Treatment method for stripping ABS (Acrylonitrile Butadiene Styrene) electroplated part

A processing method and technology for electroplating parts, which are applied in the directions of microorganism-based methods, methods of using microorganisms, biochemical equipment and methods, etc., which can solve the problem of low corrosiveness of ABS plastic parts, affecting the quality of plastic parts regeneration, and low metal recovery rate. and other problems, to achieve the effect of low corrosiveness, improved utilization level, and low environmental conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

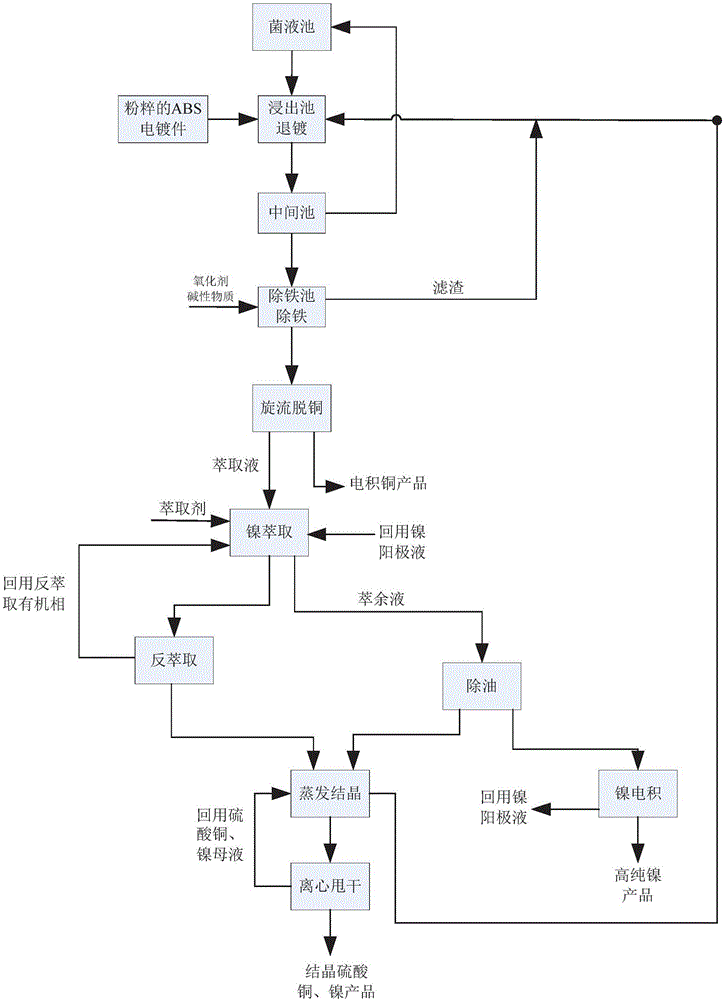

Method used

Image

Examples

Embodiment 1

[0047] A processing method for deplating ABS electroplated parts includes the following steps:

[0048] (1) Preparation of bacteria liquid:

[0049] (11) Purchase purified Thiobacillus ferrooxidans and select liquid medium A: 10 g peptone, 3 g ammonium sulfate, 0.1 g potassium chloride, 0.5 g potassium dihydrogen phosphate, 0.5 g magnesium sulfate, 0.01 g calcium nitrate , And deionized water, the above medium is configured into 700 ml solution, and sterilized for 15 minutes;

[0050] (12) Add 300 ml of 10% ferrous sulfate heptahydrate solution to the above solution, adjust the pH of the solution to 2, and incubate for 10 days, watch the color of the solution change from light green to brownish red, indicating Fe 2+ Slowly become Fe under the action of bacteria 3+ , Measure Fe in solution 3+ Reach 25g / L.

[0051] (13) Use the above-mentioned cultured bacteria liquid as a strain to expand culture, and select liquid medium B: 20 g / L peptone, 5 g / L sodium chloride, 20 g / L urea, 20 g / L ...

Embodiment 2

[0061] A processing method for deplating ABS electroplated parts includes the following steps:

[0062] (1) Preparation of bacteria liquid:

[0063] (11) Purchase purified Thiobacillus ferrooxidans and select liquid medium A: 10 g peptone, 3 g ammonium sulfate, 0.1 g potassium chloride, 0.5 g potassium dihydrogen phosphate, 0.5 g magnesium sulfate, 0.01 g calcium nitrate , And deionized water, the above medium is configured into 700 ml solution, and sterilized for 15 minutes;

[0064] (12) Add 300 ml of 15% ferrous sulfate heptahydrate solution to the above solution, adjust the pH of the solution to 2, and incubate for 15 days, watch the color of the solution change from light green to brownish red, indicating Fe 2+ Slowly become Fe under the action of bacteria 3+ , Measure Fe in solution 3+ Reach 25g / L.

[0065] (13) Use the above-mentioned cultured bacteria liquid as a strain to expand culture, and select liquid medium B: 20 g / L peptone, 5 g / L sodium chloride, 20 g / L urea, 20 g / L ...

Embodiment 3

[0075] A processing method for deplating ABS electroplated parts includes the following steps:

[0076] (1) Preparation of bacteria liquid:

[0077] (11) Purchase purified Thiobacillus ferrooxidans and select liquid medium A: 10 g peptone, 3 g ammonium sulfate, 0.1 g potassium chloride, 0.5 g potassium dihydrogen phosphate, 0.5 g magnesium sulfate, 0.01 g calcium nitrate , And deionized water, the above medium is configured into 700 ml solution, and sterilized for 15 minutes;

[0078] (12) Add 300 ml of 20% ferrous sulfate heptahydrate solution to the above solution, adjust the pH of the solution to 2, and incubate for 10 days, watch the color of the solution change from light green to brown-red, indicating Fe 2+ Slowly become Fe under the action of bacteria 3+ , Measure Fe in solution 3+ Reach 25g / L.

[0079] (13) Use the above-mentioned cultured bacteria liquid as a strain to expand culture, and select liquid medium B: 20 g / L peptone, 5 g / L sodium chloride, 20 g / L urea, 20 g / L amm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com