Lithium ion battery anode material Li2Mn1-xMgxSiO4/C and preparation method thereof

A lithium-ion battery and cathode material technology, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve problems such as poor chemical properties, achieve low synthesis temperature, improve discharge specific capacity, and excellent cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

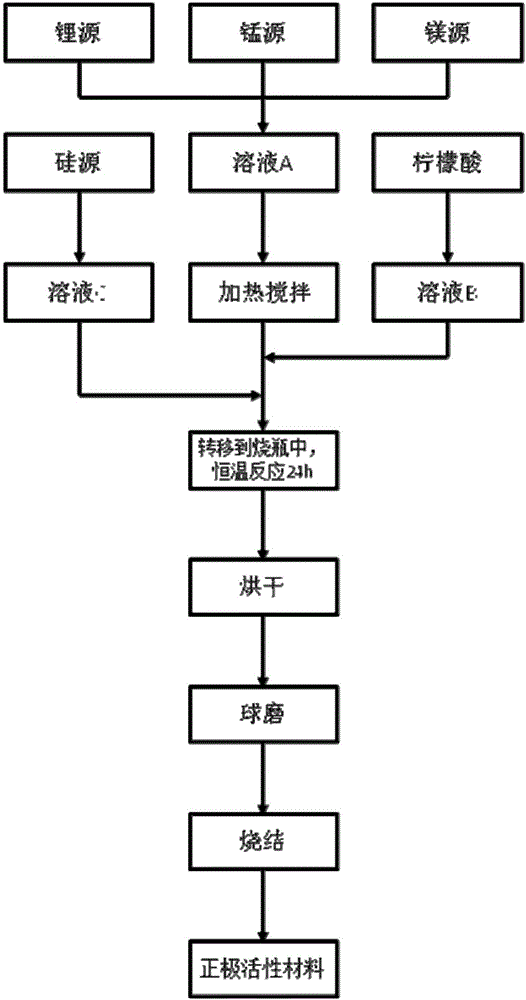

[0033]When the Mg doping amount is 0.05, dissolve 0.02mol (1.3319g) lithium acetate, 0.0095mol (2.3519g) manganese acetate and 0.0005mol (0.0292g) magnesium hydroxide in an appropriate amount of deionized water and record it as solution a; (1.6896g) citric acid was dissolved in an appropriate amount of deionized water, which was recorded as solution b; solution b was slowly added to solution a, and stirred evenly; then 0.01mol (2.083g) orthosilicon Ethyl acetate ethanol solution, stirred for 0.5h; finally the mixed solution was transferred to a single crystal flask with a water bath temperature of 85°C, taken out after 24 hours of reaction, and dried to obtain a xerogel; the xerogel was dispersed in absolute ethanol agent, the rotation speed is 400r / min, the ball-to-material ratio is 8:1, and it is taken out and dried after ball milling for 6 hours; after the mixture is ground evenly, it is sintered at 3°C / min in a tube furnace at 700°C for 10h under an argon atmosphere. After...

Embodiment 2

[0036] When the Mg doping amount is 0.02, dissolve 0.02mol (1.3319g) lithium acetate, 0.0098mol manganese acetate and 0.0002mol magnesium hydroxide in an appropriate amount of deionized water and record it as solution a; dissolve 0.008mol citric acid in an appropriate amount of deionized water , recorded as solution b; slowly add solution b to solution a, and stir evenly; then add 0.01mol ethanol solution of tetraethyl orthosilicate dropwise to the obtained mixed solution, and stir for 0.5h; finally, the mixed solution is transferred to In the single crystal flask, the temperature of the water bath is 85°C, take it out after 24 hours of reaction, and dry to obtain the xerogel; use absolute ethanol as the dispersant, the rotation speed is 400r / min, the ball-to-material ratio is 8:1, After ball milling for 6 hours, take it out and dry it; after the mixture is evenly ground, heat it up to 700°C for 10 hours in a tube furnace under an argon atmosphere at 3°C / min and sinter it for 1...

Embodiment 3

[0039] When the Mg doping amount is 0.02, dissolve 0.02mol (1.3319g) lithium acetate, 0.0098mol manganese acetate and 0.0002mol magnesium hydroxide in an appropriate amount of deionized water and record it as solution a; dissolve 0.024mol citric acid in an appropriate amount of deionized water , recorded as solution b; slowly add solution b to solution a, and stir evenly; then add 0.01mol ethanol solution of tetraethyl orthosilicate dropwise to the obtained mixed solution, and stir for 0.5h; finally, the mixed solution is transferred to In the single crystal flask, the temperature of the water bath is 85°C, take it out after 24 hours of reaction, and dry to obtain the xerogel; use absolute ethanol as the dispersant, the rotation speed is 400r / min, the ball-to-material ratio is 8:1, After ball milling for 6 hours, take it out and dry it; after the mixture is evenly ground, heat it up to 700°C for 10 hours in a tube furnace under an argon atmosphere at 3°C / min and sinter it for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com