Acidophilus thiobacillus and its method for treating mine acid wastewater and recovering iron resources

A technology of mine acid waste water and acid thiobacillus, applied in the field of microorganisms, can solve the problems of large amount of slag, secondary pollution, inability to recover waste water iron and other valuable metals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

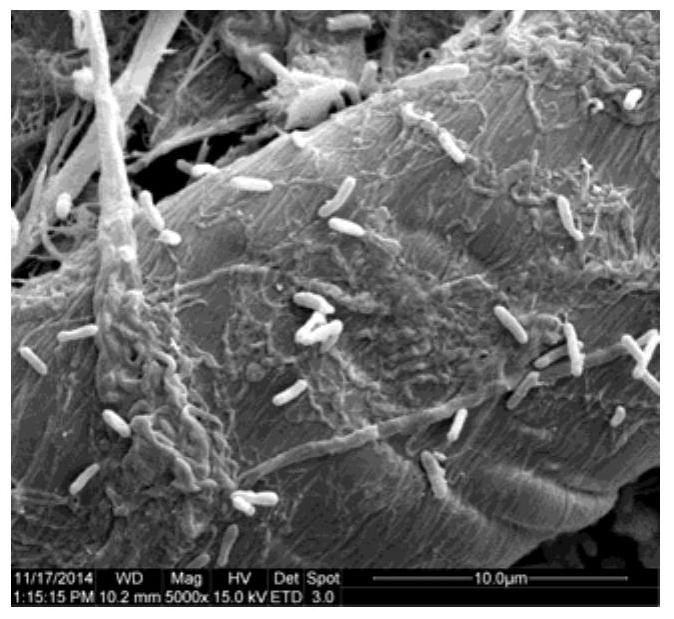

Image

Examples

Embodiment 1

[0032] Example 1 Acquisition and Identification of Acidophilus Thiobacillus

[0033] The obtaining method of acidic thiobacillus acidophilus provided by the invention is:

[0034] 1) Add 0.3g of yeast powder to 100mL of the water sample containing the acidic thiobacillus acidophilus, enrich and culture at 30°C with gentle shaking at 100rpm for 1 week, and use a microscope to detect the growth of the bacteria; the water sample is taken from Jiangxi De Xing copper mine copper-containing acid wastewater. Bacteria grow to measure the absorbance value of the bacterial culture solution at 600nm, if the obtained OD600 value is between 0.6-0.8.

[0035] 2) Filter the bacteria in the above culture solution by membrane filtration, and wash the bacteria with 20 mL of sterile water. Inoculate multiple 100mL enrichment media with 5% inoculum amount, culture at 45°C, and set no inoculation control (CK). The growth of bacteria was observed after two weeks of culture on a shaker at 100rpm....

Embodiment 2

[0039] Example 2 Treatment of Mine Acidic Wastewater and Recovery of Iron Resources

[0040] 1) The acid wastewater from the Dexing Copper Mine in Jiangxi is passed into a biological oxidation reactor, and the biological oxidation reactor is filled with commercially available soft packing for water treatment.

[0041] The wastewater quality is as follows: pH2.3; Cu 2+ : 220mg / L, total iron ion concentration: 1480mg / L.

[0042] 2) Inoculate the identified bacterial species of Acidophilus thiobacillus into the enrichment medium, and culture it on a shaker at 45°C at 100rpm until the bacterial concentration is 10 8 each / mL; then inoculate the bacterial solution into the biooxidation reactor with an inoculum volume of 3L / m 3 .

[0043] The biooxidation reactor used is a conventional packed biofilm reactor with air aeration at the bottom, and the treatment time is 1 hour.

[0044] 3) After the reaction, the effluent was passed into the solid-liquid separation reactor, the pH wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com