Preparation method of zinc oxide nanorod/g-C3N4 nanosheet composite photocatalyst material

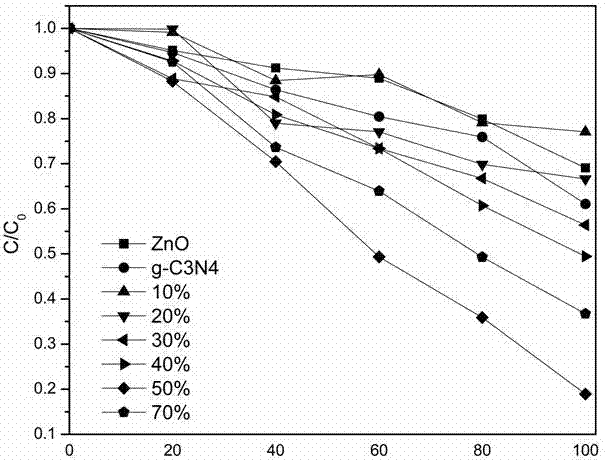

A zinc oxide nanorod, composite photocatalysis technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as the reduction of photocatalytic efficiency, and achieve simple methods, improved degradation efficiency, The effect of increased absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

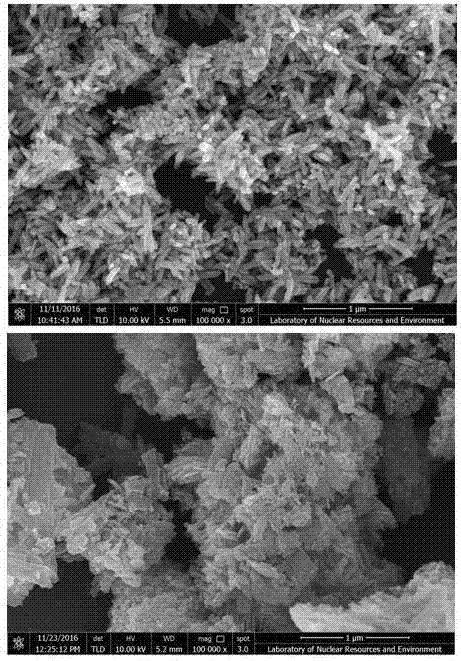

[0023] Step 1: g-C 3 N 4 Preparation of nanosheets.

[0024] (1) Accurately weigh 3g of melamine and put it into a ceramic crucible with a lid, put the lid on and place it in a tube-type heating furnace to raise the temperature to 550°C at a heating rate of 5°C / min, and keep the temperature at 550°C for 4 hours of heat treatment , to obtain g-C in the form of light yellow block 3 N 4 nanomaterials, which are then ground up for later use.

[0025] (2) Accurately weigh 1g block g-C 3 N 4 The nanomaterials were placed in a beaker containing a mixed acid of 20ml of concentrated sulfuric acid and 20ml of concentrated nitric acid, and stirred at room temperature for 4 hours. Then the mixture was diluted with deionized water to obtain a white precipitate. The white precipitate was collected and washed 5 times with deionized water to obtain g-C 3 N 4 Nanosheets.

[0026] Step 2: ZnO nanorods / g-C 3 N 4 Preparation of nanosheet composite photocatalytic materials.

[0027] (...

Embodiment 2

[0031] Step 1: Same as Example 1.

[0032] Step 2: ZnO nanorods / g-C 3 N 4 Preparation of nanosheet composite photocatalytic materials.

[0033] (1) Same as Example 1.

[0034] (2) Accurately weigh 0.25g of cetyltrimethylammonium bromide with an electronic balance, and dissolve it in 30mL of absolute ethanol to form a uniform solution. Then pipette it and slowly drop into 6ml Zn precursor solution, stir for 30min until the solution is uniform and stable. Then add 0.489g g-C 3 N 4 Nanosheets (convert zinc acetate dihydrate to the mass of zinc oxide, making zinc oxide and g-C 3 N 4 The mass ratio of nanosheets is 2:10), stirring for 30 minutes, and ultrasonication for 30 minutes, so that g-C 3 N 4 The nanosheets are uniformly dispersed in the solution.

[0035] (3) Same as Example 1.

Embodiment 3

[0037] Step 1: Same as Example 1.

[0038] Step 2: ZnO nanorods / g-C 3 N 4 Preparation of nanosheet composite photocatalytic materials.

[0039] (1) Same as Example 1.

[0040] (2) Accurately weigh 0.25g of cetyltrimethylammonium bromide with an electronic balance, and dissolve it in 30mL of absolute ethanol to form a uniform solution. Then pipette it and slowly drop into 6ml Zn precursor solution, stir for 30min until the solution is uniform and stable. Then add 0.326g g-C 3 N 4 Nanosheets (convert zinc acetate dihydrate to the mass of zinc oxide, making zinc oxide and g-C 3 N 4 The mass ratio of nanosheets is 3:10), stirring for 30 minutes, and ultrasonication for 30 minutes, so that g-C 3 N 4 The nanosheets are uniformly dispersed in the solution.

[0041] (3) Same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com