Concave surface gold@silver platinum heterogeneous composite nanoparticles having excellent catalytic and absorption properties and preparing method thereof

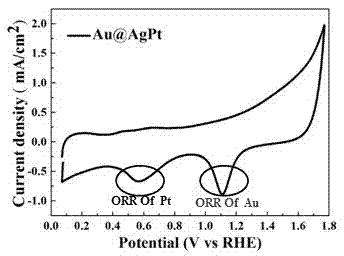

A composite nanoparticle, light absorption technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of not showing good surface plasmon resonance absorption characteristics, difficult to prepare gold-silver-platinum composite nanoparticles with optical characteristics, etc. Good surface plasmon resonance absorption performance, excellent catalytic activity, uniform particle size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

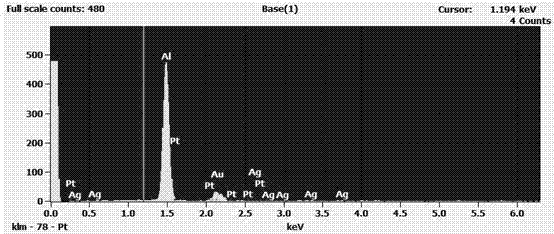

[0033] concave gold @ Preparation of silver-platinum composite nanoparticles

[0034] First, polydiallyldimethylammonium chloride (M w =100000-200000, 20 wt%), chloroauric acid (HAuCl 4 ) aqueous solution, mixed and shaken, moved into 220 degree oil bath and reacted for 3 hours to prepare gold nano-octahedrons with a size of 45 nanometers and obtain gold octahedron seed solution, wherein polydiallyldimethylammonium chloride (M w =100000-200000, 20 wt%), chloroauric acid (HAuCl 4 ) concentration of the aqueous solution is 0.025 mol / L and 0.0005 mol / L respectively. Then take 50 ml gold octahedron seed solution, add silver nitrate (AgNO 3 ), ascorbic acid (AA), potassium tetrachloroplatinate (K 2 PtCl 4 ) aqueous solution to shake well to obtain the reaction precursor solution, in which ascorbic acid (AA), silver nitrate (AgNO 3 ), potassium tetrachloroplatinate (K 2 PtCl 4 ) in the reaction system with final concentrations of 0.0025 mol / L, 0.000015 mol / L, and 0.0000...

Embodiment 2

[0036] gold @ platinum, gold @ Preparation of Silver Core-Shell Composite Nanoparticles

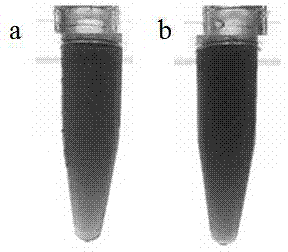

[0037] Take 8 ml gold octahedron seed solution into reaction flasks A and B, then add ascorbic acid (AA), potassium tetrachloroplatinate (K 2 PtCl 4 ), where ascorbic acid (AA), potassium tetrachloroplatinate (K 2 PtCl 4 ) concentrations are 0.0025 mol / L, 0.000015 mol / L, add ascorbic acid (AA), silver nitrate (AgNO 3 ), where ascorbic acid (AA), silver nitrate (AgNO 3 ) final concentrations are 0.0025 mol / L and 0.000015 mol / L, respectively. Finally, reaction bottles A and B were placed in a 220-degree oil bath for 3 hours to obtain a gold@platinum and gold@silver core-shell composite nanoparticle colloidal solution, which was centrifuged at a speed of 8,000 rpm for 20 minutes in a high-speed centrifuge. The colorless solution in the upper layer in the centrifuge tube was removed to obtain a purple and red precipitated product. The precipitated product was ultrasonically clea...

Embodiment 3

[0039] Concave gold composed of different elements @ Preparation of silver-platinum composite nanoparticles

[0040] Take 10 milliliters of colloid 1 solutions and put them into reaction flasks C, D, E, and F respectively, and add 0.0192, 0.0576, 0.096, and 0.1344 milliliters of them at room temperature. 2 PtCl 4 ) aqueous solution, and then reacted in a 220-degree oil bath for 3 hours to obtain a colloidal solution of concave gold@silver-platinum heterogeneous composite nanoparticles with different components. Utilize a high-speed centrifuge to centrifuge at a speed of 10,000 rpm for 30 minutes, remove the colorless solution in the upper layer of the centrifuge tube to obtain a blue precipitate product; use deionized water to ultrasonically clean the precipitate product for 3-5 times to obtain the following: Figure 9 The shown gold-silver-platinum molar ratios are 100:6:3, 100:12:3, 100:18:3, 100:24:3 concave gold@silver-platinum heterogeneous composite nanoparticles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com