Indium tin oxide transparent electrode-based opposed-contact photoconductive switch and fabrication method thereof

An indium tin oxide and photoconductive switch technology, applied in the field of microelectronics, can solve the problems of low energy density triggering, limited laser incident area, laser energy attenuation, etc., to achieve flexible and convenient design, reduce design difficulty, and low energy Density-triggered effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

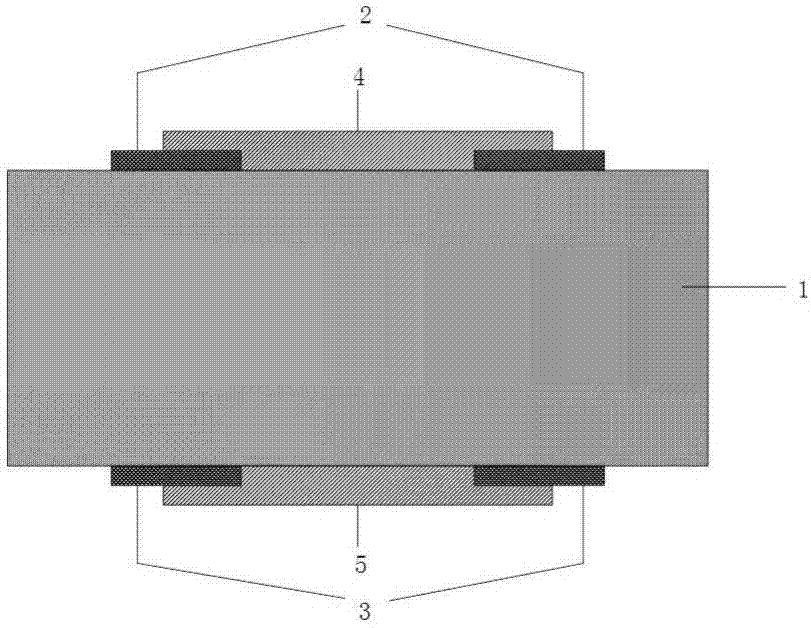

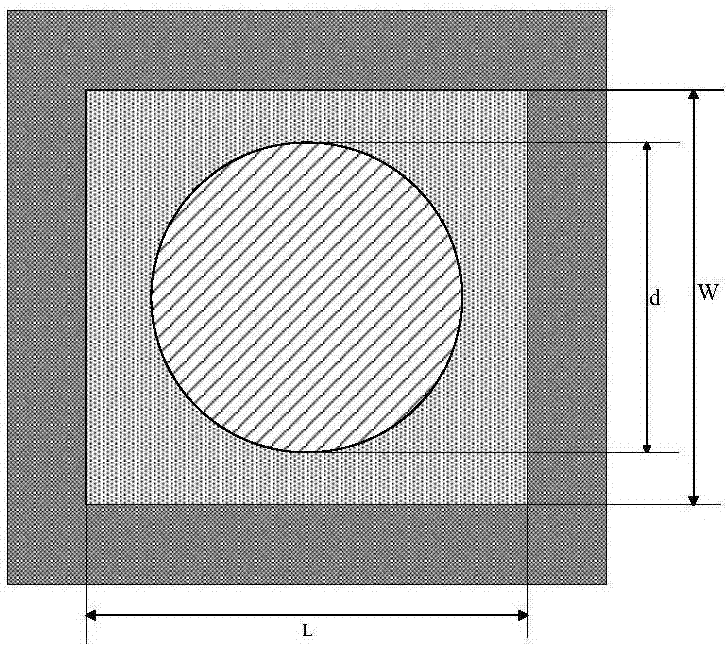

[0033] Example 1, the diameter d of the bottom surface of the upper film electrode and the lower film electrode is both 6 mm, the thickness is 0.5 μm, the thickness of the upper ohmic contact electrode and the lower ohmic contact electrode is 0.63 μm, and the transverse width and longitudinal width are 7 mm. Electrode out-of-plane photoconductive switch.

