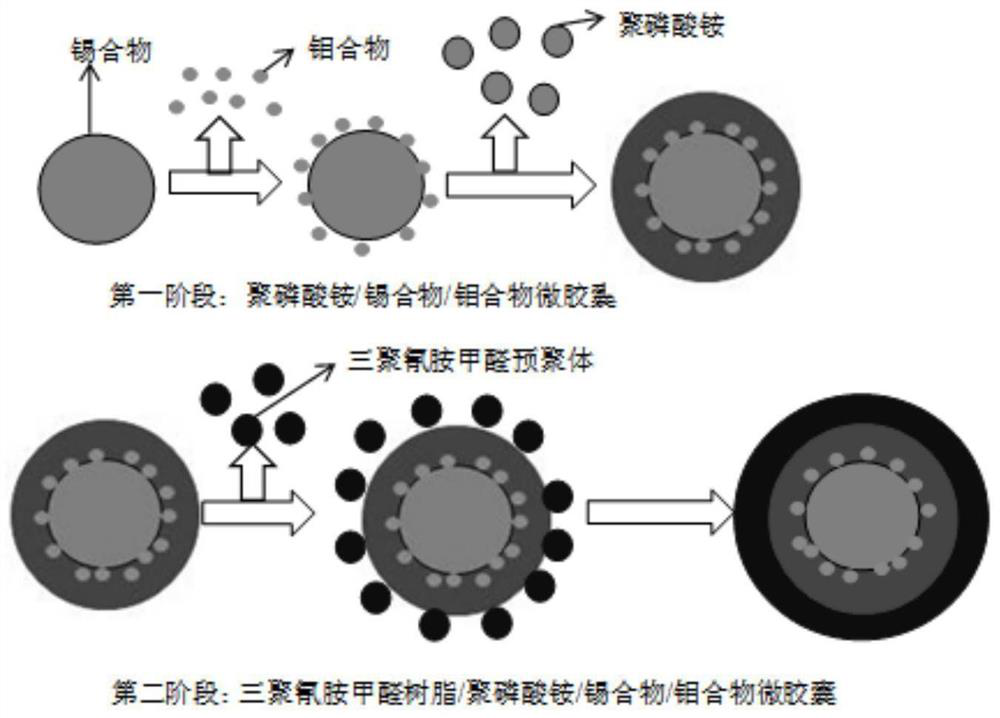

A kind of microcapsule flame retardant of high-efficiency environmental protection multi-layer structure and preparation method thereof

A multi-layer structure and microcapsule technology, which is applied in the direction of microcapsule preparation and microsphere preparation, can solve problems affecting economic benefits and unfavorable development of the flame retardant industry, and achieve good adaptability, reduce adverse effects, and good water resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

