An acrylate modified polyurethane emulsion and a preparing method thereof

A technology of polyurethane emulsion and acrylate, which is applied in the direction of application, coating, ink, etc., can solve the problems of reducing the viscosity and stability of the system, and achieve the effects of improving water and moisture resistance, excellent effect, and increasing drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

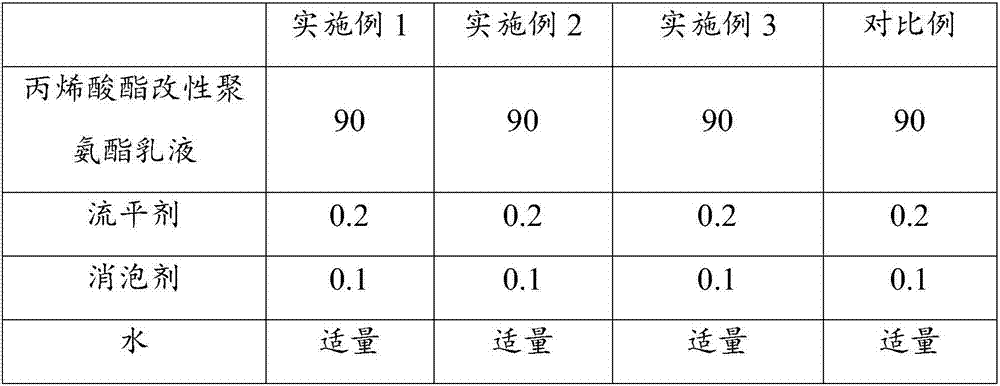

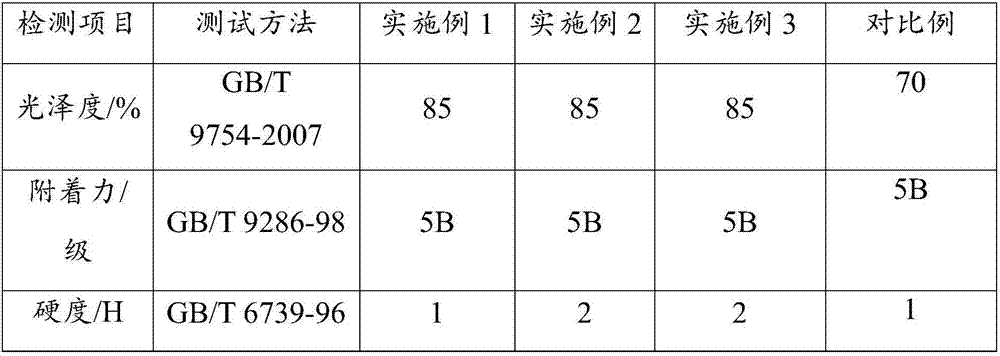

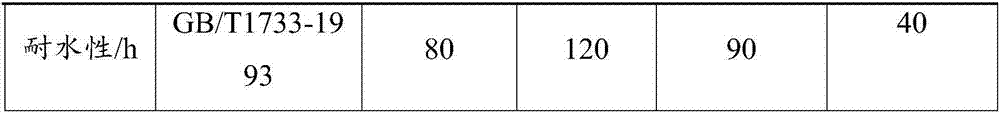

Embodiment 1

[0037] The preparation method of a kind of acrylate-modified polyurethane emulsion of the present embodiment comprises the steps:

[0038] 1) Mix 7 parts of isophorone diisocyanate, 1 part of DMPA (2,2-dimethylolpropionic acid), 0.5 parts of γ-(2,3-epoxypropoxy)propyltrimethoxysilane (KH560 ), 15 parts of 1000 molecular weight polyester diols were placed in a four-necked flask equipped with a mechanical stirrer, dropping funnel and reflux condenser, stirred for 1 hour, and DMPA was fully dispersed evenly;

[0039] 2) Add 0.02 parts of stannous octoate at 50°C (adding in three times, with an interval of 0.5h between each time) and keep the temperature not exceeding 55°C, raise the temperature to 80°C, stir for 6 hours, and rotate at a speed of 400-600rpm;

[0040] 3) Cool down to 75°C, add HEMA (hydroxyethyl methacrylate), stir and react at 75°C for 2 hours;

[0041] 4) Cool down to 60°C, add MMA (methyl methacrylate), BA (butyl acrylate), MA (methyl acrylate), and stir for 0....

Embodiment 2

[0047] The preparation method of a kind of acrylate-modified polyurethane emulsion of the present embodiment comprises the following steps:

[0048]1) Mix 7 parts of isophorone diisocyanate, 1 part of DMPA, 0.5 parts of γ-(2,3-epoxypropoxy)propyltrimethoxysilane (KH560), 15 parts of 1000 molecular weight polycarbonate diol Place in a four-neck flask equipped with a mechanical stirrer, dropping funnel and reflux condenser, and stir for 1 hour to fully disperse DMPA evenly;

[0049] 2) Add 0.02 parts of stannous octoate at 50°C (adding in three times, with an interval of 0.5h between each time) and keep the temperature not exceeding 55°C, raise the temperature to 80°C, stir for 6 hours, and rotate at a speed of 400-600rpm;

[0050] 3) Cool down to 75°C, add HEMA, stir and react at 75°C for 2 hours;

[0051] 4) Cool down to 60°C, add MMA, BA, MA, and stir for 0.5 hours to fully mix the acrylate monomer and polyurethane prepolymer;

[0052] 5) Lower the temperature to 40-50°C, a...

Embodiment 3

[0057] The preparation method of a kind of acrylate-modified polyurethane emulsion of the present embodiment comprises the following steps:

[0058] 1) Mix 7 parts of isophorone diisocyanate, 1 part of DMPA, 0.5 parts of γ-(2,3-epoxypropoxy)propyltrimethoxysilane (KH560), 15 parts of 1000 molecular weight polycaprolactone binary Alcohol was placed in a four-neck flask equipped with a mechanical stirrer, dropping funnel and reflux condenser, and stirred for 1 hour to fully disperse DMPA evenly;

[0059] 2) Add 0.02 parts of stannous octoate at 50°C (adding in three times, with an interval of 0.5h between each time) and keep the temperature not exceeding 55°C, raise the temperature to 80°C, stir for 6 hours, and rotate at a speed of 400-600rpm;

[0060] 3) Cool down to 75°C, add HEMA, stir and react at 75°C for 2 hours;

[0061] 4) Cool down to 60°C, add MMA, BA, MA, and stir for 0.5 hours to fully mix the acrylate monomer and polyurethane prepolymer;

[0062] 5) Lower the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com