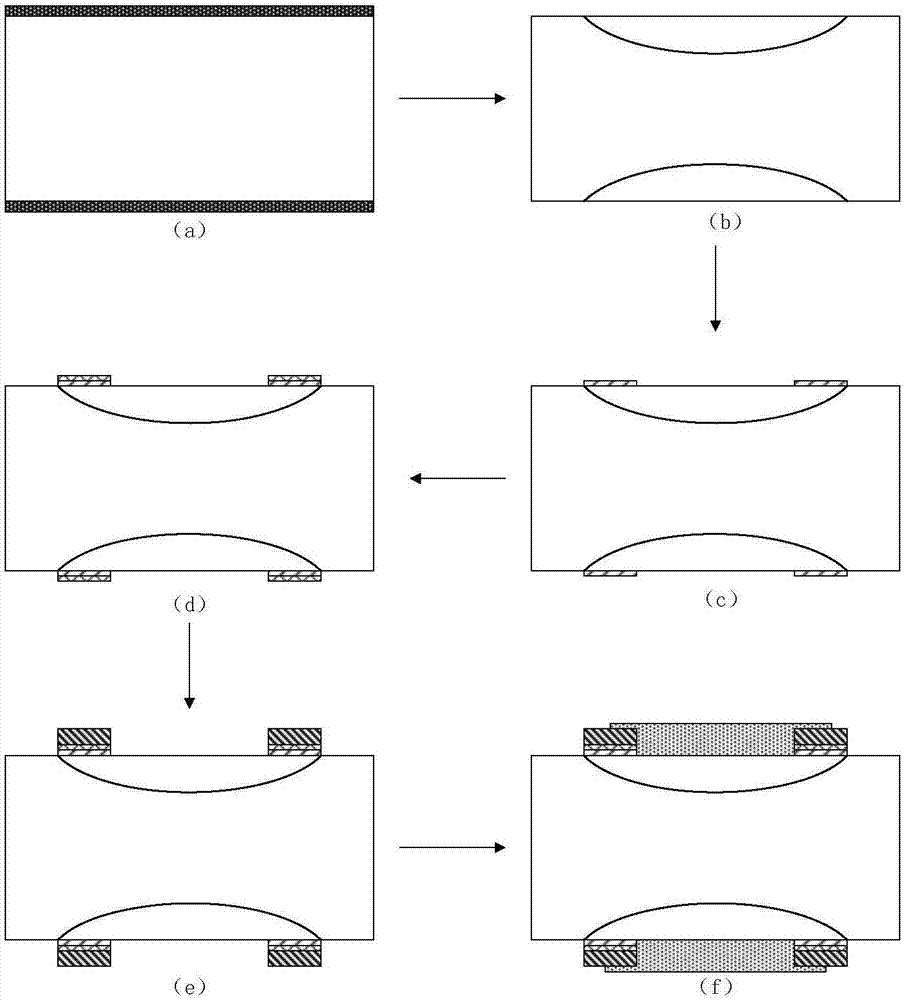

[0034] Step 1: Deposit barrier layers on the front and back of the vanadium-compensated 4H-SiC semi-insulating substrate sample.

[0035] Using the PECVD method to deposit silicon dioxide with a thickness of 1 μm on the front and back of the rectangular parallelepiped silicon carbide substrate sample, as a barrier layer for ion implantation on the front and back of the substrate; image 3 a.

[0036] Step 2: Perform ion implantation on the front and back of the sample respectively.

[0037](2a) apply glue on the barrier layer on the front and back of the sample sheet respectively, use a photolithography plate to expose and...

Embodiment 2

[0053] Example 2, the diameter d of the bottom surface of the upper film electrode and the lower film electrode is both 7 mm, the thickness is 1.5 μm, the thickness of the upper ohmic contact electrode and the lower ohmic contact electrode is 1.165 μm, and the horizontal width and vertical width are 9 mm. Electrode out-of-plane photoconductive switch.

[0054] Step 1: Deposit barrier layers on the front and back of the vanadium-compensated silicon carbide semi-insulating substrate sample.

[0055] Using the PECVD method to deposit silicon dioxide with a thickness of 2.5 μm on the front and back of the rectangular parallelepiped silicon carbide substrate sample, as a barrier layer for ion implantation on the front and back of the substrate; image 3 a.

[0056] Step 2: Perform ion implantation on the front and back of the sample respectively.

[0057] 2.1) Apply glue on the barrier layer on the front and back of the sample respectively, etch the ion implantation window on the...

Embodiment 3

[0073] Example 3, the diameter d of the bottom surface of the upper film electrode and the lower film electrode is both 9 mm, the thickness is 3 μm, the thickness of the upper ohmic contact electrode and the lower ohmic contact electrode is 2.5 μm, and the transparent electrode with a horizontal width and a vertical width of 10 mm Different surface photoconductive switch.

[0074] Step A: The vanadium-compensated silicon carbide semi-insulating substrate is deposited on the front side and the back side respectively.

[0075] The PECVD method is used to deposit silicon dioxide with a thickness of 5 μm on the front and back of the rectangular parallelepiped silicon carbide substrate sample, as a barrier layer for ion implantation on the front and back of the substrate; image 3 a

[0076] Step B: performing ion implantation on the front and back of the sample respectively.

[0077](B1) Apply glue on the barrier layer on the front and back of the sample respectively, use a phot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com