Synthesis technology of vidarabine monophosphate

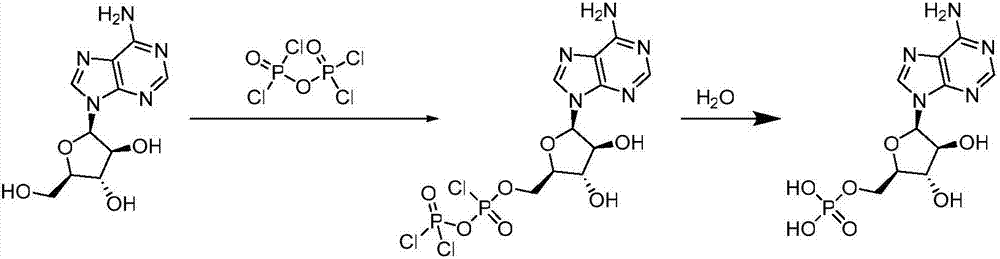

A technology for vidarabine monophosphate and vidarabine monophosphate crude products, which is applied in the field of medicine and can solve the problems of high toxicity, high price, and high impurity content of pyridine, and achieve easy control of the process and high product purity and yield , the effect of low impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Under the protection of nitrogen, add β-D- vidarabine (10g) and 250mL triethyl phosphate into the reaction flask, slowly add a mixed solution of pyrophosphoryl chloride 5.70mL and dichloromethane (20mL) dropwise at -40°C , After the addition, keep the low temperature reaction at -40°C for 24h. Pour the reaction solution into 150mL of ice water, and stir and hydrolyze it in an ice-water bath for 1h, add 200mL of dichloromethane, stir for 20min, and separate the organic layer after standing for 30min, and extract the aqueous phase with dichloromethane (100mL×2) , to combine the organic layers. Take the water phase, add saturated NaOH solution dropwise to adjust the pH of the solution between 2.5-3, then add 500mL ethanol dropwise, stir and crystallize at room temperature, filter, wash, and dry to obtain a crude product with a yield of 106% and a purity of 98.2%.

Embodiment 2

[0025] Under the protection of nitrogen, add β-D- vidarabine (10g), triethyl phosphate 200mL in the reaction flask, and slowly add the mixed solution of pyrophosphoryl chloride 6.25mL and dichloromethane (20mL) dropwise at -30°C , After the addition, keep the low temperature reaction at -30°C for 24h. Pour the reaction solution into 150mL of ice water, and stir and hydrolyze it in an ice-water bath for 1h, add 200mL of dichloromethane, stir for 20min, and separate the organic layer after standing for 30min, and extract the aqueous phase with dichloromethane (100mL×2) , to combine the organic layers. Take the water phase, add saturated NaOH solution dropwise to adjust the pH of the solution between 2.5-3, then add 500mL ethanol dropwise, stir and crystallize at room temperature, filter, wash, and dry to obtain a crude product with a yield of 101% and a purity of 98.1%.

Embodiment 3

[0027] Under the protection of nitrogen, add β-D- vidarabine (10g) and 180mL triethyl phosphate into the reaction flask, slowly add the mixed solution of pyrophosphoryl chloride 5.70mL and dichloromethane (20mL) dropwise at -20°C , After the addition, keep the low temperature reaction at -20°C for 24h. Pour the reaction solution into 150mL of ice water, and stir and hydrolyze it in an ice-water bath for 1h, add 200mL of dichloromethane, stir for 20min, and separate the organic layer after standing for 30min, and extract the aqueous phase with dichloromethane (100mL×2) , to combine the organic layers. Take the water phase, add saturated NaOH solution dropwise to adjust the pH of the solution between 2.5-3, then add 500mL ethanol dropwise, stir and crystallize at room temperature, filter, wash, and dry to obtain a crude product with a yield of 101% and a purity of 98.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com