Additive capable of releasing negative oxygen ions and preparation method of additive

A technology of negative oxygen ions and additives, which is applied in the field of additives that can release negative oxygen ions and its preparation, can solve the problems of high raw materials and energy consumption, complicated processes, high prices, etc., and achieves enhanced immunity, high purity, and lower blood pressure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

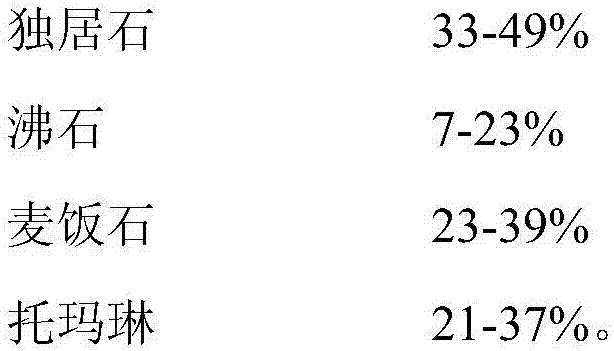

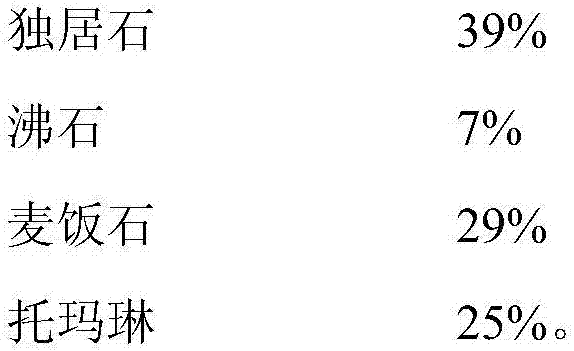

[0036]Composition of raw materials: 39% of monazite, 7% of zeolite, 29% of medical stone, 25% of tourmaline, calculated by weight percentage. All raw materials are processed according to the following process steps: (1) water power desilting and impurity removal; (2) drying and dehydration; (3) coarse crushing; (4) ultrafine grinding; (6) Mixing ingredients according to the above mass percentages to obtain a powder mixture, and then using a surface active agent sucrose ester to perform surface modification and activation treatment on the powder mixture by a surface physical coating method to obtain final product.

Embodiment 2

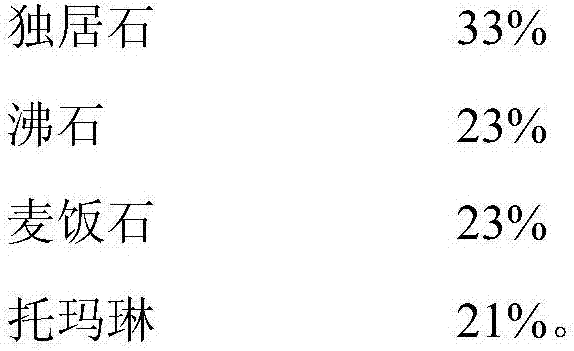

[0038] Raw material composition: 33% of monazite, 23% of zeolite, 23% of medical stone, 21% of tourmaline, calculated by weight percentage. All raw materials are processed according to the following process steps: (1) water power desilting and impurity removal; (2) drying and dehydration; (3) coarse crushing; (4) ultrafine grinding; (6) Mixing ingredients according to the above mass percentages to obtain a powder mixture, and then using a surface active agent sucrose ester to perform surface modification and activation treatment on the powder mixture by a surface physical coating method to obtain final product.

Embodiment 3

[0040] Composition of raw materials: 45% of monazite, 8% of zeolite, 25% of medical stone, 22% of tourmaline, calculated by weight percentage. All raw materials are processed according to the following process steps: (1) water power desilting and impurity removal; (2) drying and dehydration; (3) coarse crushing; (4) ultrafine grinding; (6) Mixing ingredients according to the above mass percentages to obtain a powder mixture, and then using a surface active agent sucrose ester to perform surface modification and activation treatment on the powder mixture by a surface physical coating method to obtain final product.

[0041] The additives prepared in Examples 1-3 are tested to release 2050-25000 negative oxygen ions per gram per second, and the far-infrared emission wavelength is 2-18um. The emissivity of the additive to far-infrared is more than 90%; the negative oxygen ions produced in the additive have high activity, have a strong redox effect, and can destroy the activity of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com