Combined process for recycling organisms in PTA (Purified Terephthalic acid) refining waste water

A technology for refining wastewater and combining processes, applied in the separation/purification of carboxylic acid compounds, natural water treatment, heating water/sewage treatment, etc., can solve problems such as reduced operability, achieve good extraction effect, reduce water consumption, The effect of high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

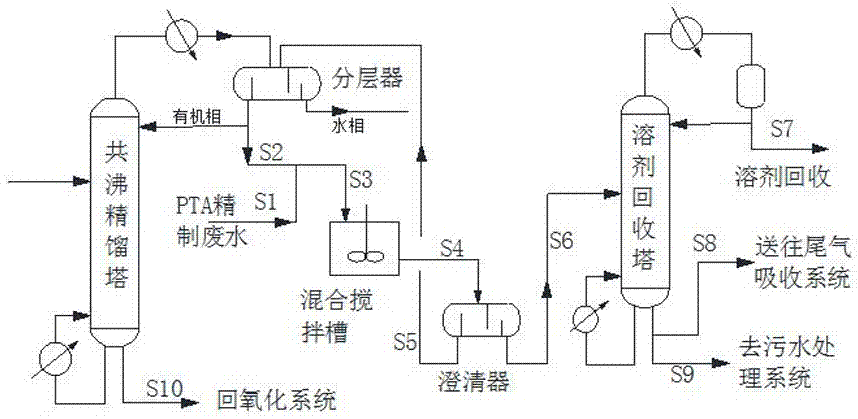

[0029] The technological process adopted in this embodiment is as follows figure 1 shown.

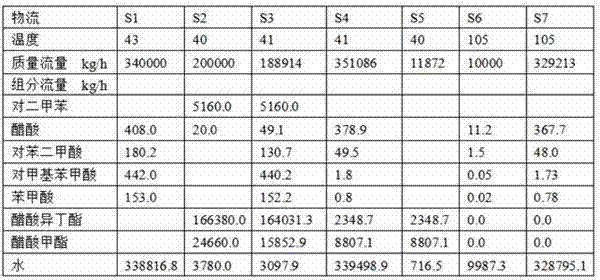

[0030] PTA refined wastewater S1 (340,000kg / hr) is cooled to 40 degrees after being cooled by a heat exchanger, and mixed with a stream S2 drawn from the organic return pipe of the azeotropic distillation tower. The volume ratio of S2 and S1 is 0.69. After being mixed by a pipeline mixer, S3 is sent to a mixing and stirring tank for single-stage extraction. The residence time of S3 in the mixing and stirring tank is 15min, and then sent to the clarifier for static stratification, and the residence time is 25min. The organic phase S5 from the clarifier is directly returned to the stratifier at the top of the azeotropic distillation column, and the organic matter (organic carboxylic acids such as benzoic acid, p-toluic acid, and terephthalic acid) in the wastewater is refluxed from the organic phase with the water agent The port enters the azeotropic distillation tower, and then these e...

Embodiment 2

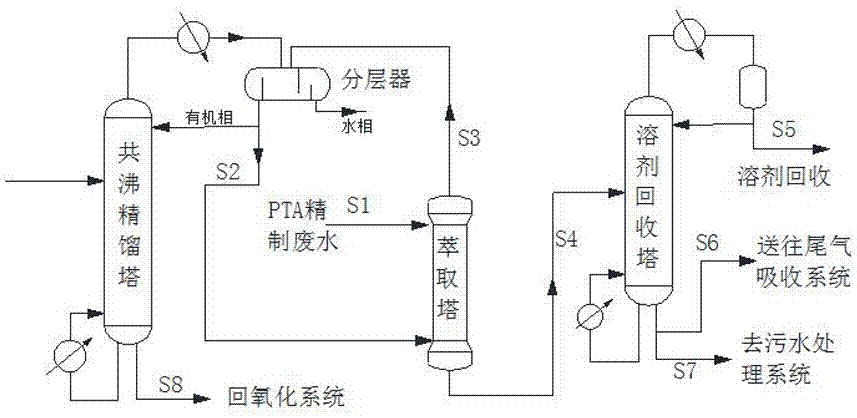

[0036] The technological process adopted in this embodiment is as follows figure 2 shown.

[0037] PTA refined wastewater S1 (340000kg / hr) is cooled to 40 degrees after being cooled by a heat exchanger, and enters the extraction tower from the upper feed port, and a stream S2 is drawn from the organic return pipe of the azeotropic distillation tower, and the stream S2 enters the extraction tower In the lower part, the volume ratio of S2 to S1 is 0.69. The theoretical stages of the extraction tower are 3 stages. The organic phase S3 from the top of the extraction tower is directly returned to the stratifier at the top of the azeotropic distillation tower. The reflux port enters the azeotropic rectification tower, and then these extracted organic substances are extracted from the bottom of the azeotropic rectification tower S8 together with acetic acid, and return to the oxidation system.

[0038] The aqueous phase S4 from the bottom of the extraction tower is sent to the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com