High viable count natto solid drink and preparation method thereof

A technology for high-viability natto and solid beverages is applied in the directions of sugar-containing food ingredients, oligosaccharide-containing food ingredients, and food ingredients as taste modifiers, etc., and achieves a simple preparation method, a sweet and sour taste, and high natto activity. The effect of bacterial count

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

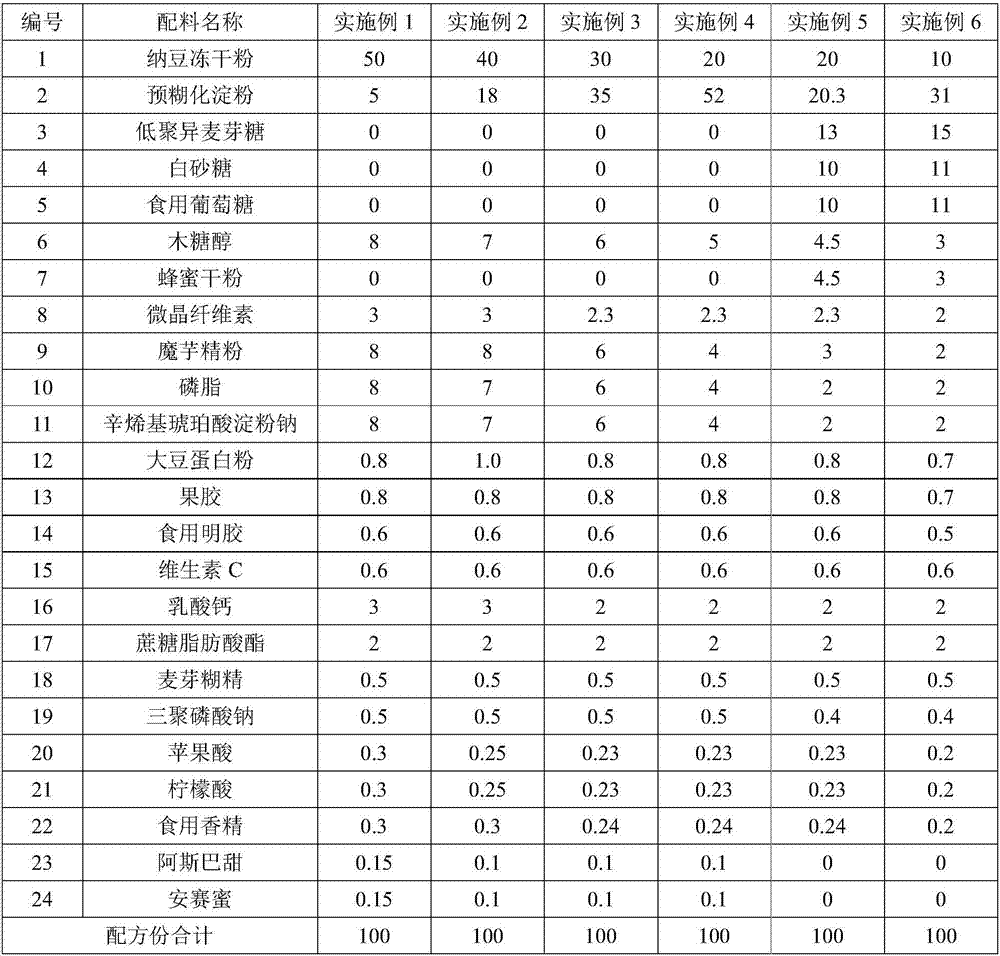

Embodiment 1

[0069] 1) Preparation of natto premix by mixing ingredients at one time: First, weigh 50 parts of natto freeze-dried powder, 3 parts of microcrystalline cellulose, 8 parts of konjac powder, 0.8 part of soybean protein powder, and pectin according to the mass formula ratio. 0.8 parts, 0.6 parts of edible gelatin, 2 parts of sucrose fatty acid esters, 0.5 parts of sodium tripolyphosphate, and then pre-mixed once by stirring, then added the mixture of 8 parts of phospholipids and 8 parts of starch sodium octenyl succinate, and passed Stir for secondary premixing, and finally mix the raw and auxiliary materials evenly through a 16-mesh oscillating granulator to make a natto premix.

[0070] 2) Secondary ingredients are mixed to prepare natto mixture: first, according to the mass formula ratio, weigh 5 parts of pregelatinized starch, 0 parts of isomaltooligosaccharide, 0 part of white granulated sugar, 0 part of edible glucose, and 8 parts of xylitol , 0.6 parts of vitamin C, 3 par...

Embodiment 2

[0082] 1) Preparation of natto premix by mixing ingredients at one time: First, weigh 40 parts of natto freeze-dried powder, 3 parts of microcrystalline cellulose, 8 parts of konjac powder, 1 part of soybean protein powder, and pectin according to the mass formula ratio. 0.8 parts, 0.6 parts of edible gelatin, 2 parts of sucrose fatty acid esters, 0.5 parts of sodium tripolyphosphate, and then pre-mixed once by stirring, then added 7 parts of phospholipids and 7 parts of starch sodium octenyl succinate, and passed Stir for secondary premixing, and finally mix the raw and auxiliary materials evenly through a 16-mesh oscillating granulator to make a natto premix.

[0083] 2) Secondary ingredients are mixed to prepare natto mixture: first, according to the mass formula ratio, weigh 18 parts of pregelatinized starch, 0 parts of isomaltooligosaccharide, 0 part of white sugar, 0 part of edible glucose, and 7 parts of xylitol , 0.6 parts of vitamin C, 3 parts of calcium lactate, 0.5 ...

Embodiment 3

[0095] 1) Preparation of natto premix by mixing ingredients at one time: First, weigh 30 parts of natto freeze-dried powder, 2.3 parts of microcrystalline cellulose, 6 parts of konjac powder, 0.8 part of soybean protein powder, and pectin according to the mass formula ratio. 0.8 parts, 0.6 parts of edible gelatin, 2 parts of sucrose fatty acid esters, 0.5 parts of sodium tripolyphosphate, and then pre-mixed once by stirring, and then added the mixture of 6 parts of phospholipids and 6 parts of starch sodium octenyl succinate, and then passed Stir for secondary premixing, and finally mix the raw and auxiliary materials evenly through a 16-mesh oscillating granulator to make a natto premix.

[0096] 2) Preparation of natto mixture by mixing secondary ingredients: first, weigh 35 parts of pregelatinized starch, 0 part of isomaltooligosaccharide, 0 part of white granulated sugar, 0 part of edible glucose and 6 parts of xylitol according to the mass formula ratio , 0.6 parts of vit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com