Method for detecting content of chloride in water

A determination method and chloride technology, which are applied in the direction of chemical analysis, measuring devices, and preparation of test samples, etc., can solve problems such as the inability to grasp the changes of chloride in the condensed water of the device, corrosion of low-temperature parts, and large turbidity, etc. To achieve the effect of filling chlorides that cannot be accurately detected, improving accuracy, and improving the level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

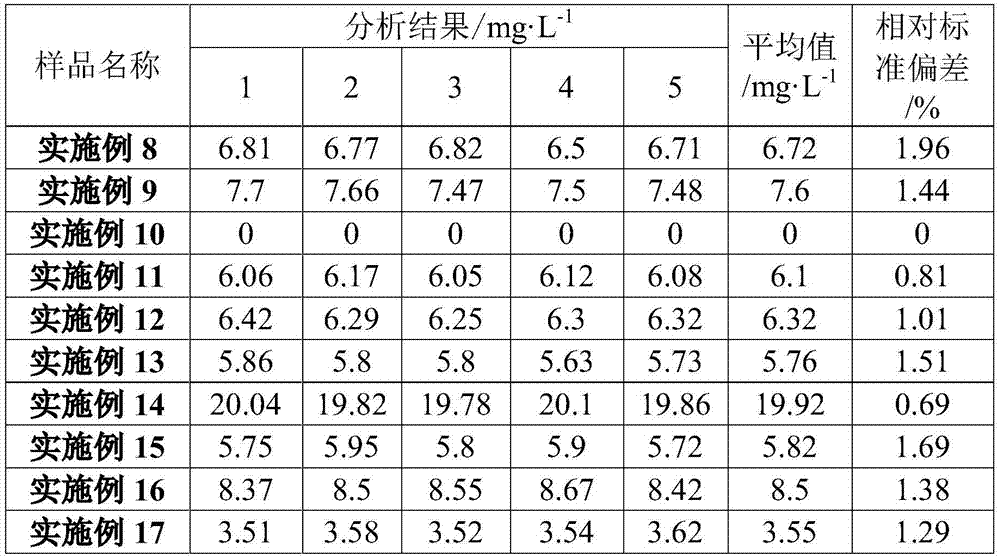

Embodiment 1

[0022] Take 50mL of sodium chloride standard solution with a concentration of 10mg / L and place it in a 250mL beaker, adjust the water sample to pH 8-9 with 1mol / L sodium hydroxide solution, heat it on an electric furnace until the steam generated by heating no longer Turn wet pH paper blue. Then use 10% nitric acid to adjust the water sample to a pH value of 2 to 3, and continue heating on the electric furnace until the steam generated by heating does not blacken the wet lead acetate test paper. Add 1mL of 30% hydrogen peroxide, continue heating for 2 minutes, add deionized water in time to prevent drying during heating, cool the solution to room temperature, then transfer to a titration cup, adjust the volume of the water sample to 50mL with deionized water . Add 1 drop of 0.1% bromophenol blue indicator solution to the treated water sample, the water sample is dark yellow, adjust the color of the water sample to just yellow with 1mol / L sodium hydroxide solution, shake well,...

Embodiment 2

[0024] Take 50mL of sodium chloride standard solution with a concentration of 20mg / L and put it in a 250mL beaker, adjust the water sample to a pH value of 8-9 with 1mol / L sodium hydroxide solution, and heat it on an electric furnace until the steam generated by heating no longer Turn wet pH paper blue. Then use 10% nitric acid to adjust the water sample to a pH value of 2 to 3, and continue heating on the electric furnace until the steam generated by heating does not blacken the wet lead acetate test paper. Add 1mL of 30% hydrogen peroxide, continue heating for 2 minutes, add deionized water in time to prevent drying during heating, cool the solution to room temperature, then transfer to a titration cup, adjust the volume of the water sample to 50mL with deionized water . Add 1 drop of 0.1% bromophenol blue indicator solution to the treated water sample, the water sample is dark yellow, adjust the color of the water sample to just yellow with 1mol / L sodium hydroxide solution...

Embodiment 3

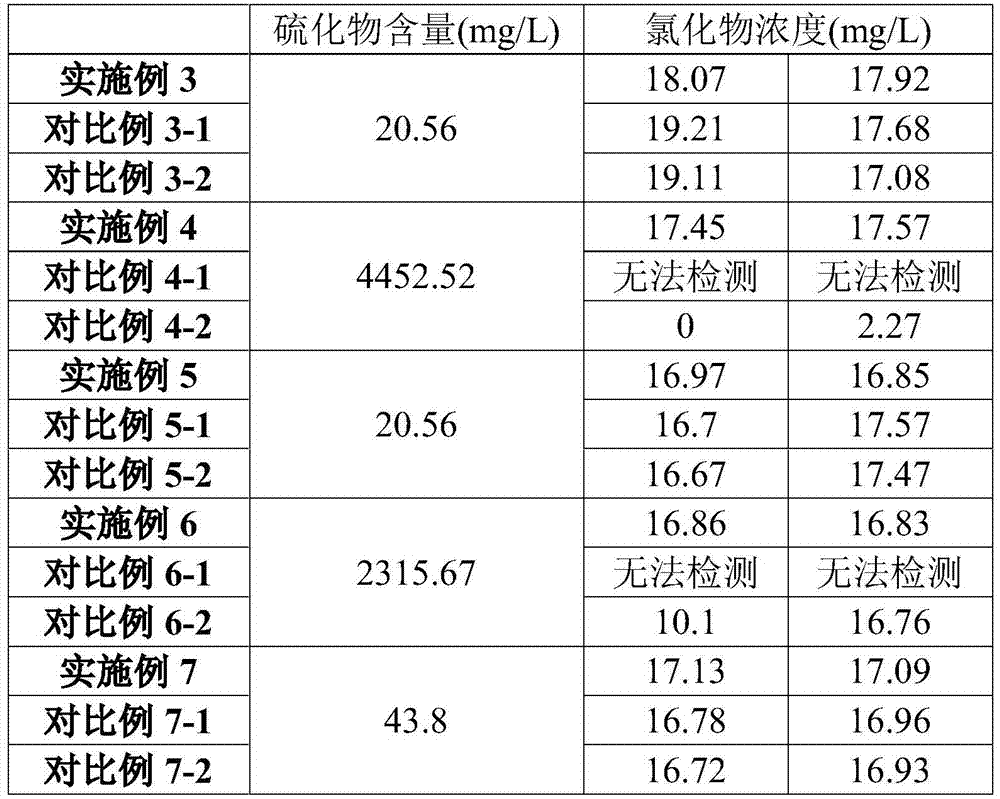

[0026] Take 20mL of the water sample to be tested with a sulfide content of 20.56mg / L and place it in a 250mL beaker, add 4mL of a sodium chloride standard solution with a concentration of 100mg / L to it, and adjust the total volume to about 50mL with deionized water. Use 1mol / L sodium hydroxide solution to adjust the water sample to a pH value of 8-9, and heat it on an electric furnace until the steam generated by heating no longer turns the wet pH test paper blue. Then use 10% nitric acid to adjust the water sample to a pH value of 3 to 4, and continue heating on the electric furnace until the steam generated by heating does not blacken the wet lead acetate test paper. Add 1mL of 30% hydrogen peroxide, continue heating for 3 minutes, add deionized water in time during the heating process to prevent drying, cool the solution to room temperature, then transfer to a titration cup, adjust the volume of the water sample with deionized water 50mL. Add 1 drop of 0.1% bromophenol bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com