High-efficiency carbon self-doped graphite phase carbon nitride visible light photocatalyst, and preparation method and application thereof

A graphitic carbon nitride, self-doping technology, applied in physical/chemical process catalysts, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as low hydrogen production efficiency, achieve inhibition of recombination, simple preparation process, absorption The effect of improved range and absorption strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Preparation of high-efficiency carbon self-doped graphite phase carbon nitride catalyst for visible light.

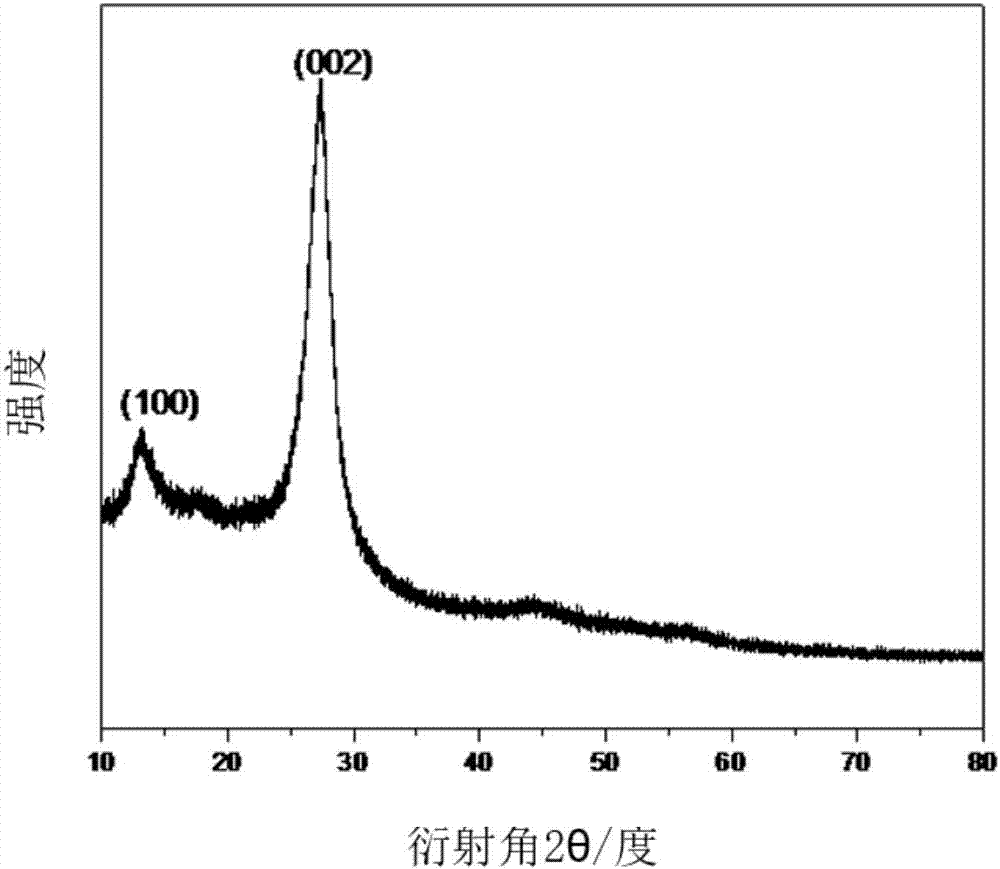

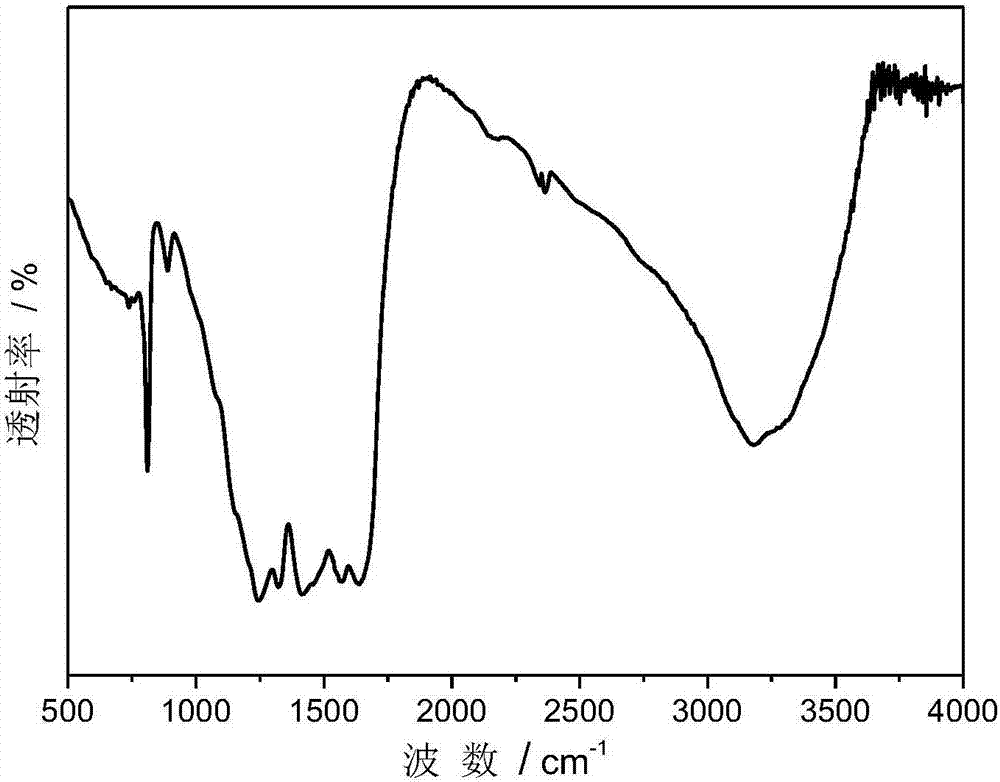

[0026] Add melamine (2g) and 2,4,6-triaminopyrimidine (0.03g) into ethanol (6mL), stir evenly, evaporate the ethanol to dryness, and grind thoroughly to obtain a mixture. The above mixture was placed under vacuum conditions at 100°C for 12h, and then placed in a muffle furnace for heat treatment at 550°C for 4h to obtain a high-efficiency carbon self-doped graphite phase carbon nitride catalyst (0.90g), and its X-ray diffraction pattern is as follows figure 1 As shown, its Fourier transform infrared spectrum is shown as figure 2 shown.

