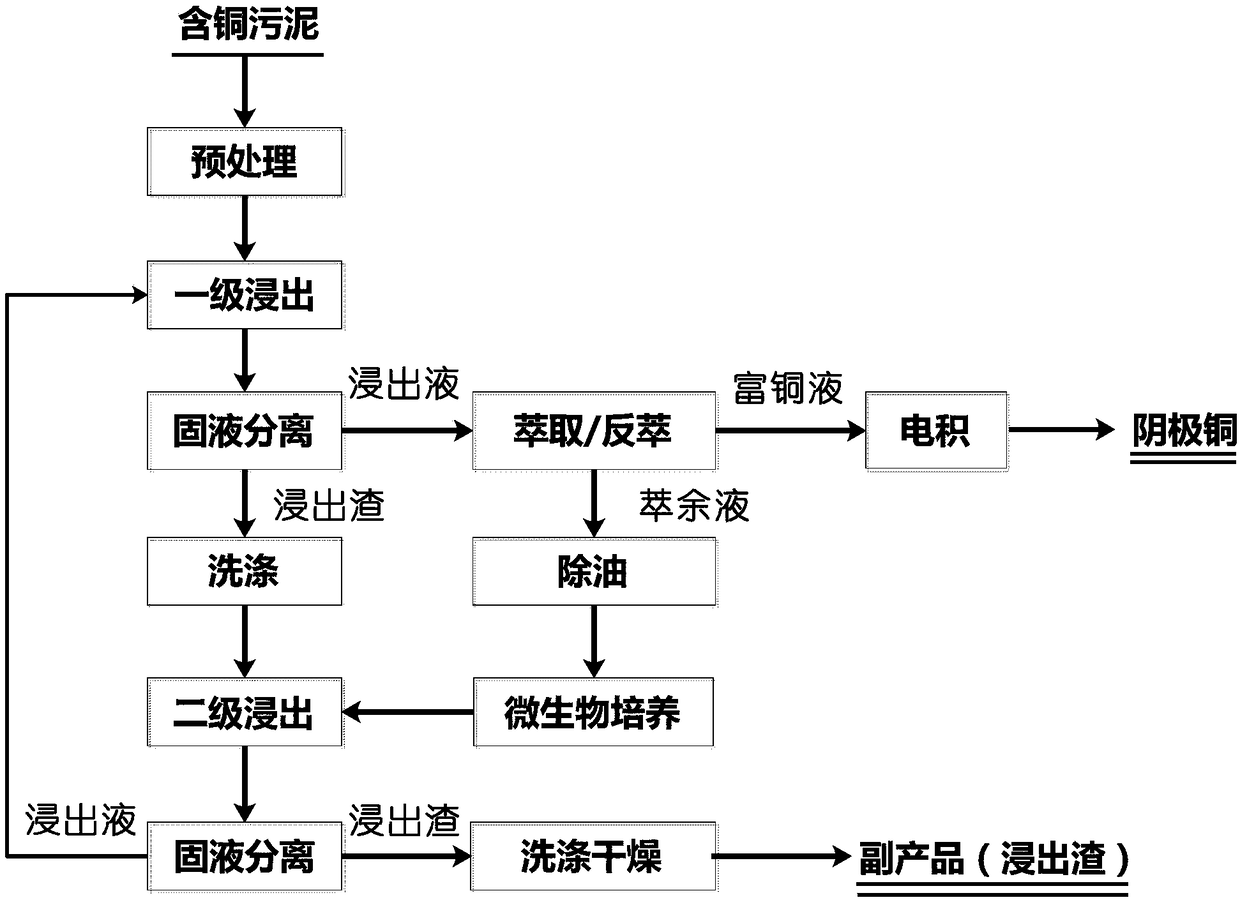

[0058] a kind of like figure 2 The method for harmless treatment and high-value utilization of copper-containing sludge of the present invention includes the following steps:

[0059] (1) Pretreatment of copper-containing sludge: G...

Embodiment 2

[0073] The copper-containing sludge produced in the sewage treatment process of a surface treatment company in Jiangsu has a water content of 68% after pressure filtration. The main components are shown in Table 2-1, and the copper phase distribution is shown in Table 2-2.

[0074] Table 2-1: Analysis results of main elements of copper-containing sludge on dry basis in Example 2

[0075] element

Cu

Fe

Ca

Si

Al

Mg

mn

Na

Ni

Pb

Zn

Cr

content(%)

14

19.05

12.16

0.026

0.227

1.578

0.21

0.235

0.089

0.002

0.001

0.001

[0076] Table 2-2: Phase distribution of dry base copper in Example 2

[0077] Phase

free copper oxide

secondary copper sulfide

total copper

content(%)

8.94

5

0.01

0.05

14

Proportion(%)

63.86

35.71

0.07

0.36

100

[0078] a kind of like figure 2 The me...

Embodiment 3

[0093] The copper-containing acidic water of a printed circuit board enterprise in Guangdong precipitated most of the heavy metals by lime precipitation, and the water content of the settled copper-containing sludge was 65% after pressure filtration. The main components are shown in Table 3-1, and the phase distribution of copper As shown in Table 3-2.

[0094] Table 3-1: Analysis results of main elements of copper-containing sludge on dry basis in Example 3

[0095]

[0096] Table 3-2: Phase distribution of dry base copper in Example 3

[0097] Phase

free copper oxide

secondary copper sulfide

total copper

content(%)

5.14

3.5

0.24

3.77

12.65

Proportion(%)

40.63

27.67

1.90

29.80

100.00

[0098] a kind of like figure 2 The method for harmless treatment and high-value utilization of copper-containing sludge of the present invention includes the following st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com