Straw mushroom cultivation base material and preparation method thereof

A cultivation base material, straw mushroom technology, applied in the field of straw mushroom cultivation base material and its preparation, can solve the problems of low biotransformation rate of straw mushroom, influence on biotransformation rate, impact on yield of straw mushroom, etc., save labor time, shorten fermentation time, improved quality and yield effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

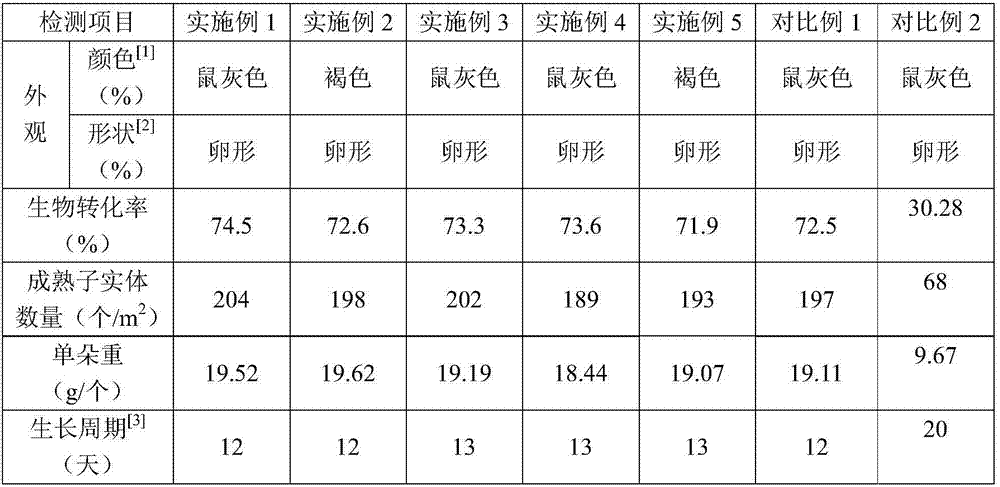

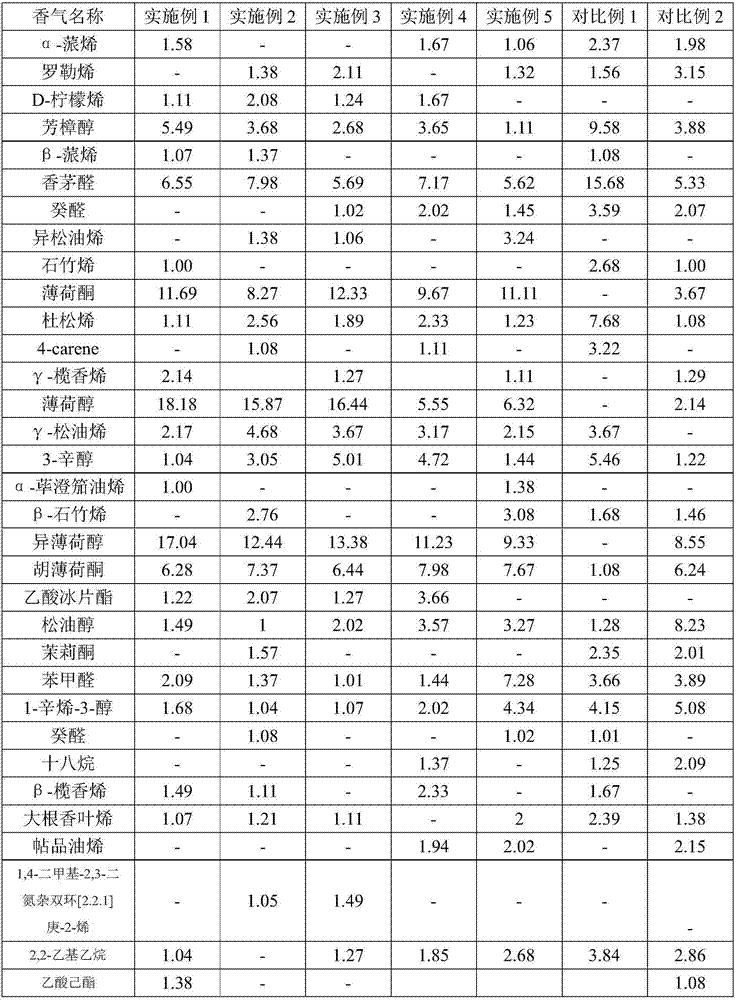

Examples

Embodiment 1

[0036] Embodiment 1 A kind of straw mushroom cultivation base material and its preparation method

[0037] Straw mushroom cultivation base material includes the following components by weight: dry mint 20, corn cob 25, apple branch 20, wheat bran 6, bean cake powder 5, tangerine peel 8, grape pomace 9, peanut shell 10, apple leaf 7, coconut bran 10 , sesame shell 5, rhamnolipid 0.2, sodium polyacrylate 5, expanded vermiculite 2, lime powder 20.

[0038] The method for preparing the above-mentioned straw mushroom cultivation base material, the steps are as follows:

[0039] (1) lime powder is dropped into the water of immersion pond, stir, obtain lime water, the weight ratio of lime powder and water is 8:100;

[0040] (2) Apple branches are crushed until the length is 1 to 5 mm, placed in the soaking pool of step (1), soaked for 4 days, taken out, rinsed with clear water, removed the lime powder on the surface, and set aside;

[0041] (3) crush the corn cob until the particle...

Embodiment 2

[0047] Embodiment 2 A kind of straw mushroom cultivation base material and its preparation method

[0048] Straw mushroom cultivation base material includes the following components by weight: dry mint 20, corn cob 25, apple branch 20, wheat bran 6, bean cake powder 5, tangerine peel 8, grape pomace 9, peanut shell 10, apple leaf 7, coconut bran 10 , sesame shell 5, rhamnolipid 0.2, sodium polyacrylate 5, expanded vermiculite 2, lime powder 20.

[0049] The method for preparing the above-mentioned straw mushroom cultivation base material, the steps are as follows:

[0050] (1) lime powder is dropped into the water of immersion pond, stir, obtain lime water, the weight ratio of lime powder and water is 7:100;

[0051] (2) Apple branches are crushed until the length is 1 to 5 mm, placed in the soaking pool of step (1), soaked for 3 days, taken out, rinsed with clear water, removed the lime powder on the surface, and set aside;

[0052] (3) Crush the corn cob until the particle...

Embodiment 3

[0058] Embodiment 3 A kind of straw mushroom cultivation base material and its preparation method

[0059] Straw mushroom cultivation base material includes the following components by weight: dry mint 20, corn cob 25, apple branch 20, wheat bran 6, bean cake powder 5, tangerine peel 8, grape pomace 9, peanut shell 10, apple leaf 7, coconut bran 10 , sesame shell 5, rhamnolipid 0.2, sodium polyacrylate 5, expanded vermiculite 2, lime powder 20.

[0060] The method for preparing the above-mentioned straw mushroom cultivation base material, the steps are as follows:

[0061] (1) lime powder is dropped into the water of immersion pool, stir, obtain lime water, the weight ratio of lime powder and water is 9:100;

[0062] (2) Apple branches are crushed until the length is 1 to 5, placed in the soaking pool of step (1), soaked for 5 days, taken out, rinsed with clear water, removed the lime powder on the surface, and set aside;

[0063] (3) crush the corn cob until the particle si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com