[0027] Depend on figure 1 It can be seen that the two obvious diffraction peaks at 13.0° and 27.4° belong to the (100) and (002) crystal planes of graphitic carbon nitride, respectively. Depend on figure 2 It can be seen that at 810cm -1 and 1200~1600cm -1 The peaks at are assigned to the breathing vibration of...

Embodiment 2

[0028] Example 2: Preparation of high-efficiency carbon self-doped graphite phase carbon nitride catalyst for visible light.

[0029] Add melamine (2 g) and 2-amino-4,6-dihydroxypyrimidine (0.02 g) into ethanol (10 mL), stir evenly, evaporate the ethanol to dryness, and grind thoroughly to obtain a mixture. The above mixture was placed under vacuum at 80°C for 10h, and then placed in a muffle furnace for heat treatment at 530°C for 5h to obtain a highly efficient carbon self-doped graphite phase carbon nitride catalyst (0.88g).

Embodiment 3

[0030] Example 3: Preparation of high-efficiency carbon self-doped graphite phase carbon nitride catalyst for visible light.

[0031] Add melamine (2g) and 2-amino-4,6-dihydroxypyrimidine (0.04g) into water (30mL), stir evenly, evaporate the water to dryness, and grind thoroughly to obtain a mixture. The above mixture was placed under vacuum conditions at 120°C for 24h, and then placed in a muffle furnace for heat treatment at 520°C for 6h to obtain a highly efficient carbon self-doped graphite phase carbon nitride catalyst (0.87g).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com