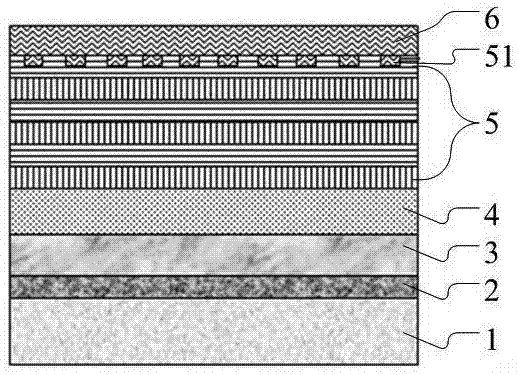

Diesel engine part surface multilayer wear-resisting anti-friction thin film and preparing method thereof

A technology for diesel engines and parts, applied in the field of multi-layer films, can solve the problems of low life expectancy, low friction, and difficulty in meeting high load capacity, and achieve the effects of increasing service life, improving service life and improving surface performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1 Taking the multi-layer wear-resistant and friction-reducing film on the surface of a diesel engine plunger as an example

[0028] (1) Chemical cleaning. Use petroleum ether, acetone, and alcohol to ultrasonically clean the base material of the diesel engine plunger, and the ultrasonic time for each solvent is 5 minutes.

[0029] (2) Heating and vacuuming. Ensure that the film is deposited within a certain temperature and vacuum range, the heating temperature is 160 °C, and the vacuum range is 2×10 -3 Pa.

[0030] (3) Plasma source (glow discharge) bombardment cleaning. Introduce argon gas into the vacuum chamber, turn on the plasma source to bombard and clean the substrate surface, and remove the attachments on the substrate surface. The flow rate of argon gas is 150 sccm, the plasma source current is 60A, the substrate bias voltage is 500V, and the bombardment time is 30min. .

[0031] (4) Deposit a Cr layer. Introduce argon gas, turn on the magnetron s...

Embodiment 2

[0037] Example 2 Taking the multi-layer wear-resistant and friction-reducing film on the surface of the tappet washer of a diesel engine as an example

[0038] (1) Chemical cleaning. Use petroleum ether, acetone, and alcohol to ultrasonically clean the base material of the diesel engine tappet gasket, and the ultrasonic time for each solvent is 5 minutes.

[0039] (2) Heating and vacuuming. Ensure that the film is deposited within a certain temperature and vacuum range, the heating temperature is 160 °C, and the vacuum range is 2×10 -3 Pa.

[0040] (3) Plasma source bombardment cleaning. Introduce argon gas into the vacuum chamber, turn on the plasma source to bombard and clean the substrate surface, and remove the attachments on the substrate surface. The flow rate of argon gas is 150 sccm, the plasma source current is 60A, the substrate bias voltage is 500V, and the bombardment time is 30min. .

[0041] (4) Deposit a Cr layer. Introduce argon gas, turn on the magnetron s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com