A method for efficient recovery of valuable metals from zinc leaching slag

A technology for leaching slag of valuable metals and zinc, which is applied in the field of zinc smelting, can solve the problem of low efficiency in metal comprehensive recovery, achieve the effects of reducing construction investment and production and operation costs, significant economic benefits, and short separation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

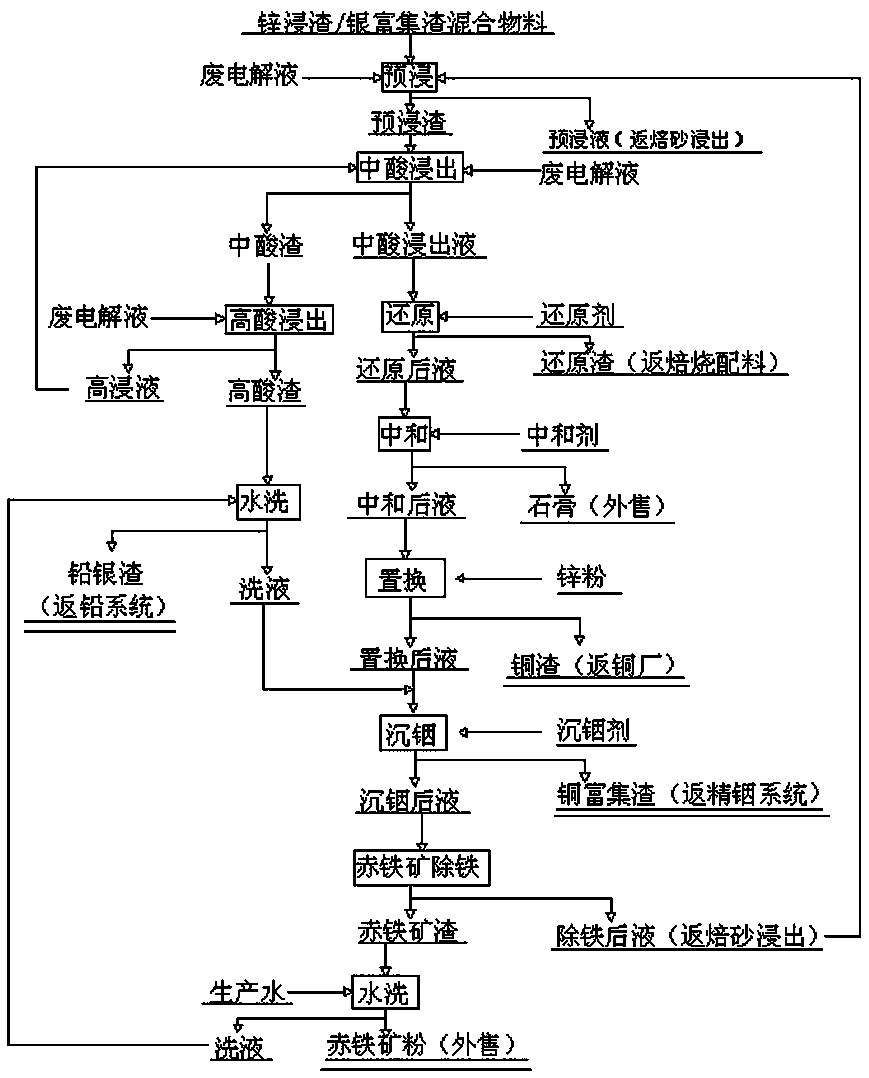

Image

Examples

Embodiment 1

[0035] Mix 19 tons of high copper and silver zinc leaching slag containing 10% zinc, 15% iron, 0.5% copper, 0.01% indium, and 0.005% silver with 1 ton of silver enriched slag containing 20% zinc and 0.15% silver. Sulfuric acid 150g / l, zinc-containing 40g / l fee electrolyte is used as the prepreg and the mixture is prepreg, the liquid-solid mass ratio is 3:1, the reaction is 0.5h, and 17.6 tons of prepreg slag and prepreg liquid are obtained. After prepreg The liquid enters the calcine leaching process of the main system; add the electrolytic solution containing 150g / l sulfuric acid and 40g / l zinc to the prepreg slag produced in the prepreg process for medium acid leaching. The weight ratio of liquid to solid is 4:1. The temperature is 65℃, the reaction time is 6h, and the end point acidity is 50g / l. After the reaction, 9.16 tons of acid slag is obtained. The acid slag contains 8% zinc, 8% iron, 0.2% copper, and 0.05% silver. The intermediate acid Liquid zinc 45 g / l, acid 50g / l...

Embodiment 2

[0037] Mix 10 tons of high copper and silver zinc leaching slag containing 25% zinc, 40% iron, 3% copper, 0.05% indium, and 0.06% silver with 10 tons of silver enriched slag containing 25% zinc and 1% silver. Sulfuric acid 200g / l, zinc-containing 60g / l fee electrolyte as prepreg and mixture prepreg, liquid-solid mass ratio 5:1, reaction 1h, get 17 tons of prepreg slag and prepreg liquid, after prepreg liquid Enter the calcine leaching process of the main system; add the electrolytic solution containing 200g / l sulfuric acid and 60g / l zinc to the prepreg slag produced in the prepreg process for medium acid leaching, liquid-solid weight ratio 6:1, reaction temperature 75℃, the reaction time is 6h, the end point acidity is 70g / l, and 8.5 tons of acid residues are obtained after the reaction. These acid residues contain 16% zinc, 15% iron, 0.4% copper, and 0.5% silver. Acid solution zinc 70 g / l, acid content 70 g / l, ferric iron content 45 g / l; medium acid slag enters the high acid l...

Embodiment 3

[0039] The liquid after iron removal from the hematite removal process contains 95 g / l zinc, 3.5 g / l iron, 42 g / l acid, and a temperature of 93.5℃. Add 18.5% zinc, 22.5% iron and 0.9 copper. 8 tons of zinc leaching slag containing 80% by weight of indium, 0.032%, and 0.032% of silver, and 2 tons of silver-rich slag containing 23.8% by weight of zinc and 0.42% by weight of silver and 20% by weight, liquid-solid ratio of 3:1, reaction In 1h, 8.8 tons of prepreg residue and post-pre-preg liquid are obtained. The post-pre-preg liquid enters the main system calcine leaching process. The acid-containing 128 g / l high-acid solution from the high-acid leaching process is added to the prepreg slag produced in the pre-preg process. The acid leaching is carried out, the liquid-to-solid ratio is 4:1, the reaction temperature is 75℃, the reaction time is 6h, and the end point acidity is 66g / l. The 4.58 tons of acid residue after the reaction contains 8.2% zinc, 8.5% iron, and 0.23% copper. S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com