Vanadium-manganese-titanium system low-temperature plate catalyst and preparation method thereof

A catalyst, titanium-based technology, applied in the field of vanadium-manganese-titanium low-temperature flat-plate catalyst and its preparation, to achieve huge economic and environmental benefits, high denitrification efficiency, and slow down the deactivation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

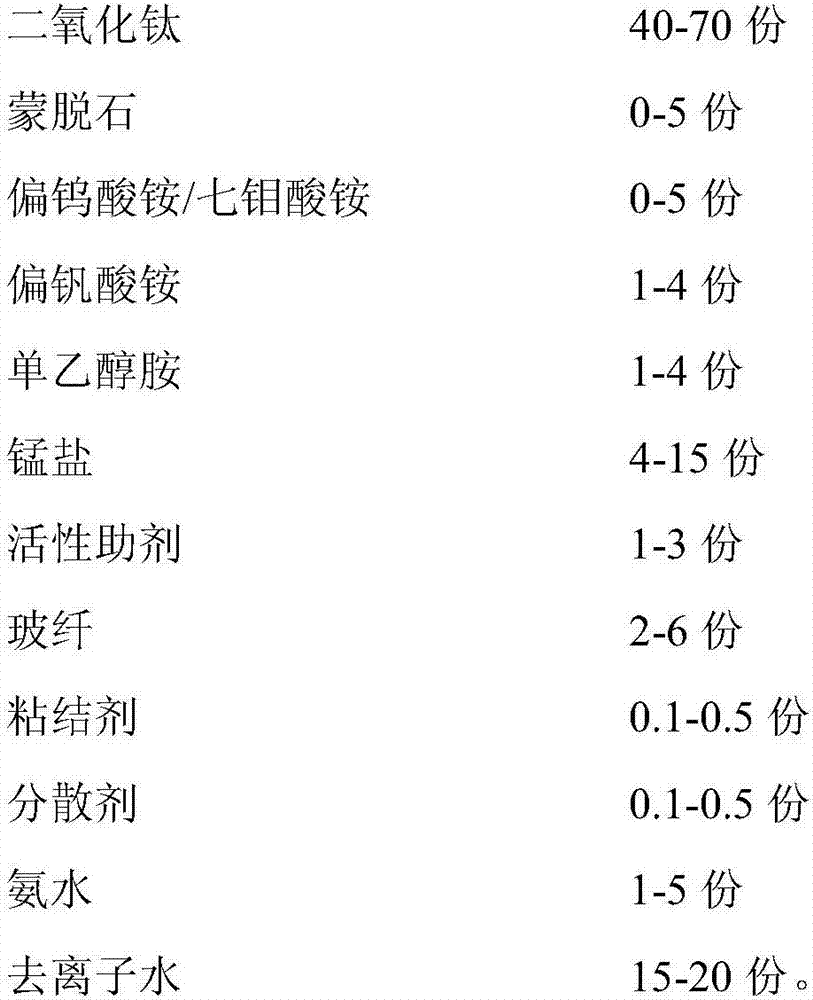

[0043] Various raw materials were weighed according to the weight fraction, a total of 6500g.

[0044]

[0045]Partially deionized water was mixed with 143g of ammonium metavanadate and 156g of monoethanolamine, heated to 70°C with a heating mantle, stirred until completely dissolved, cooled to room temperature for later use, and solution R2 was obtained. Part of deionized water and 455g of manganese nitrate were mixed and stirred for about 10 minutes to obtain solution R3. Part of deionized water and 195g of cerium nitrate were mixed and stirred for about 10min to obtain solution R4. The weighed titanium dioxide powder (average particle size 0.63μm, specific surface area 118m 2 / g) into a small kneader. Pour the weighed montmorillonite powder into a small kneader, close the lid, turn on the stirring function of the kneader, and mix well. Open the upper cover of the kneader, pour the remaining deionized water evenly into the kneader under stirring state, close the cover,...