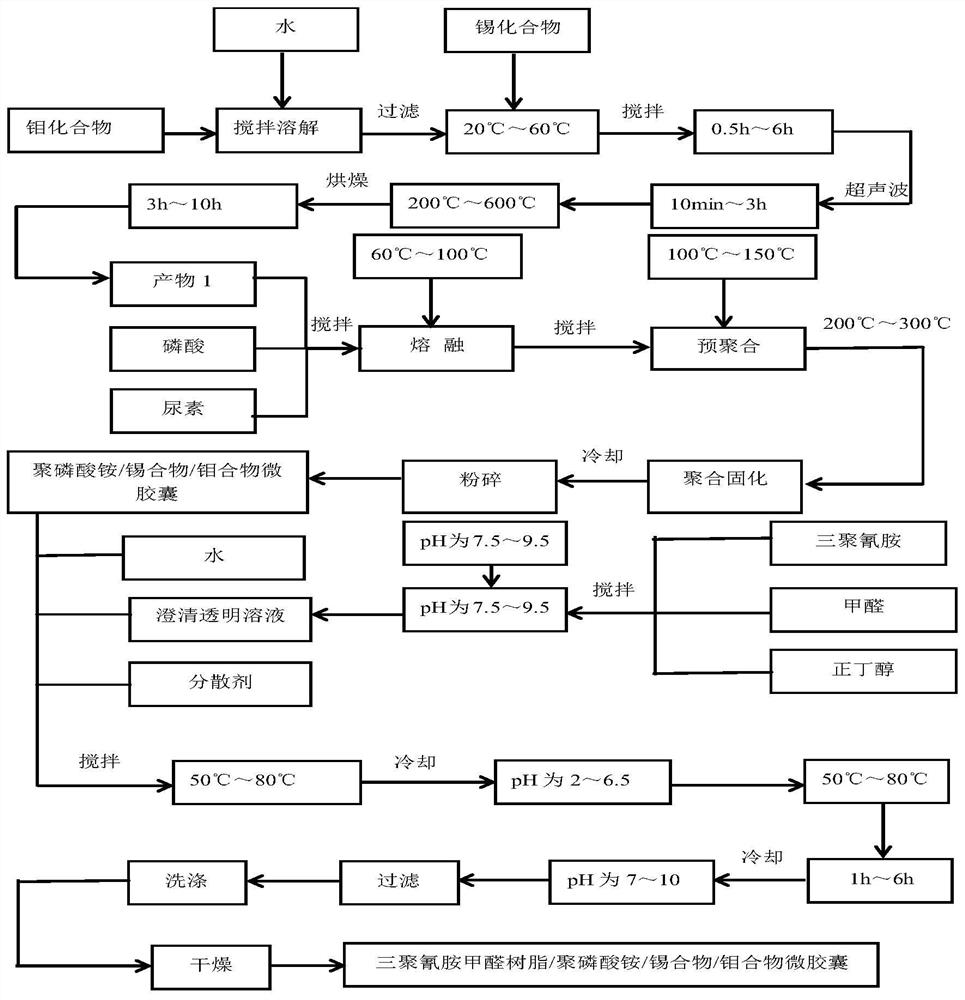

Method used

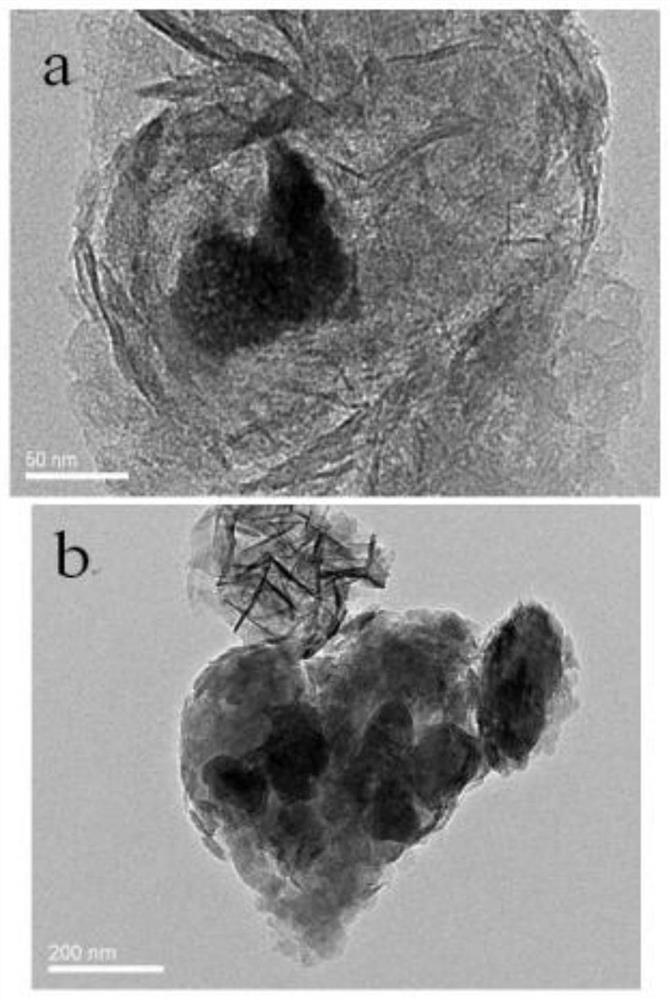

Image

Examples

Embodiment 1

[0042] Example 1 1) Add 3kg of molybdenum trioxide and 10kg of distilled water into the reactor, stir to dissolve, and filter. Then add 6 kg of zinc hydroxystannate into the reaction kettle, mechanically stir at 25°C for 30min, put the product in the ultrasonic wave for 1.5h, and finally place it in a furnace at 250°C for 7h to obtain the product 1. 2) The product 1, the product 1 Add 10% of the total mass of urea and phosphoric acid, 1.6kg urea, and 1kg phosphoric acid into the reaction kettle, connect the tail gas absorption device, heat to 90°C, until the solution becomes clear, the temperature rises to 135°C, react for 2 hours, the solution is viscous Thick, and then put the product in an oven at 210°C for 2.5 hours, cool, and crush to obtain ammonium polyphosphate / tin compound / molybdenum compound microcapsules. 3) Put 12.6kg of melamine, 20.29kg of formaldehyde, and 20.76kg of n-butanol in Reactor No. 1, heat to 70°C, and use 10% Na 2 CO 3 Adjust the pH to 8.5 to obtain...

Embodiment 2

[0043] Example 2 1) Add 3kg of molybdenum trioxide and 10kg of distilled water into the reactor, stir to dissolve, and filter. Add 6 kg of zinc hydroxystannate into the reaction kettle, mechanically stir at 25°C for 30 minutes, place the product in ultrasonic waves for 1.5 hours, and finally place it in a furnace at 250°C to dry for 7 hours to obtain the product 1. 2) The product 1, the product 1 is Add 20% of the total mass of urea and phosphoric acid, 1.6kg urea, and 1kg phosphoric acid into the reaction kettle, connect the tail gas absorption device, and heat to 90°C until the solution becomes clear, then the temperature rises to 135°C, react for 2 hours, and the solution becomes viscous Then put the product in an oven at 210°C to react for 2.5 hours, cool, and pulverize to obtain ammonium polyphosphate / tin compound / molybdenum compound microcapsules. 3) Put 12.6kg of melamine, 20.29kg of formaldehyde, and 20.76kg of n-butanol in Reactor No. 1, heat to 70°C, and use 10% Na ...

Embodiment 3

[0044] Example 3 1) Add 3kg of molybdenum trioxide and 10kg of distilled water into the reactor, stir to dissolve, and filter. Add 6 kg of zinc hydroxystannate into the reaction kettle, mechanically stir at 25°C for 30 minutes, place the product in ultrasonic waves for 1.5 hours, and finally place it in a furnace at 250°C to dry for 7 hours to obtain the product 1. 2) The product 1, the product 1 is Add 30% of the total mass of urea and phosphoric acid, 1.6kg urea, and 1kg phosphoric acid into the reaction kettle, connect the tail gas absorption device, and heat to 90°C until the solution becomes clear, then the temperature rises to 135°C, react for 2 hours, and the solution becomes viscous Then put the product in an oven at 210°C to react for 2.5 hours, cool, and pulverize to obtain ammonium polyphosphate / tin compound / molybdenum compound microcapsules. 3) Put 12.6kg of melamine, 20.29kg of formaldehyde, and 20.76kg of n-butanol in Reactor No. 1, heat to 70°C, and use 10% Na ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com