Method for recovering high-purity silicon powder from crystal silicon cutting waste material slurry

A technology for cutting waste and high-purity silicon powder, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve problems such as harsh operating environment, increased cost of silicon powder, and difficulty in recycling waste slurry, so as to reduce environmental pollution, Reduced separation time and less contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

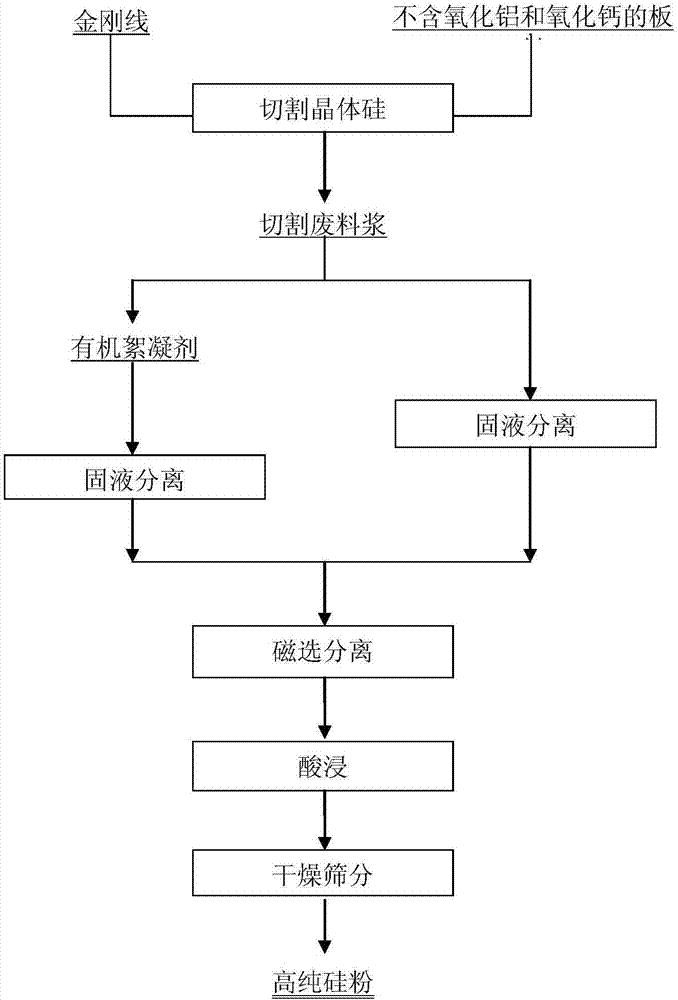

Image

Examples

Embodiment 1

[0053] A method for reclaiming high-purity silicon powder from the cutting waste slurry of crystalline silicon, comprising the following steps:

[0054] Step 1, preparation before cutting

[0055] (1) The cutting wire of the multi-wire cutting machine adopts resin diamond wire;

[0056] (2) The holding material of crystalline silicon adopts epoxy resin board;

[0057] Step 2, waste slurry treatment

[0058] (1) Cut crystalline silicon with a multi-wire cutting machine, collect the cutting waste slurry, the composition and mass percentage of the cutting waste slurry are: 40% water-based cooling liquid, 58% silicon powder, and 1% metal impurities , 1% small diamond particles;

[0059] (2) Add 5kg of starch to the 500kg diamond wire cutting crystalline silicon waste slurry, settling and stratifying, the upper layer is the supernatant, and the lower layer is the sedimentation material, carry out a solid-liquid separation, and the supernatant of the upper layer returns to the cr...

Embodiment 2

[0064] A method for reclaiming high-purity silicon powder from the cutting waste slurry of crystalline silicon, comprising the following steps:

[0065] Step 1, preparation before cutting

[0066] (1) The cutting wire of the multi-wire cutting machine adopts electroplated diamond wire;

[0067] (2) The holding material of crystalline silicon adopts epoxy resin board;

[0068] Step 2, waste slurry treatment

[0069] (1) Cut crystalline silicon with a multi-wire cutting machine, collect the cutting waste slurry, the composition and mass percentage of the cutting waste slurry are: 50% water-based cooling liquid, 47% silicon powder, and 1.5% metal impurities , 1.5% small diamond particles;

[0070] (2) Add 12kg of polyacrylamide to 600kg of diamond wire cutting crystalline silicon waste slurry, settling and stratifying, the upper layer is the supernatant, and the lower layer is the sedimentation material, perform a solid-liquid separation, and the upper layer of the supernatant...

Embodiment 3

[0075] A method for reclaiming high-purity silicon powder from the cutting waste slurry of crystalline silicon, comprising the following steps:

[0076] Step 1, preparation before cutting

[0077] (1) The cutting wire of the multi-wire cutting machine adopts resin diamond wire;

[0078] (2) The holding material of crystalline silicon adopts graphite plate;

[0079] Step 2, waste slurry treatment

[0080] (1) Cut crystalline silicon with a multi-wire cutting machine, collect the cutting waste slurry, the composition and mass percentages of the cutting waste slurry are: 50% water-based cooling liquid, 45% silicon powder, and 2% metal Impurities, 3% small diamond particles;

[0081] (2) Add 15kg of polyethyleneimine to 650kg of diamond wire cut crystalline silicon waste slurry, settling and stratifying, the upper layer is the supernatant, and the lower layer is the sedimentation material, perform a solid-liquid separation, and the supernatant of the upper layer returns to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com