Embodiment 2

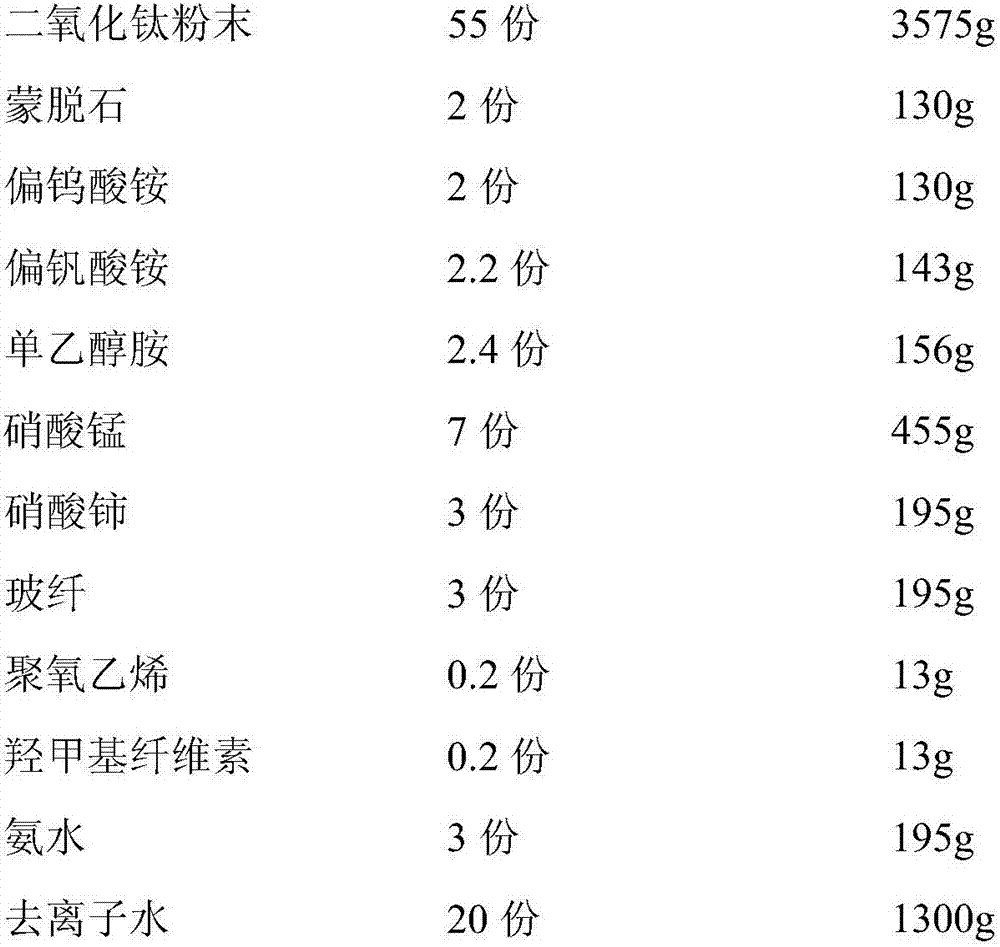

[0047] Various raw materials were weighed according to the weight fraction, a total of 6500g.

[0048]

[0049] Mix part of deionized water, 65g of ammonium metavanadate and 65g of monoethanolamine, heat to 80°C with a heating mantle, stir until completely dissolved, cool to room temperature for later use, and obtain solution R2. Part of the deionized water and 650 g of manganese nitrate were mixed and stirred for about 10 min to obtain solution R3. Part of the deionized water was mixed with 130 g of cerium nitrate and 65 g of copper sulfate, and stirred for about 10 min to obtain solution R4. The weighed titanium dioxide powder (average particle size 0.85μm, specific surface area 112m 2 / g) into a small kneader. Pour the remaining deionized water evenly into the kneader under stirring, cover the lid, and stir for 15 minutes. Open the upper cover of the kneader, slowly and evenly pour the R2 solution into the kneader under stirring, cover the cover, and stir for 15 minut...

Embodiment 3

[0051] Various raw materials were weighed according to the weight fraction, a total of 6500g.

[0052]

[0053] Mix part of deionized water, 260g of ammonium metavanadate and 260g of monoethanolamine, heat to 70°C with a heating mantle, stir until completely dissolved, cool to room temperature for later use, and obtain solution R2. Part of the deionized water and 260 g of manganese acetate were mixed and stirred for about 10 min to obtain solution R3. Part of deionized water and 65g of cobalt nitrate were mixed and stirred for about 10 minutes to obtain solution R4. The weighed titanium dioxide powder (average particle size 0.88μm, specific surface area 108m 2 / g) into a small kneader. Pour the remaining deionized water evenly into the kneader under stirring, cover the lid, and stir for 15 minutes. Open the upper cover of the kneader, slowly and evenly pour the R2 solution into the kneader under stirring, cover the cover, and stir for 15 minutes. Open the upper cover of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com